Sheet metal processing has been widely used in all walks of life, and the techniques for cutting metal sheets (under 6mm) include laser cutting, plasma cutting, flame cutting, sheet shearing and punching, etc. Among them, the emerging and booming laser cutting technology in recent years can achieve perfect and effective cutting from micron-scale ultra-thin plates to tens of millimeters thick plates. Compared with traditional cutting methods, laser cutting technology is easier to understand and learn, and has obvious advantages in terms of customized processing effect and speed. We can see that laser cutting technology is developing.

Laser technology is one of the four major innovations of the 19th century, along with atomic energy, semiconductors and computers, it is known as the sharpest knife, the most accurate ruler and the brightest light. However, the barriers to this technology were not broken until the 20th century. The combination of this technology and advanced equipment has promoted the development of advanced equipment manufacturing industry. The technology has penetrated into different fields such as metalworking, steel, aerospace, automobile manufacturing, and medical devices.

When exposed to a high-power and high-density laser beam, the cut object is heated to evaporation temperature for a short period of time and then evaporates along with the formed hole. With a moving beam, the holes formed continuously and then the narrow slits (about 0.1mm) the object is finally cut into pieces, this is how it works. Considering efficiency, speed and precision, laser cutting technology is definitely the first choice in the sheet metal cutting industry. It can cut almost all materials without causing any damage to the material. It can solve the problems of traditional cutting techniques or materials with low cutting quality, such as carbon steel plate.

In recent years, laser cutting technology is becoming a core technology for manufacturers. It can be divided into: laser vaporization cutting, laser fusion cutting, laser oxygen cutting, laser scribing and fracture control cutting. Even better, laser fusion cutting is suitable for all fusible materials, such as metals. The astonishing discovery changed the Doyle (Palmyra) traditional manufacturing method that the company had used for 50 years. The laser cutting machine offered by the Cincinnati company reduces processing time by at least 90 percent, greatly reducing nitrogen consumption.

When people talk about laser cutting, there are many well-known companies that come to mind, and one of them is Hundred. The company is a high-tech company integrating R&D, production and sales, with modern technology and a top research center. Now the company's products include fiber laser cutting machine, CO2 laser cutting machine and engraving machine and fiber laser marking machine.

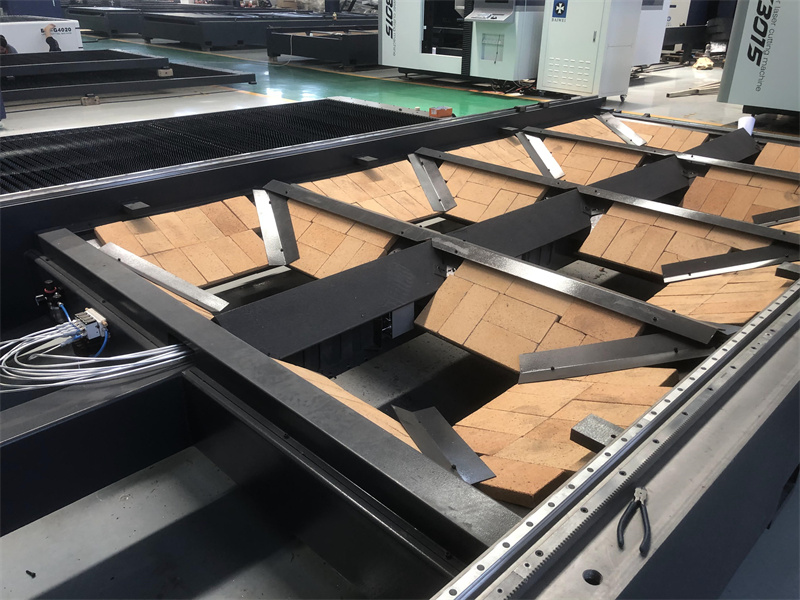

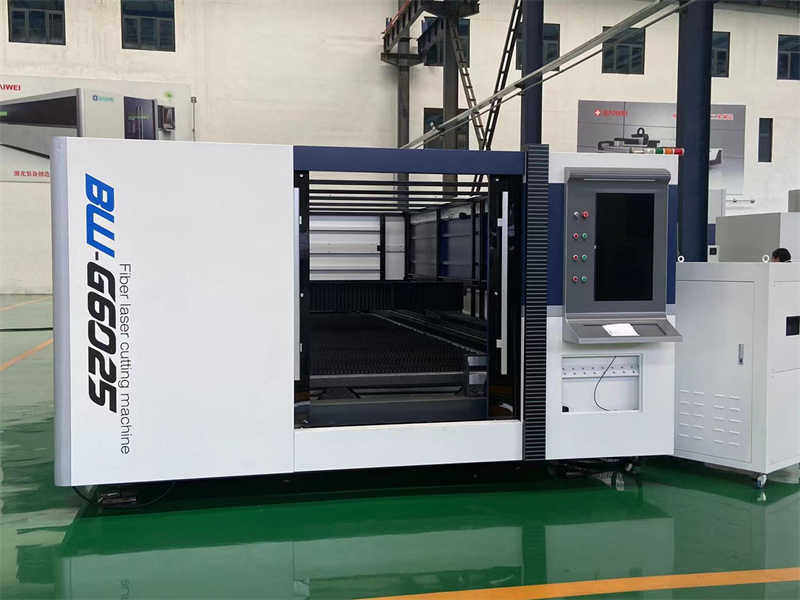

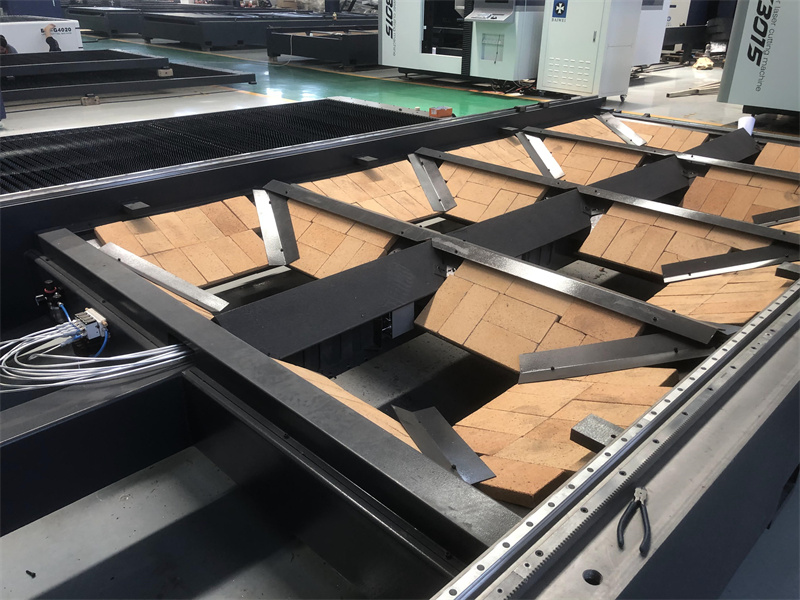

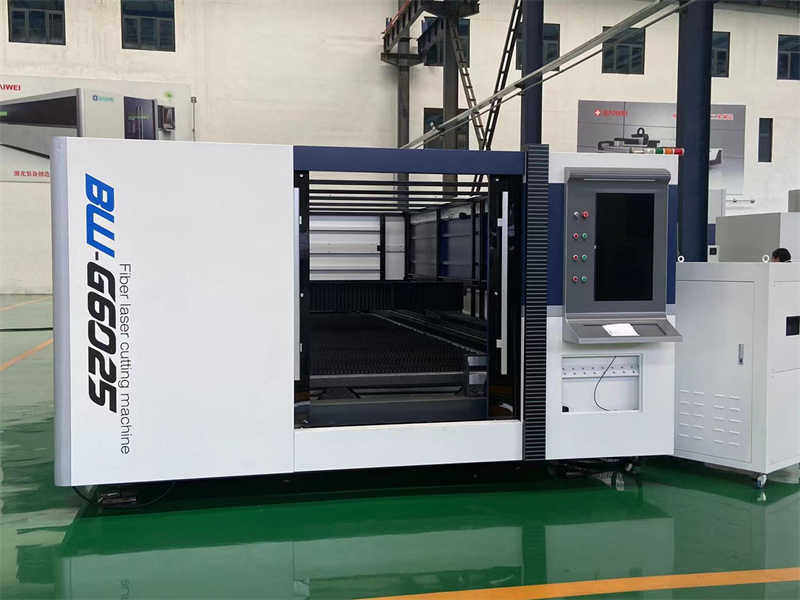

BW-G6025 closed type fiber laser cutting machine is an ideal entry-level product of

Baiwei. It adopts heavy-duty gantry structure machine tool, comprehensive strength and hardness, and has perfect mechanical properties. The machine is equipped with a 500W-12KW laser device, which can meet the requirements of different materials and thicknesses, and the cutting speed is up to 80m/min.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)