Tube laser cutting is a non-contact cutting method that is very necessary in the entire future market. There will be no pressure during the processing of the pipe wall of the pipeline, nor will it collapse and deform. At the same time, when laser cutting pipes, the treatment of pipe cracks is also very good.

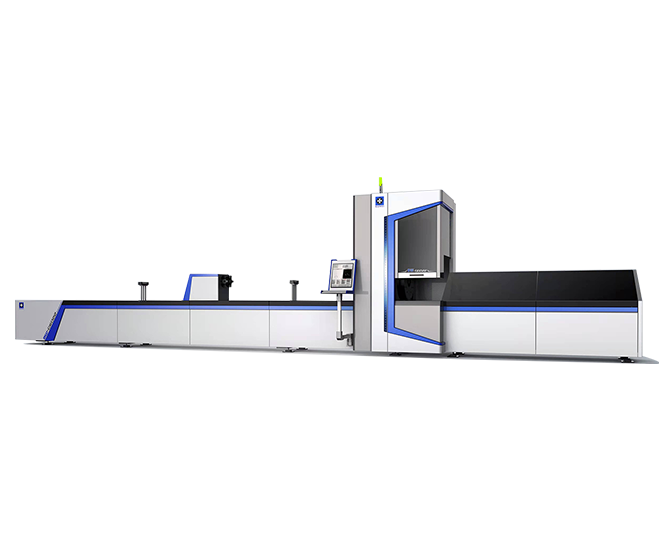

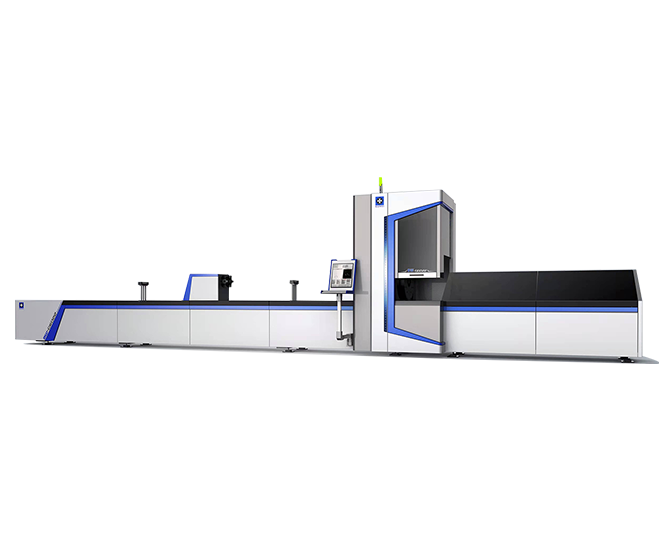

Tube laser cutting machine, specially designed for metal tube laser cutting. The double-chuck structure can cut metal tubes with a diameter of 20-500mm, maximum tube diameter we can do is 500mm, this is the largest model in this industry.equipped with a 1000w-6000w fiber laser, and the tube length can reach 3m, 6m, 9m, 10m ,12m etc. 2000w and above. The power supply is equipped with an independent cabinet and built-in air conditioner, and can be equipped with an automatic loading and unloading device to realize automatic processing.

•Wide Cutting Applications

Applied in carbon steel, stainless steel, alloy steel and other metal types cutting.

•Special Profiles of Tubes

Applied in U-shaped, L-shaped, I-beam, rectangular, oval and other irregular profile and tube types cutting.

•Auto Pneumatic Chucks

The tube cutting machine is highlighted with excellent tightness and motional characteristics, the chucks can stably clamp a variety of tube materials as square, round, oval, flat, triangular, L-shaped, I-beam

•Powerful and User-friendly Nesting software

Professional tube cutting software and matching nesting software are implemented to draw graphics or text at random or instant processing, giving handy processing, simple and easy using experience.

Sample Display

.png)

We provide some frequently asked questions:

The light pipe cutting machine to cut various metal thin-walled pipes has the advantages of good cutting effect, fast speed and economic stability. High quality cutting. The laser tube cutting machine has fast processing speed and high precision! So what should I do if the laser cutting machine encounters problems when cutting the tube?

First, the cutting point of the parts is over-burned, the corners of the parts are over-burned, the cutting surface is inclined, and the circle is deformed or cannot be closed when cutting round parts, which directly leads to serious waste of pipes and low pipe cutting production efficiency.

solution:

Familiar with laser tube cutting technology, especially the operating experience of technicians. The laser tube cutting control software has provided advanced tube cutting software and rich tube cutting technology, so if the technicians who have trained themselves are trained and skillfully use the control system, they can achieve high-quality and high-efficiency CNC cutting.

Second, in the pipe cutting process, the molten slag adheres to the inner wall of the pipe during pipe cutting (especially for square pipes with small diameters), and most of the heat generated by cutting is absorbed by the workpiece. The corners and the four corners of the square tube are too burned, which seriously affects the quality of the incision, and even cannot be cut.

solution:

1. The method of increasing the oxygen pressure;

2. Improve the speed of sharp corner synthesis through software;

3. The laser cutting head with height sensing follow-up system can ensure that during the cutting process, the height of the cutting nozzle and the surface plane of the workpiece remains unchanged (the focus remains unchanged), so that the cutting effect is not affected by the change of the workpiece surface.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)

.png)