What should I do if

the fiber laser cutting machine has poor cutting effect on carbon steel? Let me tell you. Carbon steel is a relatively common material in sheet metal processing. When carbon steel laser cutting machine is processing carbon steel plate, occasionally the cutting quality is very poor. Then, when the cutting effect of carbon steel laser cutting machine is very poor, we How to solve the problem?

According to the working and design principles of the laser cutting machine, it is concluded that the following reasons are the main reasons for the burrs of the workpieces:

1. The upper and lower positions of the laser focus are not correct, the focus position test needs to be done, and the adjustment is made according to the offset of the focus;

2. The output power of the laser is not enough. It is necessary to check whether the laser generator is working normally. If it is normal, observe whether the output value of the laser control button is correct and adjust it; speed;

3. The purity of the cutting gas is not enough, and it is necessary to provide high-quality cutting working gas;

4. If the laser focus is shifted, it is necessary to test the focus position and adjust it according to the offset of the focus;

5. If the machine tool runs for too long, the instability occurs, at this time, it needs to be shut down and restarted.

In addition, for the laser cutting machine processing of

carbon steel, there is another type of problem that occurs more frequently, that is, abnormal sparks occur during the processing of the fiber laser cutting machine, which will affect the quality of the cutting surface finish of the parts. .

At this time, when other parameters are normal, the following conditions should be considered: the loss of the nozzle of the laser head, the nozzle should be replaced in time. In the case of no new nozzle replacement, the cutting working gas pressure should be increased; the thread at the connection between the nozzle and the laser head is loose. At this time, the cutting should be suspended immediately, the connection status of the laser head should be checked, and the threads should be re-threaded.

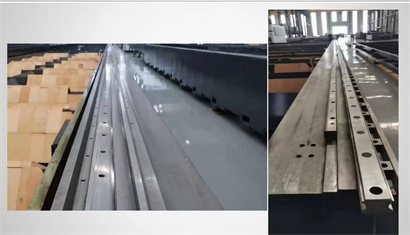

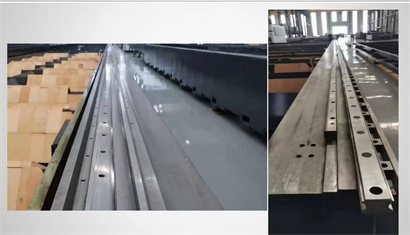

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)