Basic Structure Of CNC Milling Machine

There are various forms of

CNC milling machines. Although different types of CNC milling machines are different in composition, they have many similarities. The following takes the XK5040A CNC vertical lift table milling machine as an example to introduce its composition. ⅪSaw 040A CNC vertical lift table milling machine is equipped with IV four 3MA CNC system, which adopts full digital AC servo drive. The machine consists of 6 main parts. That is, the bed part, the milling head part, the worktable part, the transverse feed part, the lifting table part, the cooling and lubricating part. The internal layout of the bed is reasonable and has good rigidity. There are 4 adjusting bolts on the base to facilitate the horizontal adjustment of the machine tool. The cutting fluid storage tank is located inside the machine base.

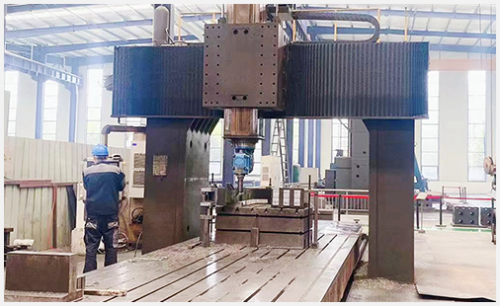

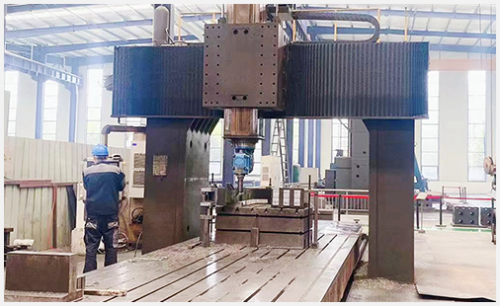

CNC Milling Machine Processing

CNC Milling Machine Processing

The shape of the machined surface of the milling machine is generally composed of straight lines, arcs or other curves. Ordinary milling machine operators according to the requirements of the drawing. Constantly changing the relative position between the tool and the workpiece, and then coordinating with the selected milling cutter speed, the tool can cut the workpiece, and various shapes of workpieces can be processed.

CNC milling machine processing is to divide the motion coordinates of the tool and the workpiece into the smallest unit amount, that is, the smallest displacement amount. According to the requirements of the workpiece program, the numerical control system moves each coordinate by several minimum displacements, so as to realize the relative movement of the tool and the workpiece to complete the machining of the parts.

CNC Milling Machine Safe Guide Precautions

The CNC milling machine is a mechatronic product with high precision requirements. Incorrect operation or brutal operation will seriously damage the accuracy and performance of the machine tool. In order to use and operate the CNC milling machine correctly and ensure the normal operation of the CNC milling machine, the operator must read carefully The manual of the CNC system, familiar with the operating procedures of the milling machine. When operating the CNC milling machine, you should pay attention to the following aspects:

1. After the program is programmed, it should first run dry once to ensure the correct path, feed and speed, and then carry out single-section trial machining to ensure that it is correct.

2. In case of emergency, you can press the red emergency stop button to stop the machine tool immediately, and close all output functions, such as spindle rotation, coolant, etc. After the accident is dealt with, release the emergency stop button to release the closed function, but all output functions must be restarted.

3. If the tool enters the forbidden area specified by the parameters, the CNC system will display an overtravel alarm, and the tool will stop moving. At this time, manually move the tool in the opposite direction, and press the reset button to cancel the alarm. If the machine tool travel hardware limit is exceeded , then press the cancel limit button on the panel, move in the opposite direction in manual mode, and press the reset button to cancel the alarm.

4. When the numerical control system alarms, the operator does not need to panic, and can check the manual to deal with it accordingly. If the alarm information cannot be removed, please ask the maintenance personnel to support. Note: Abnormal situations should be dealt with in time to prevent accidents.

5. Remember not to press the panel with hard objects and dirty hands, in order to prevent the mask from being broken, sundries and water entering the keyboard, which will cause the keys to fail.

The Safe Guide Rules Of CNC Milling Machine

1. Basic precautions for safe operation:

The Safe Guide Rules Of CNC Milling Machine

1. Basic precautions for safe operation:

(1) Please wear work clothes, safety shoes, work caps and protective glasses during operation. Gloves are not allowed to operate the machine.

(2) Do not move or damage the warning signs installed on the machine tool.

(3) Do not place obstacles around the machine tool, and the working space should be large enough.

(4) When a certain job requires two or more people to complete it together, attention should be paid to mutual coordination.

(5) Compressed air is not allowed to clean machine tools, electrical cabinets and nc units.

2. Preparations before operation:

(1) The machine tool should be preheated before working, and the lubrication system should be carefully checked for normal operation. If the machine tool has not been started for a long time, oil can be supplied to each part manually first.

(2) The tools used should conform to the specifications allowed by the machine tool, and the tools with serious damage should be replaced in time.

(3) Do not forget the tools used to adjust the tool in the machine tool.

(4) After the tool is installed, one or two trial cuttings should be carried out.

(5) Check the status of the chuck clamping work.

3. Safety precautions during operation:

(1) It is forbidden to touch the tool tip and iron filings by hand, and the iron filings must be cleaned with iron hooks or brushes.

(2) It is forbidden to touch the rotating spindle, workpiece or other moving parts by hand or in any other way.

(3) It is forbidden to measure and change the speed during the processing, let alone wipe the workpiece with cotton yarn, nor clean the machine tool.

(4) When the CNC milling machine is running, the operator shall not leave the post, and should stop immediately when abnormal phenomena are found.

(5) Check the bearing temperature frequently. When the temperature is too high, you should find relevant personnel to check.

(6) During the processing, it is not allowed to open the protective door of the machine tool.

(7) Strictly abide by the post responsibility system.

4. Notes after the operation is completed:

(1) Remove chips and wipe the machine tool to keep the machine tool and the environment clean.

(2) Check the state of lubricating oil and coolant, and add or replace it in time.

(3) Turn off the power supply and the main power supply on the machine tool operation panel in turn.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)