- home

-

products

-

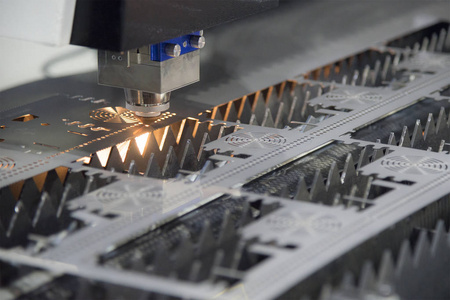

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine -

BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine -

BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine -

BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine -

BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine -

BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine -

BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine -

.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

-

- solution

- about us

- services

- case

- news

- contacts

.jpg)

.jpg)