In order to meet the needs of export and domestic continuous upgrading in the automobile manufacturing industry, the production of small batches and multiple varieties of vehicles has become the norm. The original GM body parts processing technology cannot fully meet the needs of current product quality and production. Among them, the laser cutting machine It has the characteristics of machining high-precision, porous and complex-shaped accessories, and has an irreplaceable role.

Now truck manufacturers have been equipped with CNC fine plasma cutting machines, laser cutting machines, etc., which are used for the processing of sheet metal parts with complex shapes and high precision requirements in automobiles. Laser cutting machines have been widely used in the automobile manufacturing industry and play an irreplaceable role in other CNC cutting equipment.

Its main advantages are as follows:

Applicable to a variety of material accessories

Automotive materials include low-carbon and low-alloy steel, high-strength steel, atmospheric corrosion-resistant steel, ferritic stainless steel, austenitic stainless steel and aluminum alloy, etc. All laser cutting equipment can process it, and its processing range can cover almost all materials in automobiles. pieces.

High machining accuracy

Laser cutting equipment has higher processing precision than other cutting equipment, and can meet the processing requirements of high-precision accessories.

narrow slit width

Small slits are beneficial to reduce the spacing between pipe fittings, improve material utilization, and reduce cutting slag generated during cutting.

High utilization rate of materials

When cutting accessories, you can cut different accessories with the same thickness and material, and make full use of the leftovers of the raw materials.

.png)

Low cut roughness value

Laser cutting equipment, when cutting accessories of the same material, has a lower cutting roughness value than other equipment. In the automobile manufacturing industry, the cross-section roughness of workpieces processed by different CNC cutting equipment is significantly different, and the cross-section roughness value of laser cutting is low.

Title HAZ Small

During the laser cutting process, the edge of the material to be cut will generate a heat-affected zone due to heat. However, compared to other machining methods, laser cutting has less concentrated heat input. Compared with fine plasma cutting and flame cutting, the heat-affected area is relatively small and the heat input is small, which is of great significance for ferritic stainless steels that are prone to grain growth by heating and high-strength steels that are easy to harden. Improve welding quality.

Low-cost laser cutting for small batch production

In mass production, the blanking die process is used for processing. In mass production, the cost of the die is evenly distributed to each part, and the production cost is low. However, if it is a small batch production, the punching die processing technology is used, not only the die production cycle is long, and the timeliness of parts processing cannot be met, but the die production cost is evenly distributed to each part, and the processing cost is relatively high.

Therefore, CNC cutting is generally used for processing. When using CNC plasma cutting for fine cutting, due to the weak perforation ability of plasma cutting, low cutting precision and poor hole quality, a drilling process needs to be added, and a drilling mold needs to be made. Not only the processing time is longer, but the cost is also higher. Laser cutting can ensure that parts are formed at one time, which is conducive to improving the timeliness of parts processing, and is suitable for small batch production. How to choose the cutting process needs to be comprehensively considered according to the size, shape, cost and accuracy requirements of the accessories. When the size of the accessories is small and the shape size and positioning size of the holes are required to be high, it is more economical to use the laser cutting method.

With the changes in the automobile manufacturing industry and the integration of the global economy, various automobile manufacturing enterprises have transformed from the original single, large-scale national railway car production to small-scale, multi-variety export vehicles. This transformation has also brought revolutionary changes to the manufacture of auto parts. The original sheet metal processing equipment such as shearing machines and punches are used less and less frequently. CNC fine plasma cutting machines, CNC flame cutting It has been replaced by CNC flexible equipment such as machine and laser cutting machine. Among them, laser cutting equipment has an irreplaceable role because of its advantages of processing high-precision, small-size, complex shape accessories, and being able to process a variety of materials.

.png)

Our client, Runzhibo Vehicle Industry Co., Ltd., is an Australian auto parts manufacturer with a factory located in Changzhou City, China's auto parts industry base. Its main business is the manufacture of automobile bumpers, lamps and mirror plastic parts. The product is suitable for Volkswagen series and Audi series models. Products are mainly sold to the Middle East, Taiwan, Southeast Asia, South America, Europe and other countries.

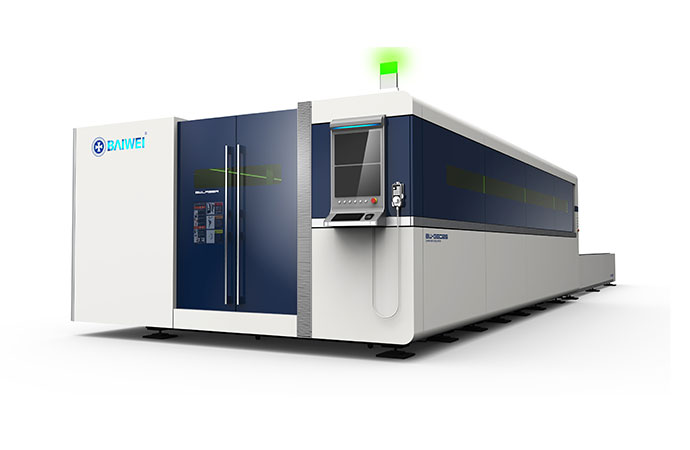

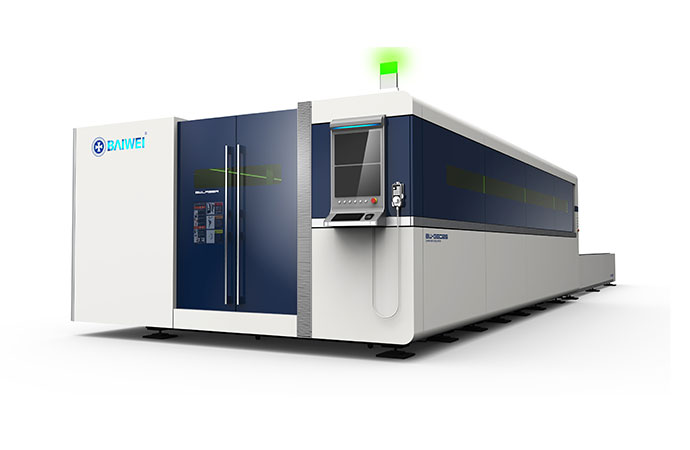

After communicating with the company many times, at the end of 2021, Zhibo Vehicle Industry Co., Ltd. introduced a 3000K open laser cutting machine equipment from Baiwei Laser. The general manager of the company's purchasing department said in the conversation that when considering buying equipment , the company is in the stage of production scale expansion. After a full understanding, the customer decided to invest in our equipment. The reason why they choose us is because they believe in the brand and quality of Baiwei. In recent years, Baiwei Laser has developed rapidly and continuously expanded its business at home and abroad. More and more customers at home and abroad choose Baiwei Laser.

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)

.png)

.png)