Stainless steel pipes are more and more widely used, and laser cutting machines are used by many stainless steel product enterprises. Especially in recent years, with the development of automation technology, laser cutting machines with automatic loading and unloading are also available.

The laser cutting machine is controlled by a digital system, which is also one of the advantages of the laser cutting machine for cutting pipes. First of all, to ensure accuracy and flexibility, laser tube cutting technology can process any shape that has been programmed, and can be cut in any direction. The shape of the template can be changed quickly without the help of any tools. As long as the design can be modified at the last minute, it will not affect the entire product production process.

.jpg)

Laser tube cutting machine is an advanced stainless steel tube processing equipment, but if you don't pay attention when using it, it will still cause problems such as poor tube cutting quality and material waste, which will invisibly increase the manufacturing cost of the enterprise, so how to improve the laser Efficiency of the pipe cutter?

At present, there are quality problems in the process of laser tube cutting, such as over-burning of the cutting point of the parts, over-burning of the corners of the parts, tilting of the cutting surface, and circular deformation or inability to close when cutting round parts, which directly lead to serious waste and cutting of pipes. Tube production efficiency is low.

Pipe cutting process Since the slag is attached to the inner wall of the pipe when the pipe is cut (especially for the small diameter square pipe), most of the heat generated by the cutting is absorbed by the workpiece. The four corners of the square tube are over-burned, which seriously affects the quality of the incision, and even cannot be cut.

For such issues:

1. The method of increasing the oxygen pressure;

2. Improve the speed of sharp corner synthesis through software.

3. The laser cutting head with height sensing follow-up system can ensure that during the cutting process, the height of the cutting nozzle and the surface plane of the workpiece remains unchanged (the focus remains unchanged), so that the cutting effect is not affected by the change of the workpiece surface.

In view of the above-mentioned solutions, targeted solutions are bound to improve the efficiency of

laser tube cutting and processing equipment, thereby improving the problem of low tube cutting efficiency, poor tube cutting quality, causing serious waste of tubes, and improving the efficiency of enterprises in producing and processing products. , to create better profits for the enterprise.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

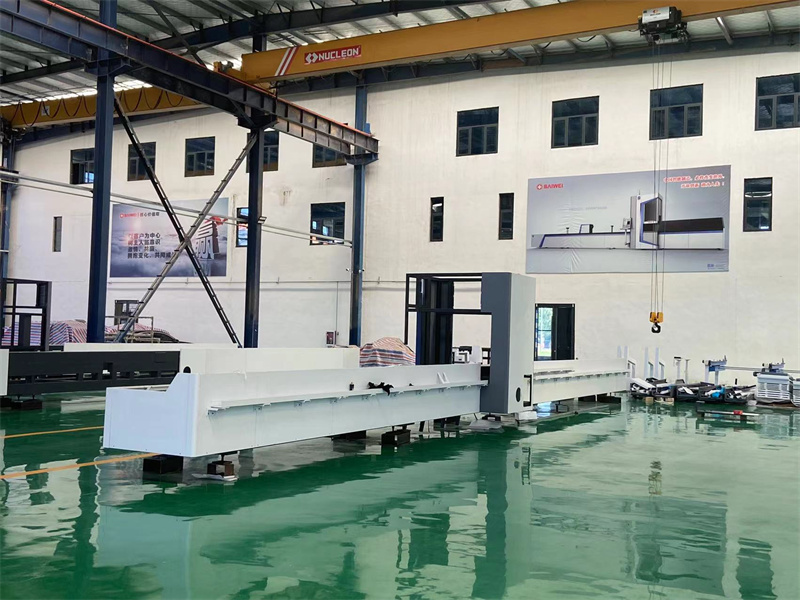

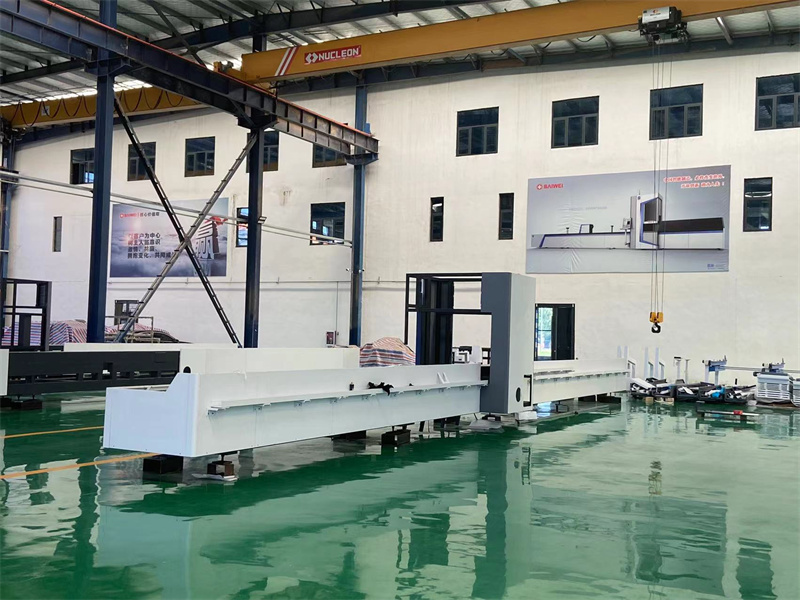

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)

.jpg)