What gas is most commonly used in laser cutting machines?

Common auxiliary gases are: air, oxygen, nitrogen, oxygen for cutting carbon steel, and the purity is generally above 99.5%. The main function is to help burn and blow off the cut melt. And the pressure and flow of each laser cutting machine are different, which is closely related to the size of the cutting nozzle and the thickness of the cutting material. Generally, the required pressure is 0.3-0.8 MPa, and the cutting nozzle is generally 0.02-0.05 MPa. The flow rate varies according to the thickness of the cutting material.

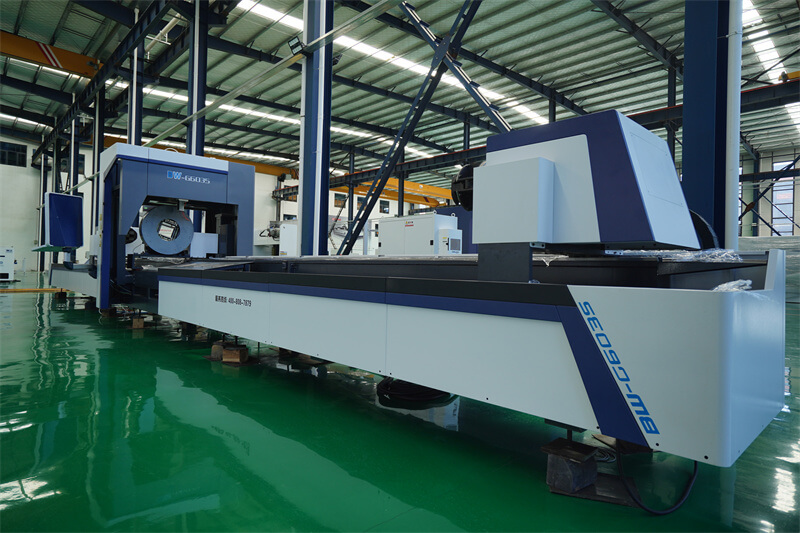

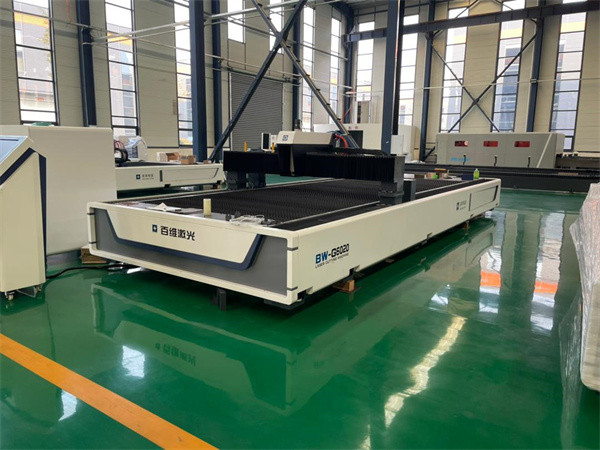

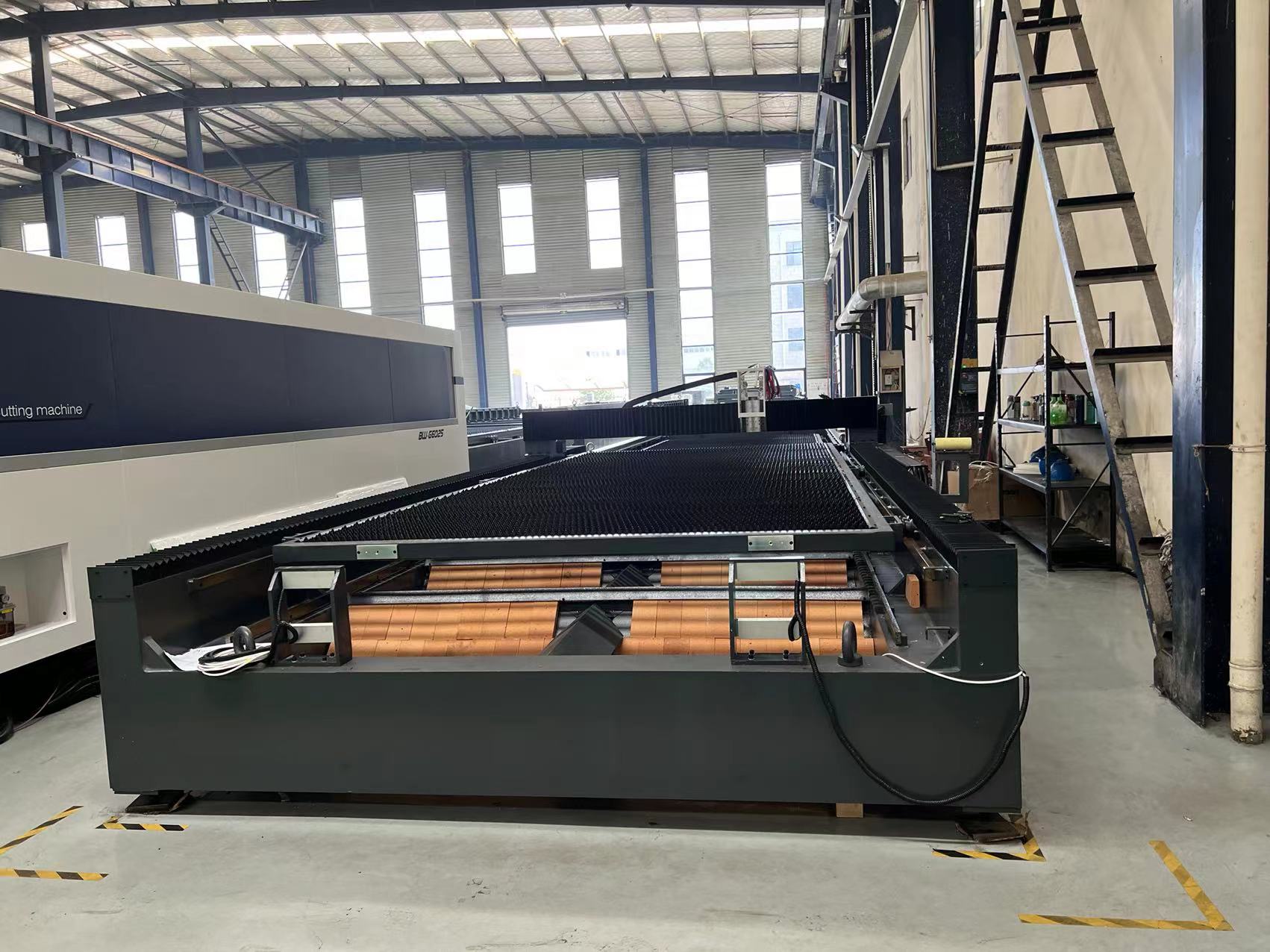

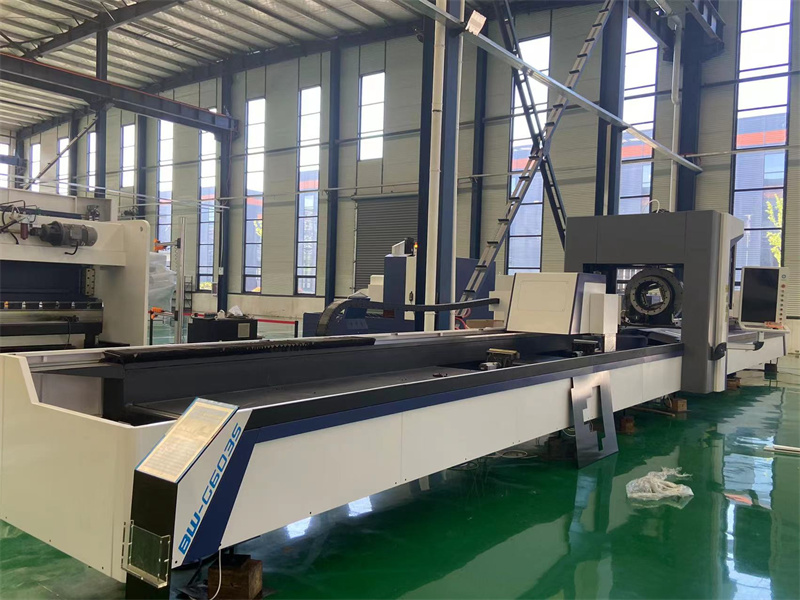

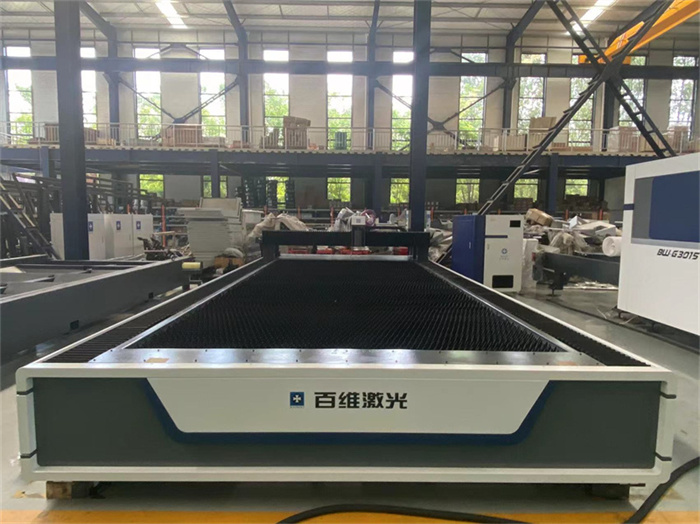

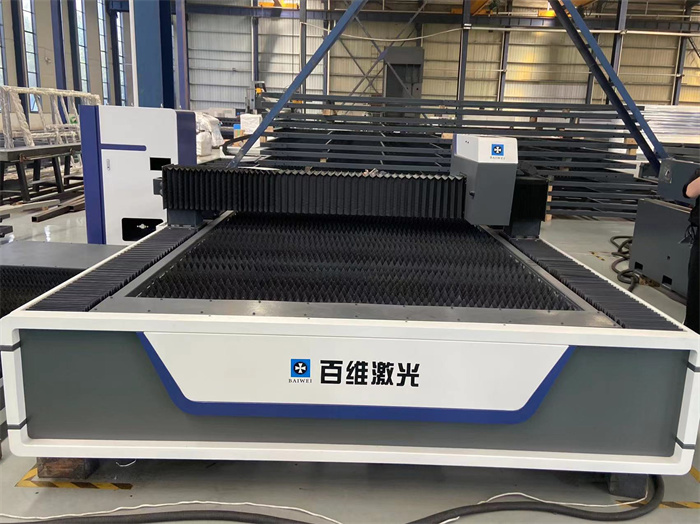

Name:Closed Type Fiber Laser Cutting Machine

Model:BW-G4020/BW-G6020

Cutting Range:2000*4000mm/2000*6000mm/According to demands

Laser Power:500w/1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw

Max.movimg Speed:100m/min

Max.cuttimg Speed:35-80m/min

Positioning accuracy:0.03mm

Re-position accuracy:0.02mm

Min.Line Width:0.1mm