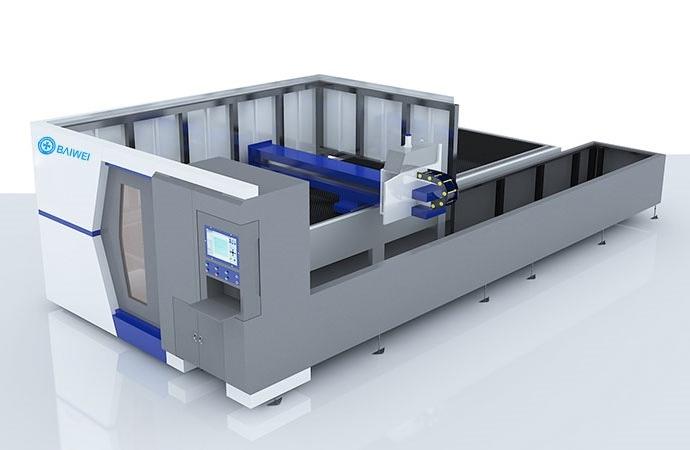

What’s the most important thing you need to consider when choose fiber laser cutting machine?

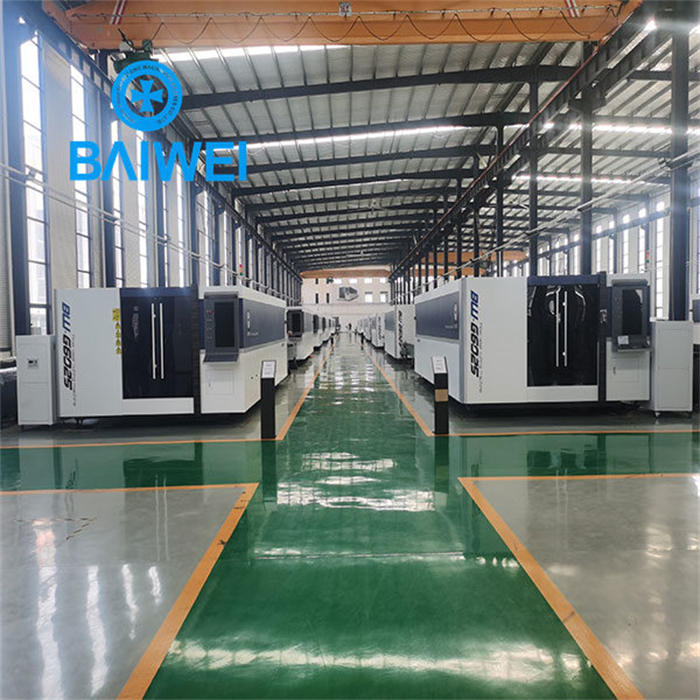

Baiwei high quality fiber laser cutting machine is the top brand in this industry. We special insist produce machine table in our factory, so we can make sure each step is under our strict quality control.

Main configuration of our machine:

1. 2kw&3kw&4kw&6kw&8kw&10kw Raycus laser source;

2.BM111 Swiss Raytools laser cutting head with auto focus;

3.Japan Panasonic servo motor

4.Taiwan YYC Precision gear rack

5.Japan NSK bearings

6.French Schneider electrical parts

7.Japan SMC Pneumatic components

8.Japan Shimpo reducer

9.Taiwan HIWIN square rail

10.CypCut 2000 CNC Control System

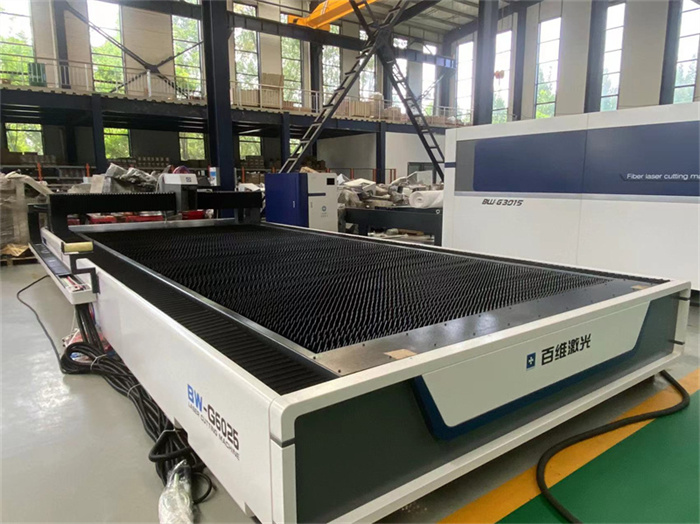

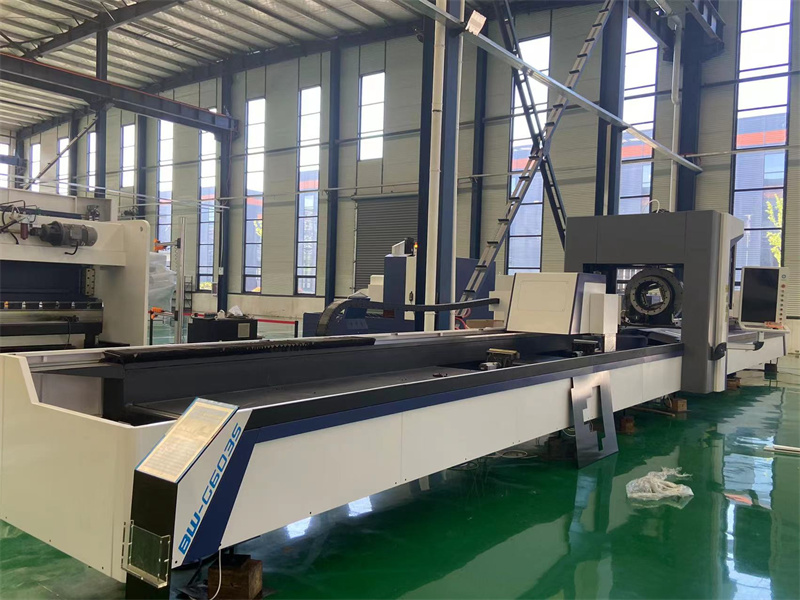

11.Baiwei heavy plate welding bed after heat treatment

What’s the most important factor you consider when choose high quality fiber laser cutting machine?

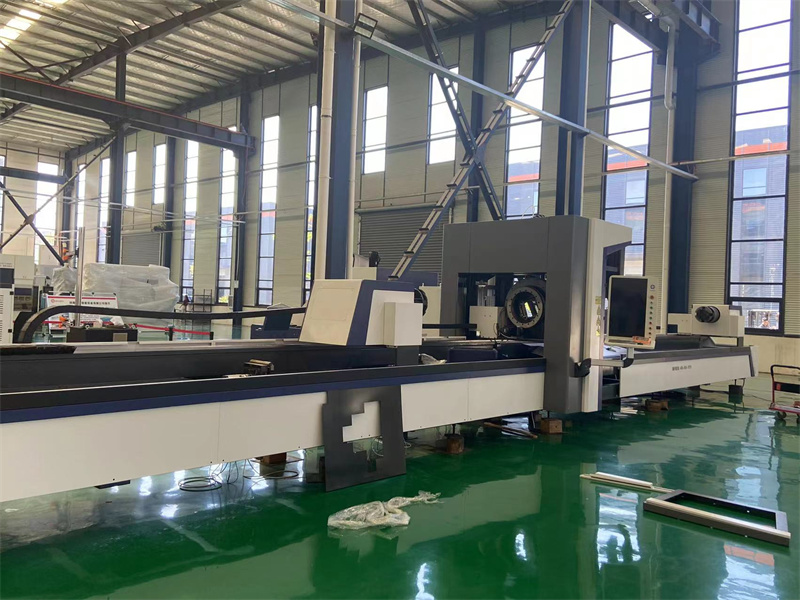

As we all know, thousands of spare parts make up of fiber laser cutting machine, but there are two important factors effect quality and precision. One is laser source, the other is machine bed. Based on same quality laser source, only machine bed is a key factor to effect quality. You must have experience to buy car before, a good engine must match a good chassis.

Here is the reason why choose us:

1. Real manufacturer ;

we have complete production line to process machine bed; From select raw materials, welding, painting, processing, debugging etc.

All these process are done in our factory, so we can control the quality of each step.

We also do OEM and ODM services for world famous laser brand.

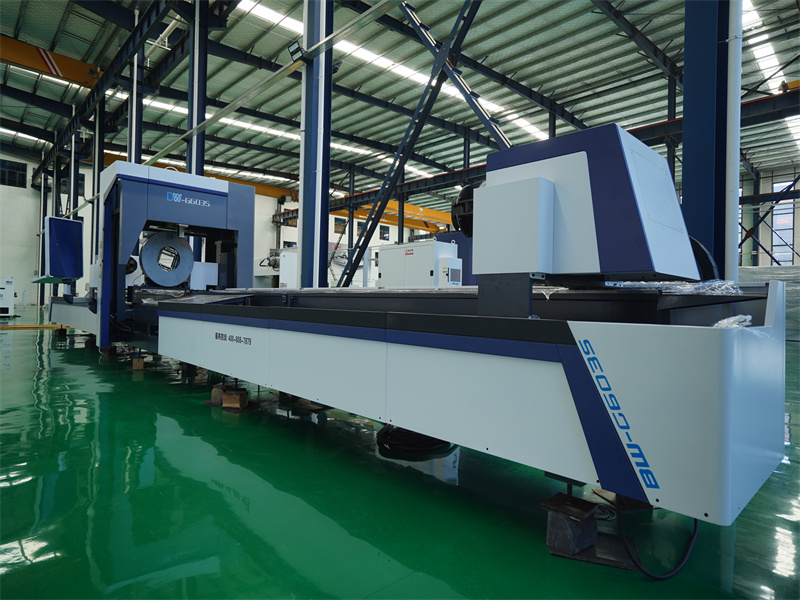

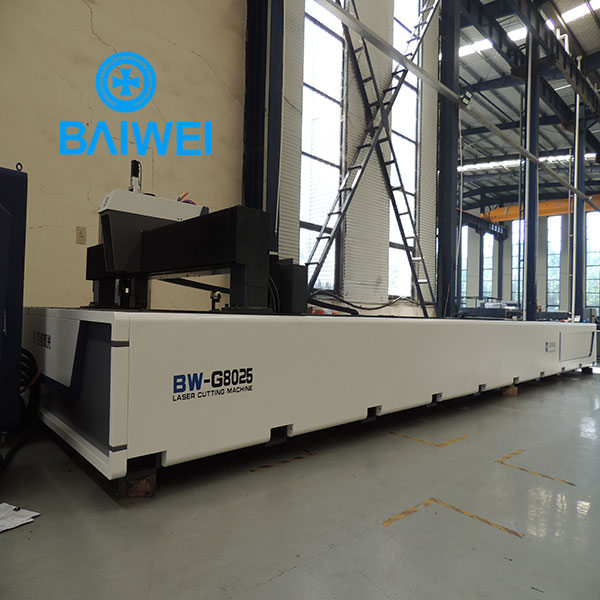

2. Heavy machine bed;

Heavy machine bed weight to ensure it’s rigidity, stable and durable;

3. 20 years using time;

the complete machine frame go through the heat treatment, release the gravitational force,ensure 20 years using time;

4. High precision within 0.01mm;

a.with Value 8.5 Million USD Ten CNC Gantry Equipment to process our machine table and gantry beam;

b.with Renishaw Laser Interformeter to debugging our machine table’s precision after assembly.