In 2020, an epidemic has accelerated the pace of intelligence and automation in metal processing. Manufacturing upgrades and automatic production have become the focus of the market, and the same is true for the pipe and profile processing industry. Before that, Laser Intelligent Equipment Group attached great importance to the construction of intelligent factories, innovating, developing and producing laser intelligent equipment, constantly meeting the new demands of the market, and creating great economic benefits and value for customers. It is precisely with the rapid growth of the metal pipe market that the market has put forward higher requirements for the processing quality, technology and cutting technology of pipes and profiles. Traditional metal steel pipe processing has poor processing accuracy, low production efficiency, and poor cutting quality. The material utilization rate has been unable to meet the needs of the metal pipe market.

Metal pipes are widely used in different industries. Due to different application scenarios, parts of different shapes and sizes need to be processed to meet the needs of different industries. Laser processing technology was born for this reason, and it is very suitable for the processing of various metal pipes. The tube laser cutting system has the characteristics of high flexibility and high automation, and can realize the production of small batches and varieties of different materials.

In foreign countries, the degree of automation of

laser pipe cutting machines is relatively high, which can realize automatic loading, unloading and automatic centering and clamping of pipes. It is suitable for cutting various types of pipes, but its localization services cannot be guaranteed quickly; The degree of automation is low, mostly manual loading, unloading and manual clamping, and the labor intensity of workers is too high. Based on the above development of domestic and foreign markets, domestic pipe cutting equipment has problems such as low degree of automation, poor cutting quality and low efficiency. For this reason, we have provided a fully automatic laser pipe cutting machine for the pipe processing market through in-depth research through market analysis.

By analyzing the market demand for pipe cutting equipment, guided by the development of laser technology, drawing on advanced processing technology, concentrating on the field of pipe processing, and deeply researching related core technologies, we provide pipe processing customers with automatic laser pipe cutting machines to achieve different loading and unloading materials. Length, different pipe diameters, different shapes of pipes and profiles, orderly workpiece feeding, clamping, rotation, cutting, feeding, cutting, blanking and other one-stop mass production services.

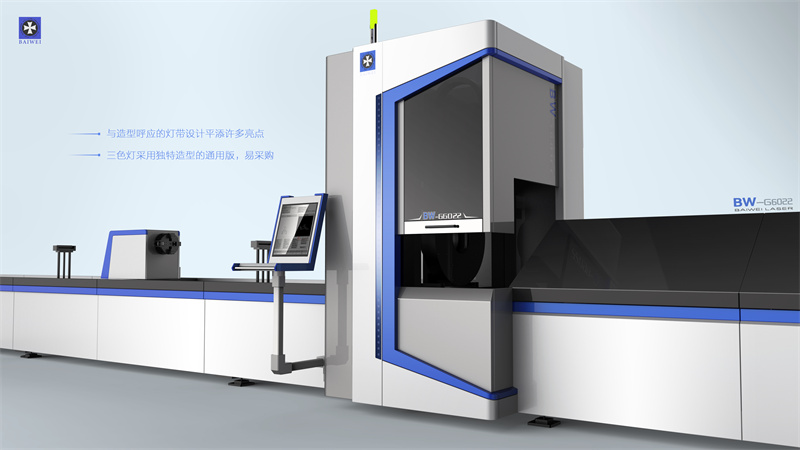

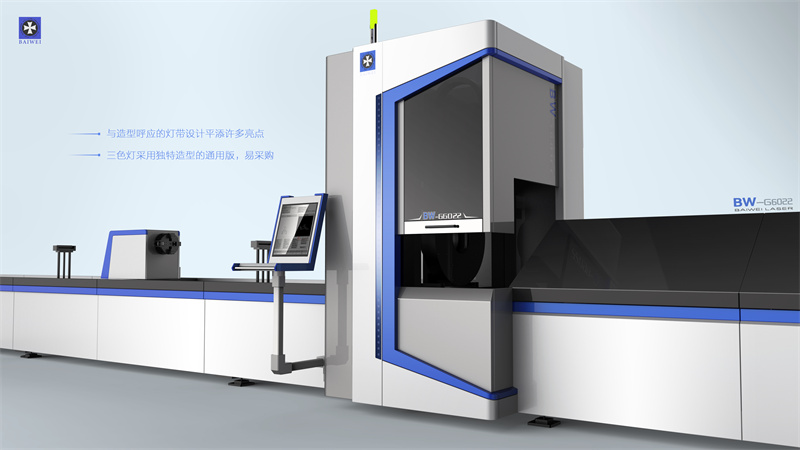

This is a high-power

CNC laser pipe cutting machine that integrates laser cutting, machinery and CNC technology. It can realize fully automatic and high-quality processing of metal pipes, automatic loading and unloading, one-time high-speed cutting and forming, without subsequent deburring treatment, with high-speed , high precision, intelligence and informatization; it can cut square tubes, rectangular tubes, round tubes, oval tubes and special-shaped tubes, as well as angle steel, channel steel, I-beam, T-shaped steel and other profiles; it can cut carbon steel at high speed , stainless steel, aluminum alloy, copper alloy, titanium alloy and other metal pipes; widely used in engineering machinery, oil pipelines, passenger car manufacturing, agricultural and forestry machinery, special vehicles, household appliances, fitness equipment, laser external processing services and other machinery manufacturing pipe processing industry.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)