When laser processing carbon steel, novice operators may encounter some problems, such as burrs at the bottom of the cutting surface, incomplete cutting, and continuous cutting. Let's analyze the reasons in detail.

一、There are burrs at the bottom of the cutting surface. The reasons are:

1. Focus issues. The focal position of the laser is wrong, and this problem can be solved by adjusting the focus.

2. Laser output power problem. First, check whether the laser is normal. On the premise that the laser is working normally, further check whether the output power of the laser matches the required power of the plate. If it does not match, it needs to be adjusted.

3. Cutting speed problem. If the cutting speed is too slow, burrs will appear at the bottom of the cutting surface. In this case, the cutting speed needs to be accelerated.

4. Gas problem. The purity of the gas can also affect the quality of the cutting. When the gas purity is not enough, such problems will also occur, and it is necessary to replace the gas with a higher purity for cutting.

5. The working time of the machine is a problem. When the machine works continuously for more than a certain time, such problems may also occur, and the machine needs to be restarted at this time.

二、The cutting is not complete and the cutting is continuous. The reasons are as follows:

二、The cutting is not complete and the cutting is continuous. The reasons are as follows:

1. The cutting speed is too fast. When the cutting speed is too fast, it is easy to see the phenomenon that the cutting is not transparent, and it is very easy to occur when cutting thicker plates. At this time, the cutting speed should be properly controlled, and the speed should not be pursued.

2. Improper selection of nozzles. The hole diameter of the nozzle does not match the thickness of the sheet, and more nozzles are needed to solve the problem.

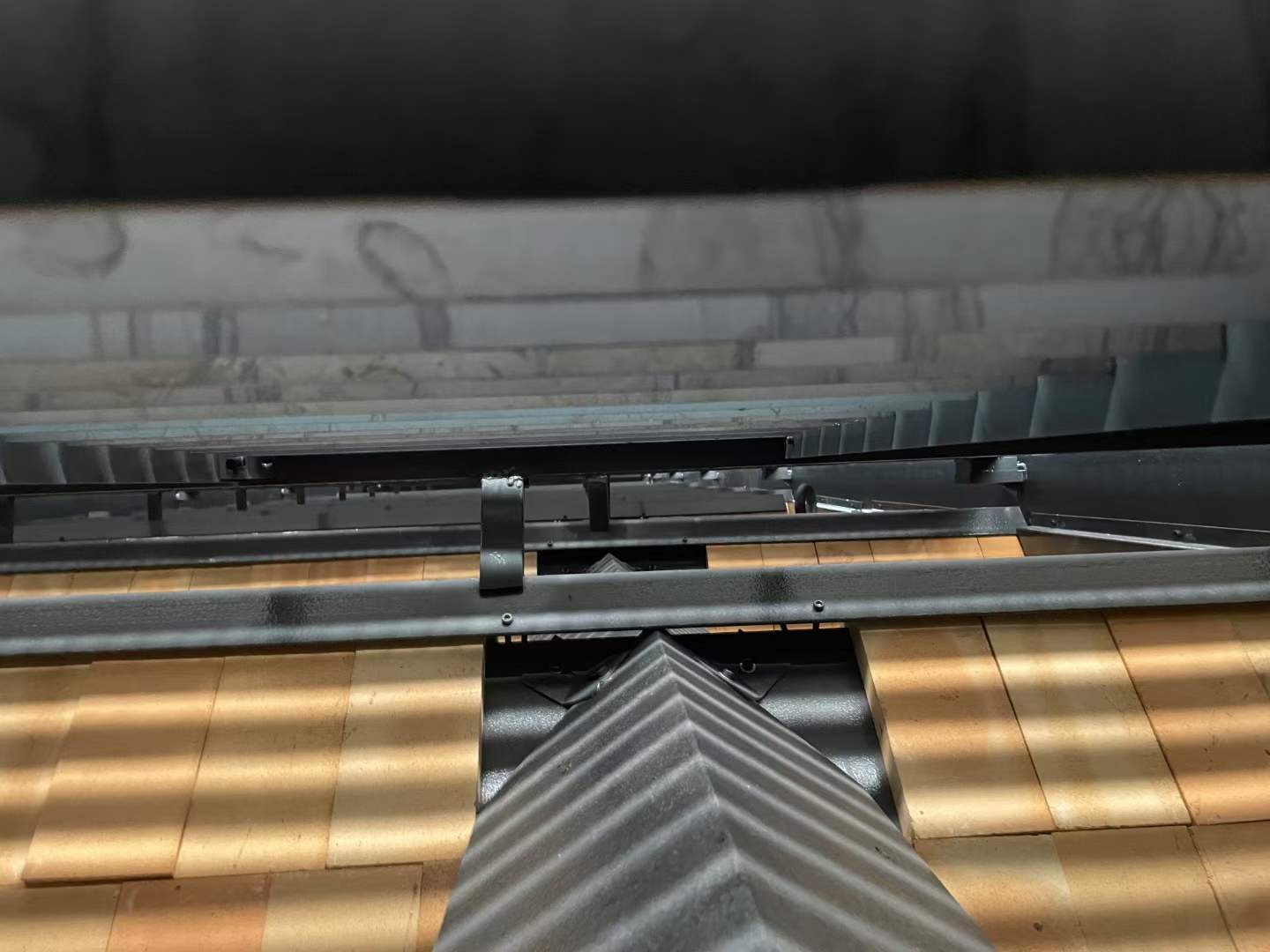

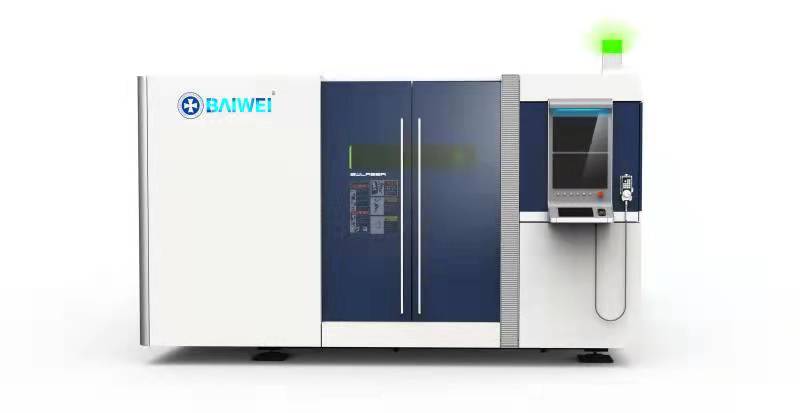

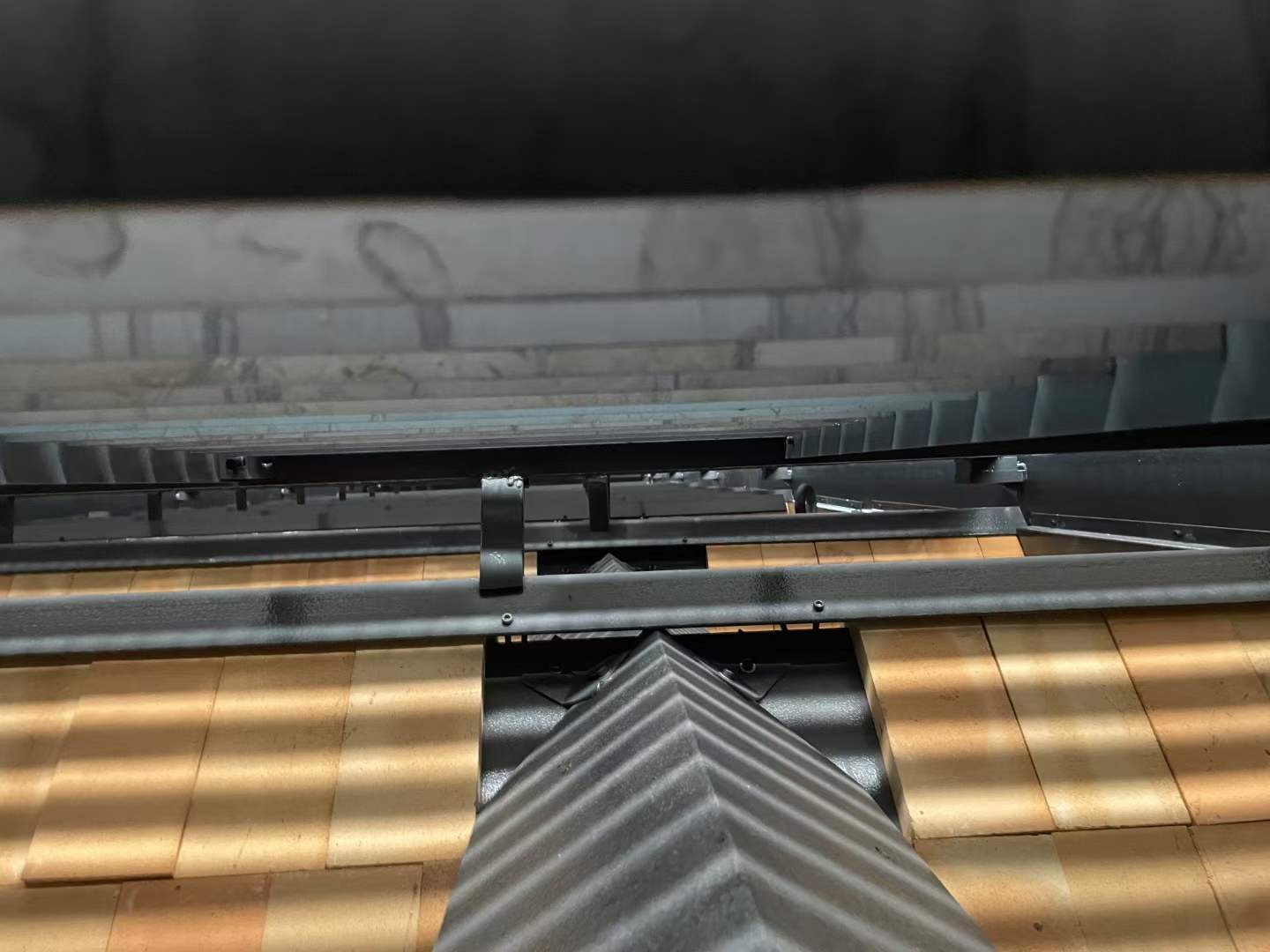

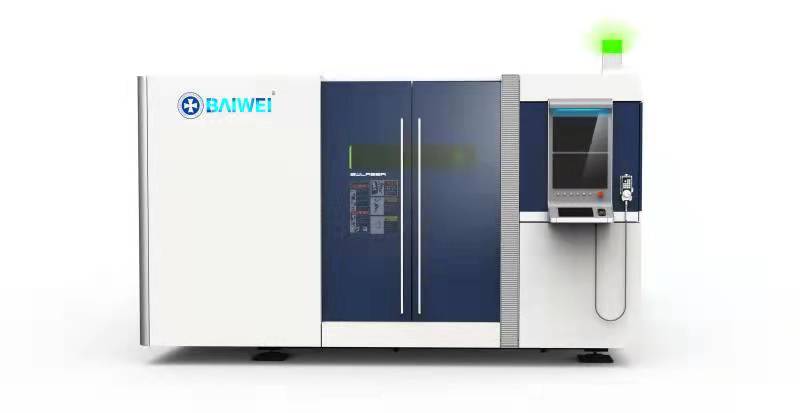

Baiwei's closed fiber laser cutting machine adopts high-strength cast aluminum alloy beams, which can effectively ensure cutting accuracy; closed cutting cabinets reduce noise and ensure safe operation; the whole set of equipment is equipped with a dedicated laser cutting control system and automatic follow-up focusing system; Real-time automatic adjustment of the focus following the bending and fluctuation of the workpiece to ensure cutting quality and precision; at the same time, it is equipped with a high-efficiency dust removal system to create a good working environment.

Therefore, Baiwei's

closed fiber laser cutting machine can be widely used in sheet metal processing, advertising sign production, high and low voltage electrical cabinet production, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, eye industry , spring sheets, circuit boards, electric kettles, medical microelectronics, hardware, knives and measuring tools and other industries.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)