When the laser cutting machine is working, if it breaks down, it is very dangerous. Novices must be trained by professionals before they can operate independently. According to experience, 13 details of laser cutting machine safety work are summarized:

1. Comply with the general cutting machine safety operating procedures. Start the laser strictly according to the laser start-up procedure.

2. The operator must be trained, familiar with the structure and performance of the equipment, and master the relevant knowledge of the operating system.

3. Wear labor protective equipment according to the regulations, and must wear protective glasses that meet the regulations near the laser beam.

4. Do not process a material before it is clear whether it can be irradiated or heated by laser, so as to avoid the potential danger of smoke and steam.

5. When the equipment is in operation, the operator shall not leave the post without authorization or entrust someone to be in charge. If it is really necessary to leave, the operator shall stop the machine or cut off the power switch.

6. Put the fire extinguisher within easy reach; turn off the laser or shutter when not processing; do not place paper, cloth or other flammable materials near the unprotected laser beam.

7. When any abnormality is found during processing, stop the machine immediately, troubleshoot or report to the supervisor in time.

8. Keep the laser, bed and the surrounding area clean, orderly and free of oil, and the workpieces, plates and waste materials should be piled up according to regulations.

9. When using gas cylinders, avoid crushing the welding wires to avoid leakage accidents. The use and transportation of gas cylinders shall comply with gas cylinder monitoring regulations. It is forbidden to expose the cylinder to the sun or close to the heat source. When opening the bottle valve, the operator must stand on the side of the bottle mouth.

10. Follow the high voltage safety regulations during maintenance. Every 40 hours of operation or weekly maintenance, every 1000 hours of operation or every six months of maintenance must be carried out in accordance with regulations and procedures.

11. After turning on the machine, start the machine tool manually at low speed in X and Y directions, and check to see if there is any abnormality.

12. After inputting the new workpiece program, it should be trial-run first and check its operation.

13. When working, pay attention to observe the operation of the machine tool to avoid accidents caused by the cutting machine going out of the effective travel range or two collisions.

It is necessary to consider clearly the scope of your business, the thickness of the cutting material, what material needs to be cut, and then determine the power of the equipment and the size of the workbench that needs to be purchased. Only by choosing the right equipment can we guarantee the potential safety hazards in production.

However, the same fiber laser cutting machine uses different accessories, and the final cutting effect will also be different, so the matching of its accessories is extremely important. Choice of core accessories for fiber laser cutting machine:

1. Fiber laser

The fiber laser is the core component of the laser cutting machine. The service life, cutting speed and cutting quality of the equipment depend to a large extent on the laser.

2. Machine tool structure

The structure of the machine tool is an important factor affecting the cutting accuracy, stability and durability of the small laser cutting machine.

3. Control part

It mainly controls the machine tool to realize the movement of X, Y, and Z axes, and controls the output power and cutting accuracy of the laser, which determine the stability of the laser cutting machine's operating performance.

4. Cutting head

The cutting head is the output device of the fiber laser cutting machine, which consists of a nozzle, a focusing lens and a focus tracking system. Under the control of the control system and the movement of the machine tool, the nozzle moves along the cutting track to realize the cutting of metal materials.

5. Servo motor

The servo motor provides the driving power for the laser cutting machine, and also affects the cutting accuracy. The high-quality servo motor can effectively guarantee the positioning accuracy, positioning speed and repeated positioning accuracy.

6. Laser tube

This is also the heart of the laser cutting machine.

7. Laser lens

The laser lens plays an important role in the laser system, which is related to the power of the laser cutting machine.

8. Cooling device

When the laser is working, it will generate a lot of heat. The cooling device must have safety alarm prompt functions such as ultra-high temperature alarm, flow protection, and water level protection, so as to ensure the constant temperature operation of the fiber laser cutting machine and prolong the life of the fiber laser.

.jpg)

Safe production is the primary focus of any processor, no matter the industry. The premise of production is to ensure the safety of processing and have safe production to improve the efficiency of the company.

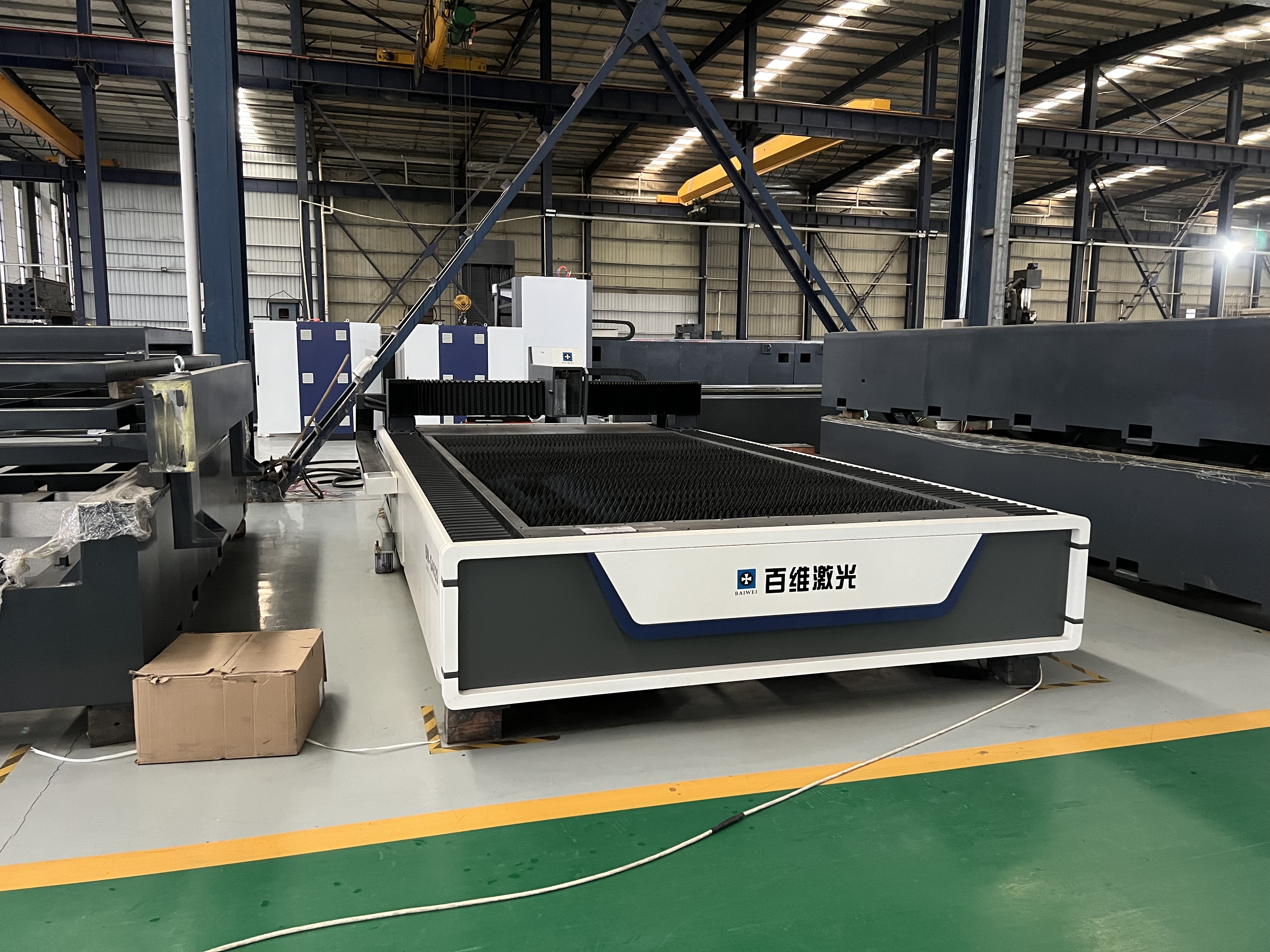

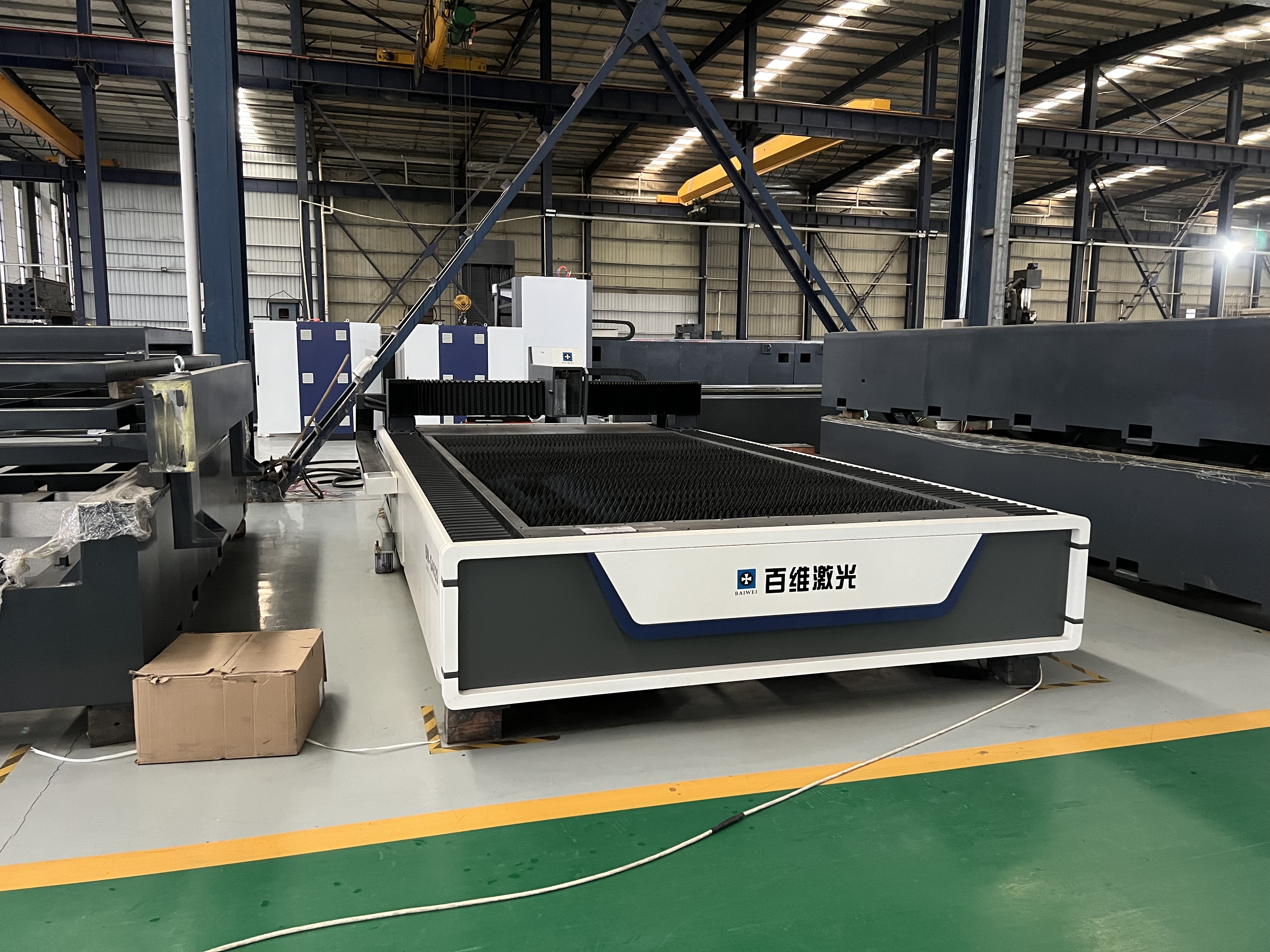

Therefore, the safe operation of

Baiwei laser cutting machine can escort the production of your enterprise!

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)

.jpg)