I believe everyone is familiar with

laser cutting machines. This kind of equipment is often used in the automotive industry, advertising industry, kitchenware industry, sheet metal processing, cabinet industry, fitness equipment production and other fields. At present, with the increasingly fierce competition in the laser processing industry, how to Improving efficiency and reducing costs have become the concerns of most users.

With the advantages of fast cutting speed, small material deformation, and high processing accuracy, fiber laser cutting machines have quickly become the mainstream of the market. The application of high-power lasers has greatly improved the efficiency of laser processing. The limit cutting speed of thin plates has been able to challenge the control limit of mechanical properties, and the cutting process of medium and thick plates is also constantly breaking through.

Everyone should know a little about carbon steel. It is an iron-carbon alloy with a carbon content of 0.0218%-2.11%, and generally also contains a small amount of silicon, manganese, sulfur, phosphorus and other elements. Theoretically speaking, the higher the carbon content in carbon steel, the greater the hardness and the higher the strength, but the lower the plasticity. So what are the advantages of thin plate laser cutting machine cutting carbon steel plate? Let us briefly understand the advantages of thin plate laser cutting machine cutting carbon steel plate.

For carbon steel processing, the most important thing is to ensure the accuracy of the product, especially some hardware parts, because most of them are used in automobiles, ships, precision parts, and household appliances. The second is the cost saving and benefit increase of the fiber laser cutting machine. In today's increasingly lack of labor, automated production has gradually become the mainstream of the processing industry, so laser equipment that can save labor but enhance efficiency is destined to become the focus of the market.

The advantages of carbon steel sheet laser cutting machine for cutting carbon steel plate:

1. Good cutting quality

The cutting quality is good, the slit is small, the deformation is small, the cutting surface is smooth, flat and beautiful, and no follow-up processing is required.

2. Fast cutting speed

Continuous, fast curve cutting function and shortest processing path optimization function, greatly improve work efficiency;

3. High stability

The output power of the equipment is stable, the service life of the laser is long, and the maintenance is simple;

4. Powerful software

Various graphics and texts can be freely designed for real-time processing, flexible work, high efficiency, simple and convenient mechanical operation.

At present, the thin plate laser cutting machine mainly uses dry carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, brewed washed sheet, galvanized sheet and other metal materials for rapid cutting. I believe that in the future, there will be greater some action. The above is the whole content of the advantages of thin plate

fiber laser cutting machine for cutting carbon steel plate. I hope this article can be helpful to everyone.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

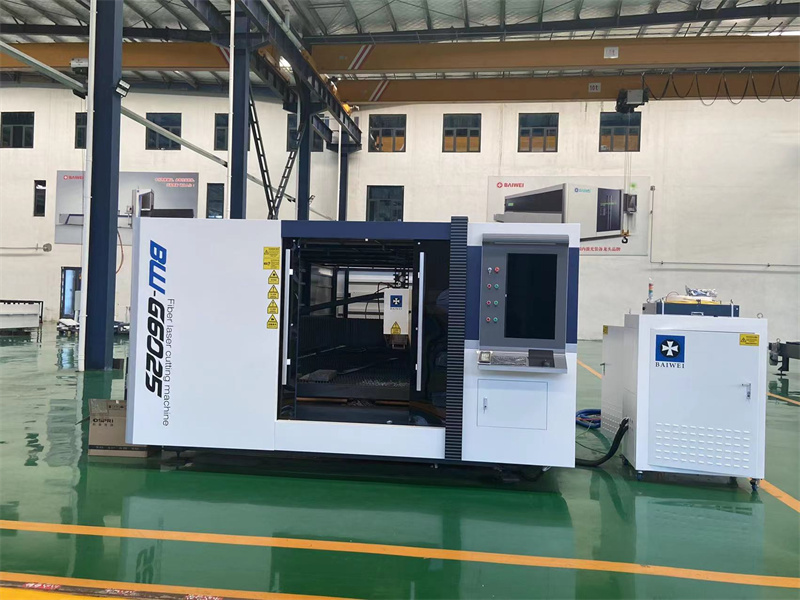

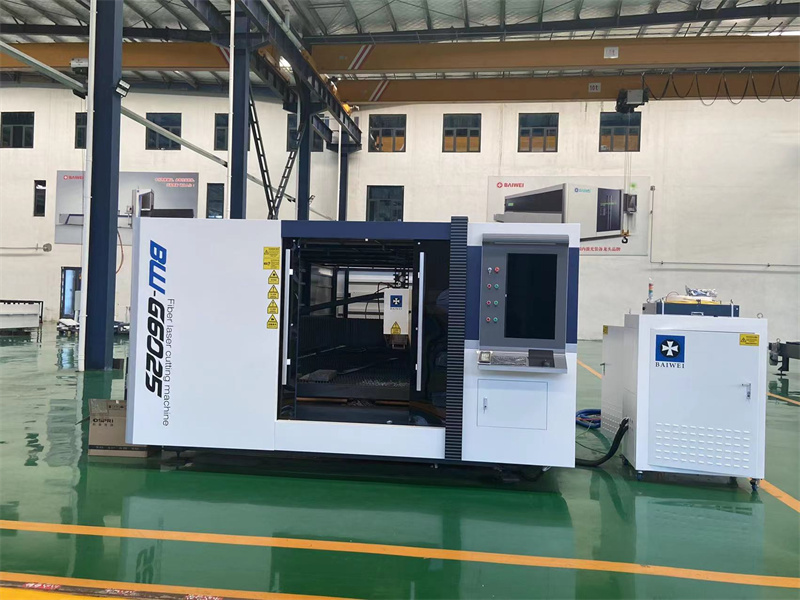

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)