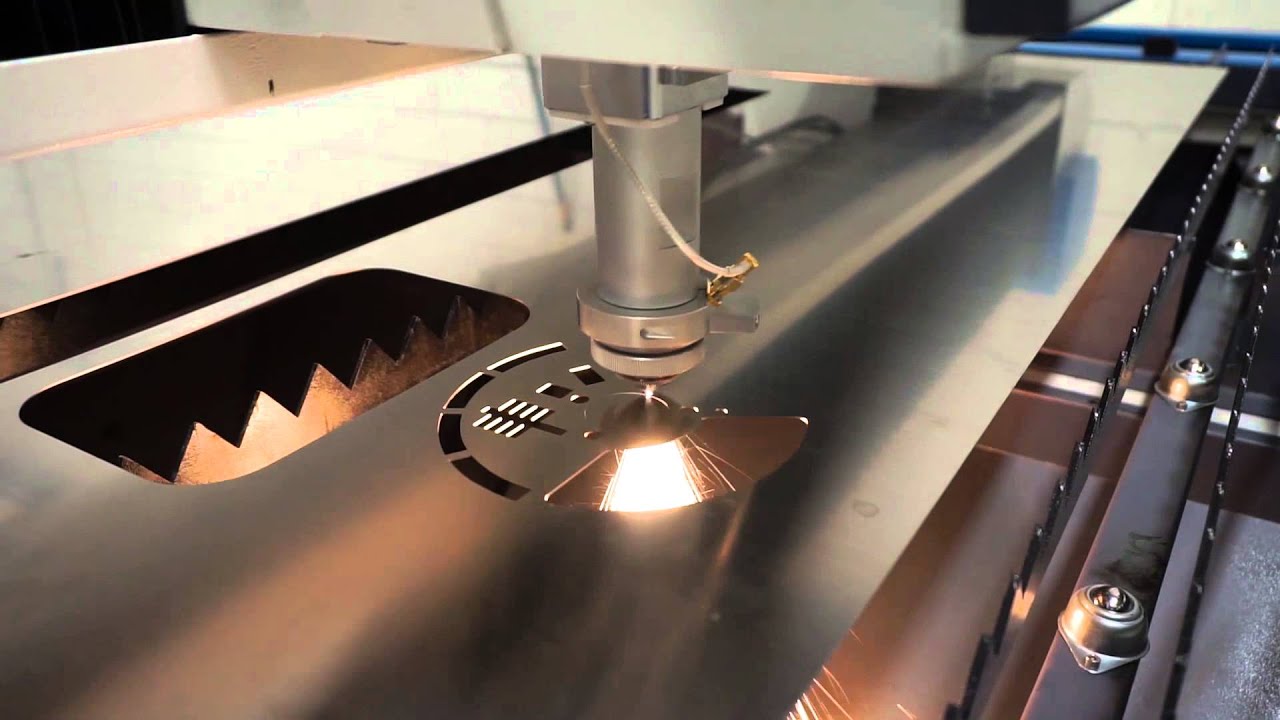

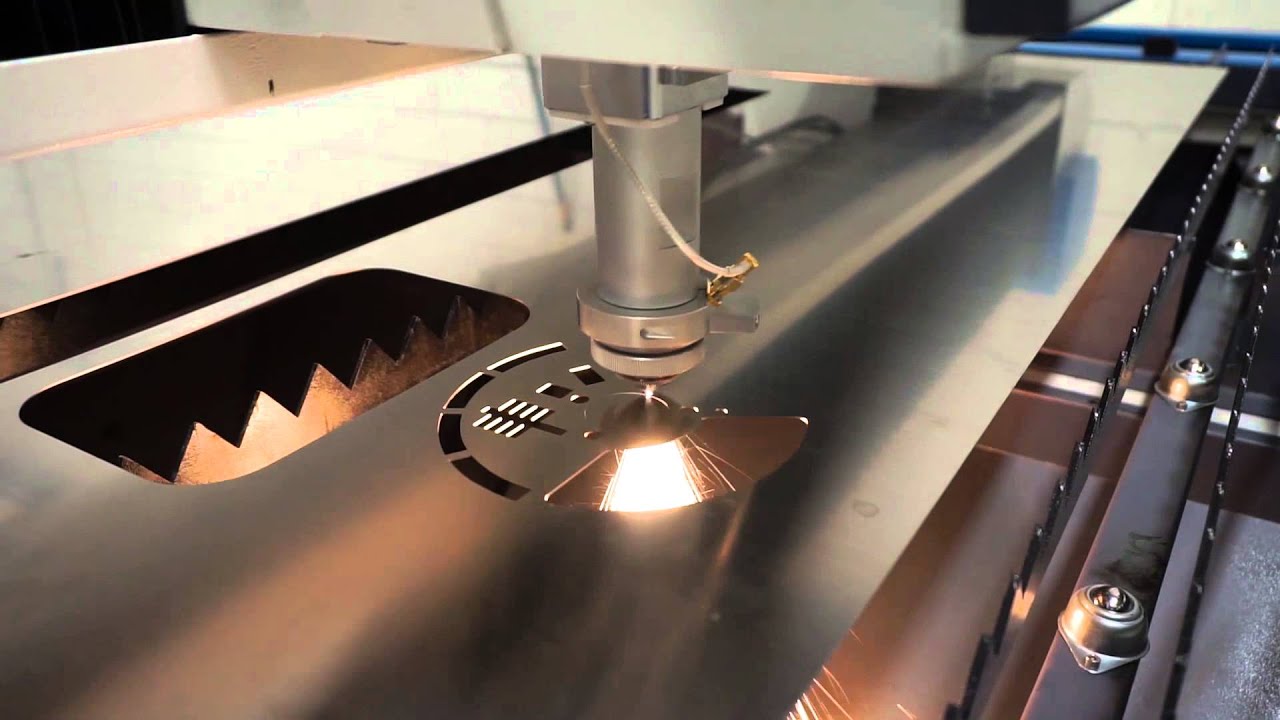

Laser cutting is one of the thermal cutting methods. It uses a focused high power density laser beam to irradiate the workpiece to rapidly melt, vaporize, ablate or reach the ignition point of the irradiated material. At the same time, the molten material is blown away with the help of a high-speed airflow coaxial with the beam. , so as to realize the cutting of the workpiece.

Fiber laser cutting is suitable for cutting stainless steel, carbon steel, aluminum alloy, brass and other metal materials, and has the characteristics of no external force contact, fast cutting speed, and smooth incision during cutting. Therefore, it has been widely used in industrial production.

Usually, the important process parameters that affect the cutting quality are cutting speed, laser power, auxiliary gas, focus position, nozzle characteristics and material properties. It can be seen that there are many factors affecting the laser cutting process. If the control is improper or the parameters are not accurately grasped, the cutting accuracy and cutting quality will be greatly affected. In actual processing, how to accurately, quickly and effectively grasp the above-mentioned key factors affecting the quality of fiber cutting is very important.

When laser processing stainless steel and aluminum-zinc plate, the workpiece has burrs

When this happens, we must first consider the factors that cause burrs when cutting stainless steel, and we cannot simply accelerate the cutting speed, because the added speed sometimes causes the plate to not be cut, especially when processing galvanized steel. phenomenon is particularly prominent. At this time, other elements of the fiber laser cutting machine should be considered to solve, such as whether the nozzle needs to be replaced, and the movement of the guide rail is unstable.

Analysis of the Deformation of Small Holes During Cutting

This is because the machine tool does not adopt the method of explosive perforation during processing, but uses the method of pulse perforation, which makes the laser energy too concentrated in a small area and burns the non-processing area, resulting in the deformation of the hole and affecting the Processing quality. At this time, the pulse piercing method should be changed to the explosive piercing method during processing. For the fiber laser cutting machine with lower power, it is just the opposite, and the pulse perforation method should be adopted in the processing of small holes to obtain a better surface finish.

Solutions for abnormal sparks in low carbon steel processing

This condition will affect the machining quality of the part's cutting and section finish. At this moment, when other parameters are normal, the following questions should be considered: 1. The loss of the laser head nozzle? The nozzle should be replaced in time. If there is no new nozzle to be replaced, the gas pressure of the cutting operation should be increased; 2. Is the thread at the connection between the nozzle and the laser head loose? At this moment, the incision should be stopped immediately, the connection status of the laser head should be checked, and the thread should be re-threaded.

Our service - to solve any laser problems for you

Our service - to solve any laser problems for you

In order to better serve and return customers, and let our equipment create better value for users,

Baiweiser Laser has established a user training center based on the tenet of "customer first, service first", using its own resources to provide free training for life and warranty. Waiting for a one-stop service to share with you how to use lasers in production and creation to solve problems, improve processes, increase efficiency, and save costs.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)