In the hot summer, the temperature rises and the air humidity is also high, and some mechanical equipment will inevitably fail. People often say that sharpening knives does not accidentally chop woodworkers. Scientific maintenance of

laser cutting machines can not only avoid some small faults, improve cutting efficiency, but also Improve the service life of some accessories.

一、Avoid condensation

The difference between the cooling water temperature and the air temperature should not be too large. Both the laser and the optical lens of the laser cutting machine use the water cooling method. Since the water in the air will condense into water when it is cold, when the temperature of the cooling water is 5-7 degrees lower than the room temperature, the surface of the laser and the optical lens will condense water. Condensation greatly affects the light extraction efficiency of the laser and the transmission of the optical lens, which has a great impact on the laser energy and the service life of the optical components. It is recommended that most laser cutting machine users set the water temperature to 30-32 degrees, and control the temperature difference between the cooling water temperature and room temperature to be greater than 7 degrees. Hot and humid weather can also cause wetting or condensation inside and outside the RF laser. The outer wall and periphery of the glass laser tube, the laser power supply and various parts of the laser equipment will cause various failures, which will seriously affect the normal production of users. Failures due to the above reasons are not covered by the normal warranty.

At this point you should pay attention to:

1. When the laser equipment is turned off, the water cooler should also be turned off. Close to prevent moisture or condensation due to excessive temperature difference; 2. It is recommended that the air conditioner not be turned off in harsh environments to maintain a constant temperature in the room. Or every time you turn on the power, turn on the air conditioner for half an hour, then turn on the water cooler and laser equipment. 3. The laser equipment adopts a smooth and open design. It is recommended to isolate the air-conditioned room and control the temperature and humidity of the room, which is equivalent to the laser equipment working in the isolated space (no dust, no constant humidity), which can effectively avoid moisture or condensation and high temperature. failure.

二、Maintain the cooling system, cooling water

When the temperature rises in summer, the working pressure of the cooling system of the laser cutting machine increases. It is advisable to check the internal snow pressure of the cooler before the heat arrives. Different manufacturers have different pressures. It is recommended to consult the equipment manufacturer's specific parameters before maintenance. In summer, the deterioration rate of cooling water is also accelerated due to the higher temperature. It is recommended that users of the

laser cutting machine use regular distilled water or pure water, and clean the scale regularly to avoid the laser and pipe scale affecting the laser power. The method of cleaning the scale by different types of laser cutters is also different. Follow the device manufacturer's instructions.

三、Guide rail maintenance

The guide rails should be cleaned frequently to remove dust and other debris, be sure to wipe and lubricate the normal bracket of the laser device frequently to ensure lubrication and debris free. Regular cleaning and lubrication will keep the machine in a better position during processing, the cutting will be more precise and the quality of the cut product will be improved.

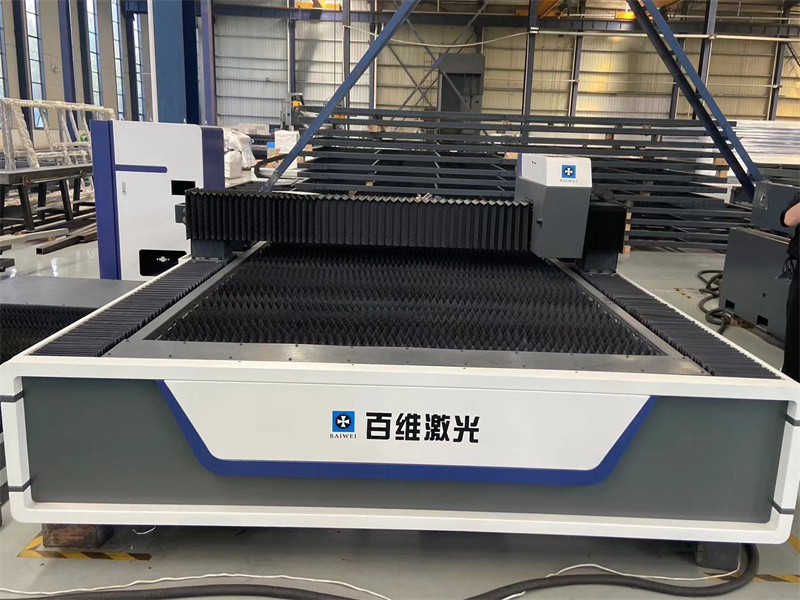

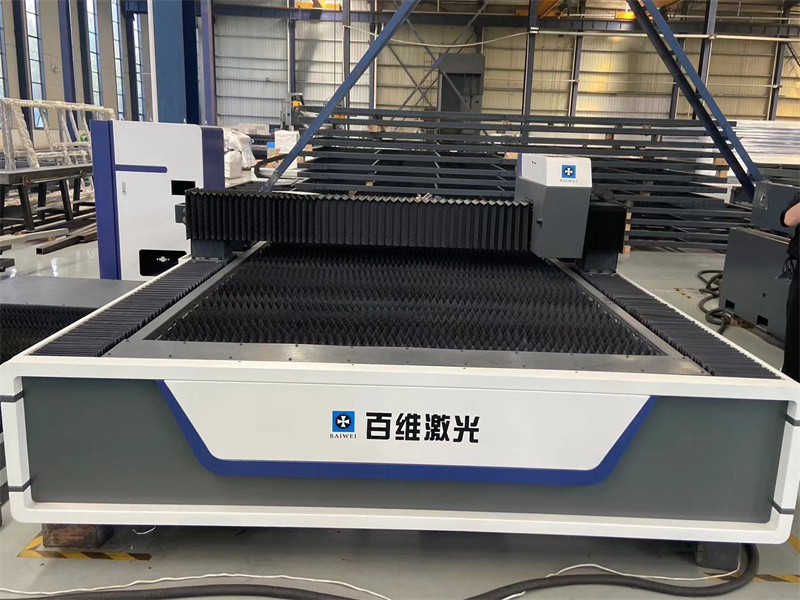

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)