Features of Closed Type Fiber Laser Cutting Machine

● In closed processing environment, dust proof, smoke proof, safe and environmentally friendly;

● With overall heavy-duty gantry structure machine tool and high-strength cast aluminum crossbeam, which has good rigidity and stable performance;

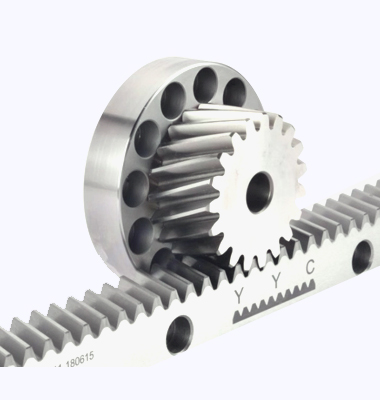

● Imported transmission device is perfectly matched with the servo system to ensure cutting accuracy and efficiency.

● Professional laser cutting CNC system, automatic edge seek function, automatic nesting, improve utilization rate and production efficiency.

● High-speed exchange table can be selected to simplify the work process and save time.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)