What kind of gas does the fiber laser cutting machine need?

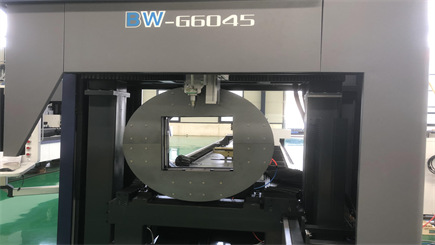

What kind of gas does the fiber laser cutting machine use when cutting the metal sheets? Fiber laser cutting machine is one of the laser cutting equipment, which utilizes light power to pierce the processing material. The basic operation principle is the photoelectric conversion, the laser generator is driven by the electronic power, and transport the optical fiber into the cutting head. After the metal sheet melt, the high pressure gas will blow it away, then the cutting is finished. How to select the gas? It depends on what kind of metal sheets you want to cut. Normally, if cut mild steel / carbon steel, can choose Oxygen or Compressed air. If cut stainless steel, aluminum, copper, brass an so on, choose Nitrogen.

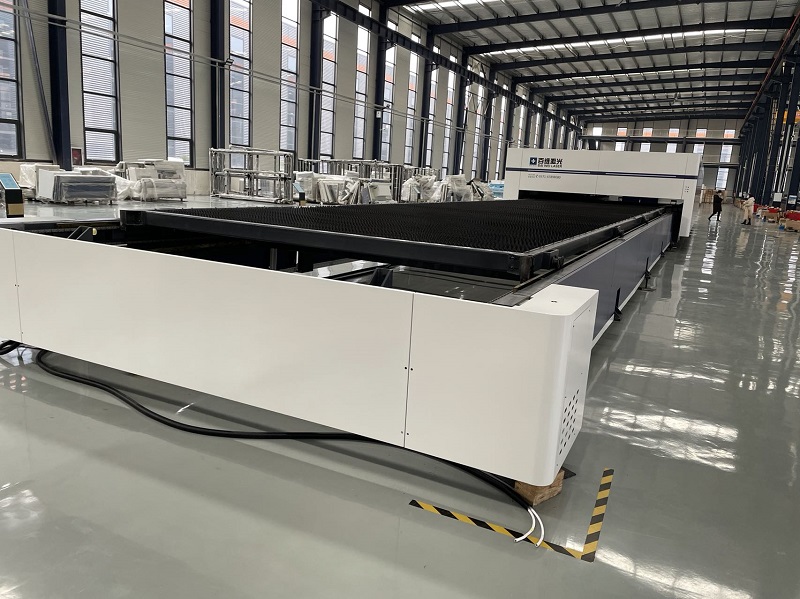

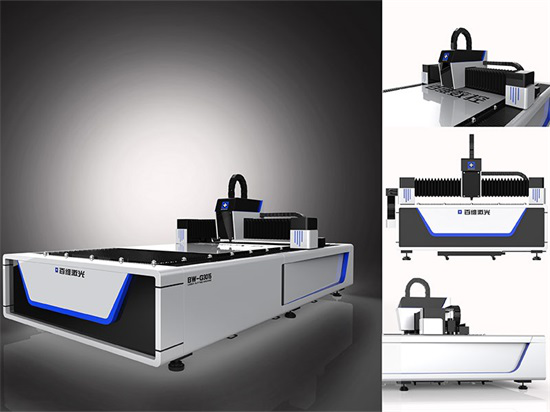

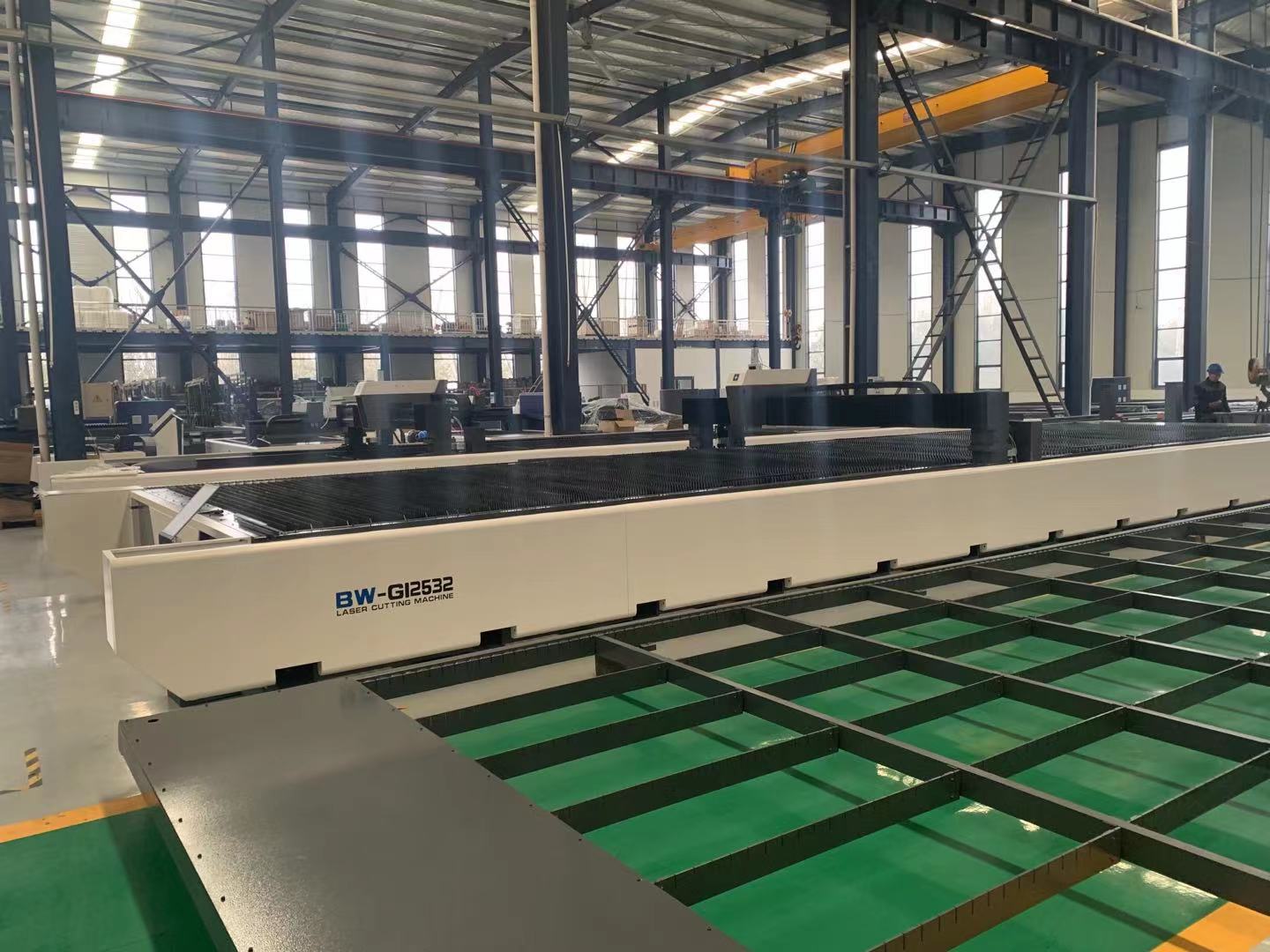

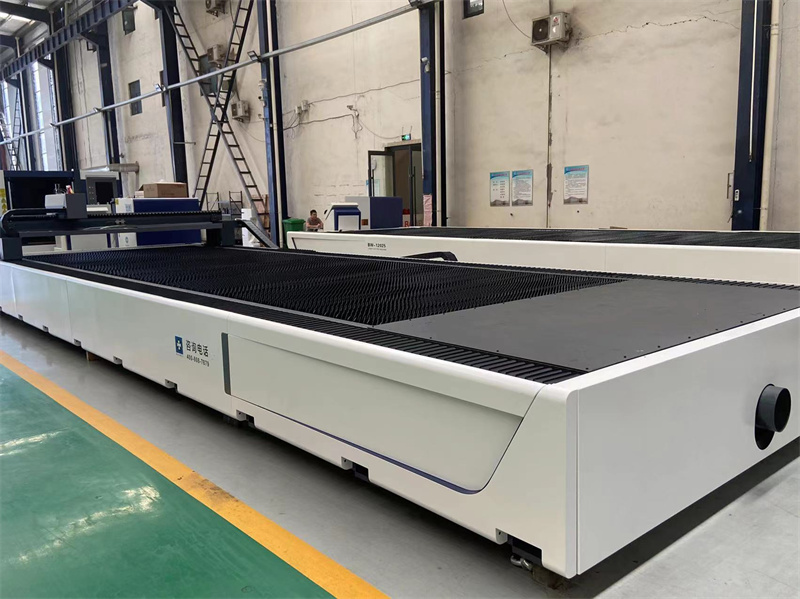

Model: BW-G6025-6kw

Power: 6000W

Laser source: IPG

Cutting Head: Raytools

Control system: Cypcut (China)

Servo motor : YASKAWA (Japan)

Reducer: Neugart

Gear and rack: YYC (Taiwan,China)

Guide rail : HIWIN (Taiwan,China)

Warranty time THREE YEARS

Working Area: 6000*2500mm

Cutting Thickness Max 30mm MS, Max 16mm SS

Fiber laser cutting machine is one of the laser cutting equipment, which utilizes light power to pierce the processing material. In comparison with normal light source, laser generator has its unique character, like great directionality, monochromaticity, coherence and energy concentration. Among these factors, monochromaticity depends on the frequency stability, while the best monochromaticity could be realized by the gas laser generator.