Sheet metal is a general cold working process for metal sheets (usually below 6mm), including shearing, punching/cutting/compounding, folding, welding, riveting, splicing, forming (such as car body), etc. Its obvious feature is the same. part thickness. my country has gradually become an international processing and manufacturing center. With the continuous increase of foreign investment, the demand for metal processing continues to increase, and electrical control boxes and machine casings in metal processing work are generally sheet metal parts, so sheet metal processing The capacity requirements are also constantly traveling, and the complexity of the process is also relatively high, and even some parts have dozens of processes, which also puts forward higher requirements for sheet metal processing in terms of precision.

At this stage, the problems existing in sheet metal work are as follows: the traditional processing method of sheet metal workshop is to select the technological process of shearing, punching and bending. Among them, the blanking process requires many dies, and the blanking in the sheet metal workshop has the process characteristics of less cutting and no cutting, which is very important.

In this way, when a product is processed, dozens of sets of equipment are generally required, and some products may require hundreds of sets of molds. In terms of time, mold processing requires a certain planning and manufacturing cycle, and the product has a certain trial production cycle, which delays a lot of time. Economically, if many molds are equipped, the cost of the product will travel accordingly, which constitutes a waste of cost.

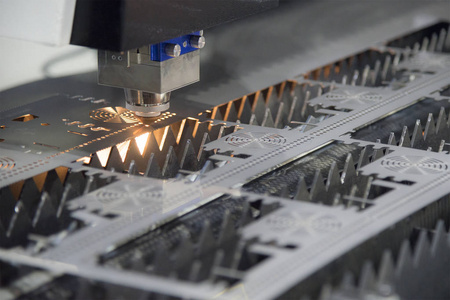

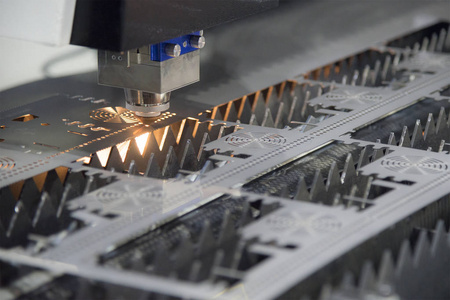

Baiwei's Open type fiber laser cutting machine is a very cost-effective fiber laser cutting machine, as well as an entry-level sheet metal/medium and thin plate cutting and processing equipment. Open type, single platform, simple structure, convenient installation, high precision, high speed, simple operation, convenient maintenance and low operating cost. The beam gantry is made of aviation aluminum die-casting, which has high strength and light weight after high temperature annealing. Dual digital motor drive, front rail design, further enhance acceleration.

Open type fiber laser cutting machine adopts standard bed, stable air control and circuit control system. Its stable characteristics provide us with stable cutting and reduce sheet waste, improve productivity and precision assurance, and the cutting consistency has been greatly improved. Can be used for carbon steel, stainless steel, aluminum, brass and galvanized sheet, etc. It is suitable for sheet metal processing, cabinet production and other kinds of medium and thin plate cutting. It is the first choice for laser cutting machine users.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)