The thickness of the carbon steel cut by

the metal laser cutting machine is mainly determined by the laser output power. Taking carbon steel as an example, a 1kW metal laser cutting machine can cut 9 thicknesses (that is, 9mm), and 1.5KW can cut 19 thicknesses; while for stainless steel, a 2.5KW laser cutting machine can only cut 15 thicknesses. If If it is thicker, it needs to be equipped with a high-power laser of more than 3kW.

However, for carbon steel plates within 10mm, a fiber laser cutting machine below 1000W can be used for cutting. This is because the cutting width of laser cutting is narrow, generally between 0.1 and 0.5 mm; the cutting accuracy is very high, less than 0.05 mm, and the distance error between the center of the hole is between 0.1 and 0.4 mm, and the error of the outline size is also between 0.1 and 0.1 mm. Between 0.5mm; the cutting section is smooth, and the roughness of the incision is less than 25μm. After the workpiece is cut, it can be directly welded without reprocessing.

For carbon steel plates above 10mm and below 20mm, CO2 metal laser cutting machines of about 2000W can be selected. Because of this thickness of steel plates, domestic fiber laser cutting machines cannot be cut at present. However, compared with wire cutting, CNC plasma cutting and water cutting, CO2 metal laser cutting machine cutting is much more efficient and the cutting cost is much lower.

How to guarantee the cutting quality of metal laser cutting machine? This is a problem that many operators pay attention to, but to solve this problem, we must understand the factors that affect the cutting quality of metal laser cutting machines. Below,

Baiwei Laser will summarize some points for you:

1. The thickness of the material - directly affects the quality of the cutting machine

Laser cutting is suitable for cutting thin plates. The cutting effect of carbon steel below 12mm and stainless steel below 6mm is obvious, the quality is the best, and the efficiency can be guaranteed. For example, when the material thickness is <1mm, the material cut is extremely smooth.

2. Laser output power and mode - directly affects the quality of the cutting machine.

The higher the output power of the laser, the better the cutting quality will be on the same thickness of plate. The higher the fit between the laser cutting mode and the material, the better the cutting quality.

3. Surface roughness - directly affects the quality of the cutting machine

Generally speaking, the flatter the surface of the material, the better the cutting quality. Through independent research and development, Wuhan Huayucheng Laser has an automatic induction system, which can automatically adjust the height of the cutting head according to the different thickness of the material.

4. Focus position - directly affects the quality of the cutting machine

Very simple truth, the focus of laser cutting is right, the precision and accuracy of cutting can meet the requirements.

5. Cutting speed - directly affects the quality of the cutting machine

No matter what kind of material the laser cuts, if the cutting speed and the material match are the best, then the cutting effect at this time is the best, too fast or too slow will affect the effect of laser cutting.

6. The pressure and type of auxiliary gas - directly affect the quality of the cutting machine

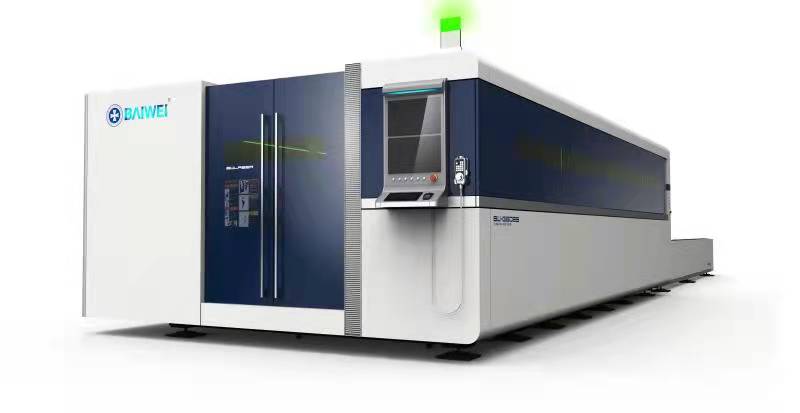

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)