What are the most important Advantages of Fiber Laser Cutting Machines?

All laser cutting processes have their own inherent advantages and disadvantages, but it appears that the benefits of fiber laser cutting machines far outweigh that of any of the other processes. It’s one of the newest forms of laser cutting, as it’s only picked up traction in the last couple decades or so. However, the benefits that fiber laser cutting machines provide, which we will discuss below, have been quickly realized by metal fabricators all over the country. Fiber laser cutting machines can easily and seamlessly adapt between industries for a huge range of applications. Continue reading to learn more about the other benefits of these powerful machines.

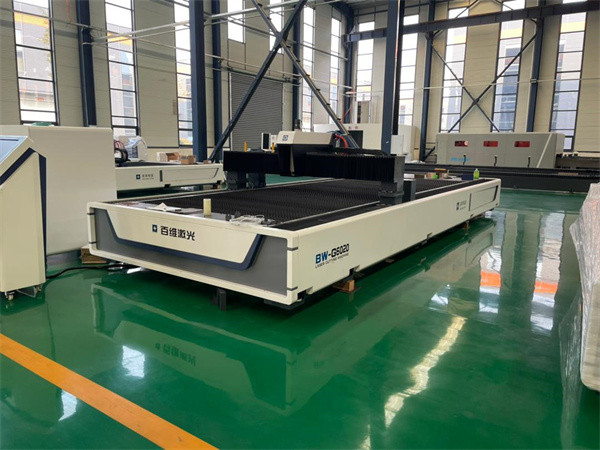

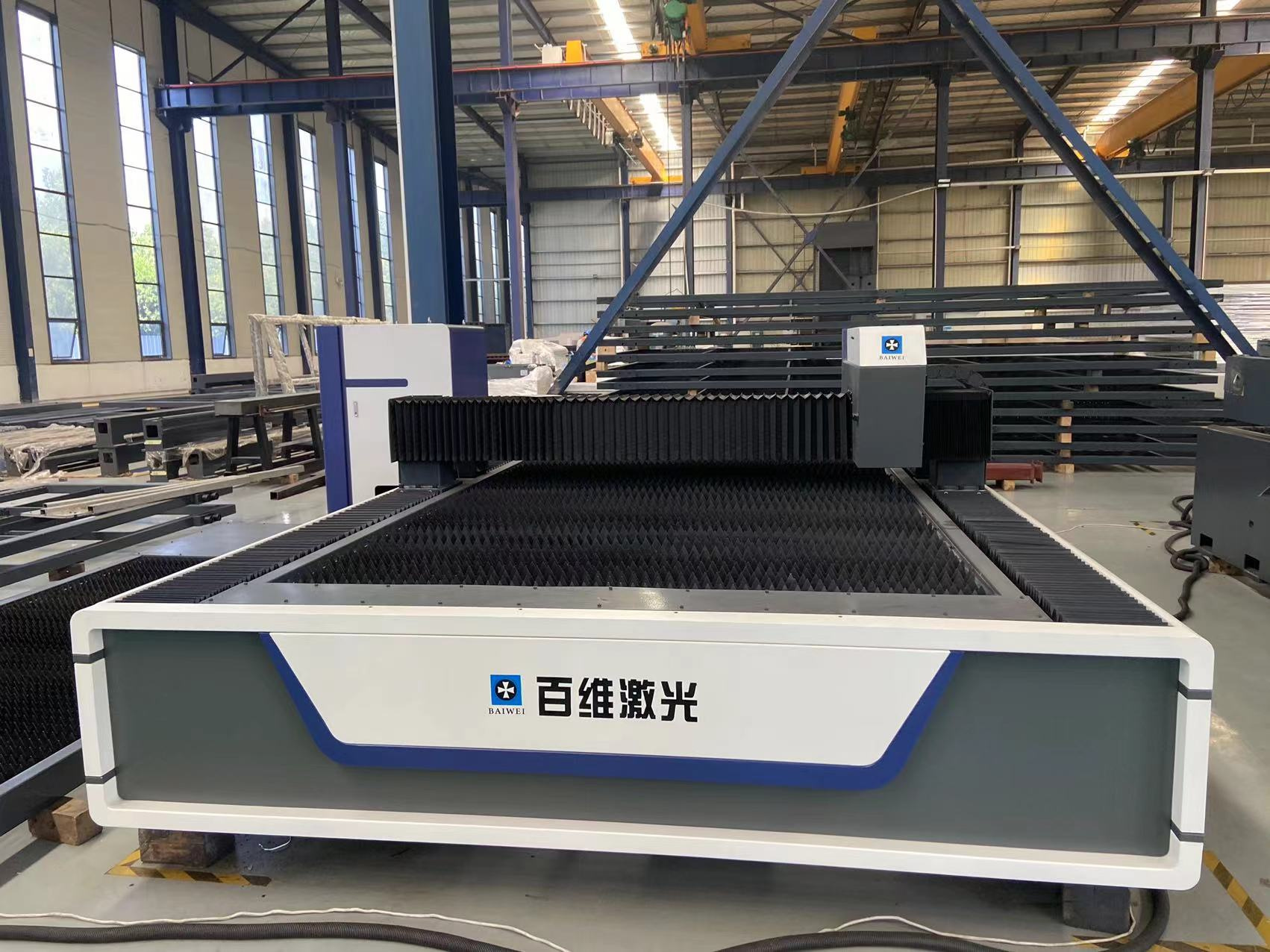

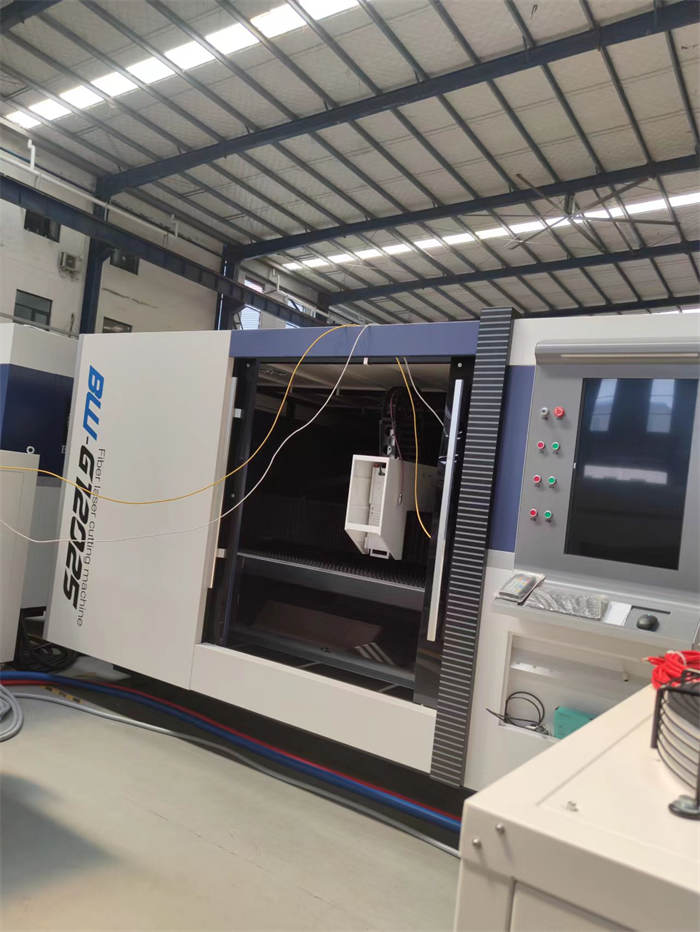

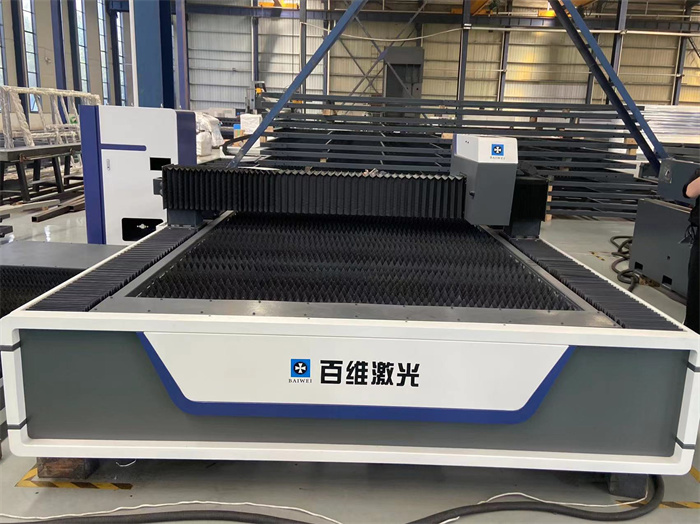

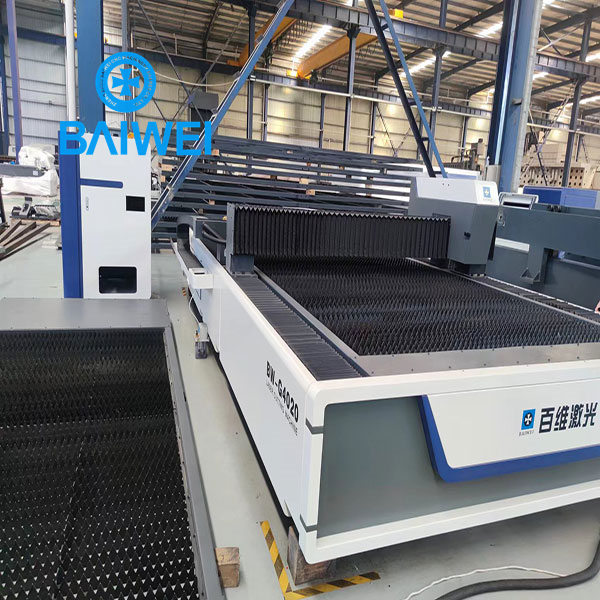

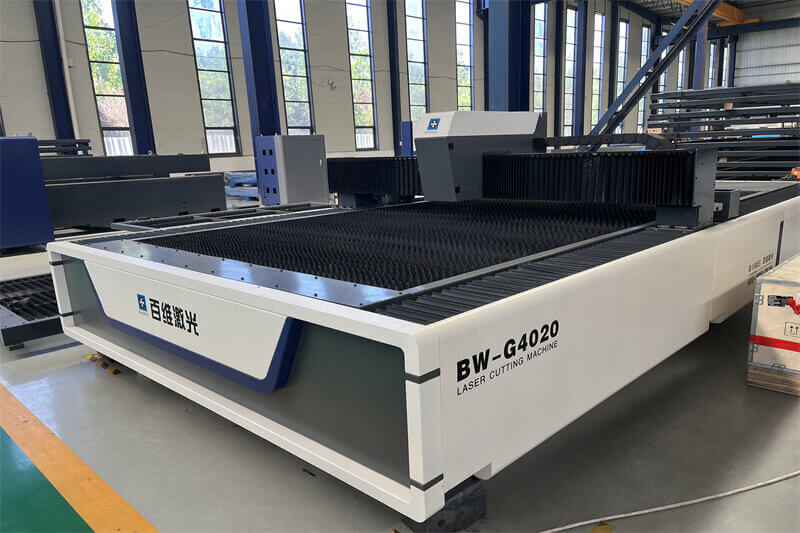

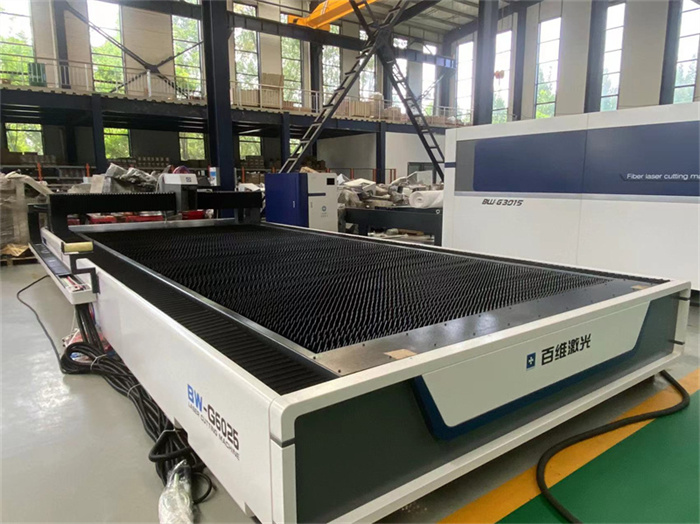

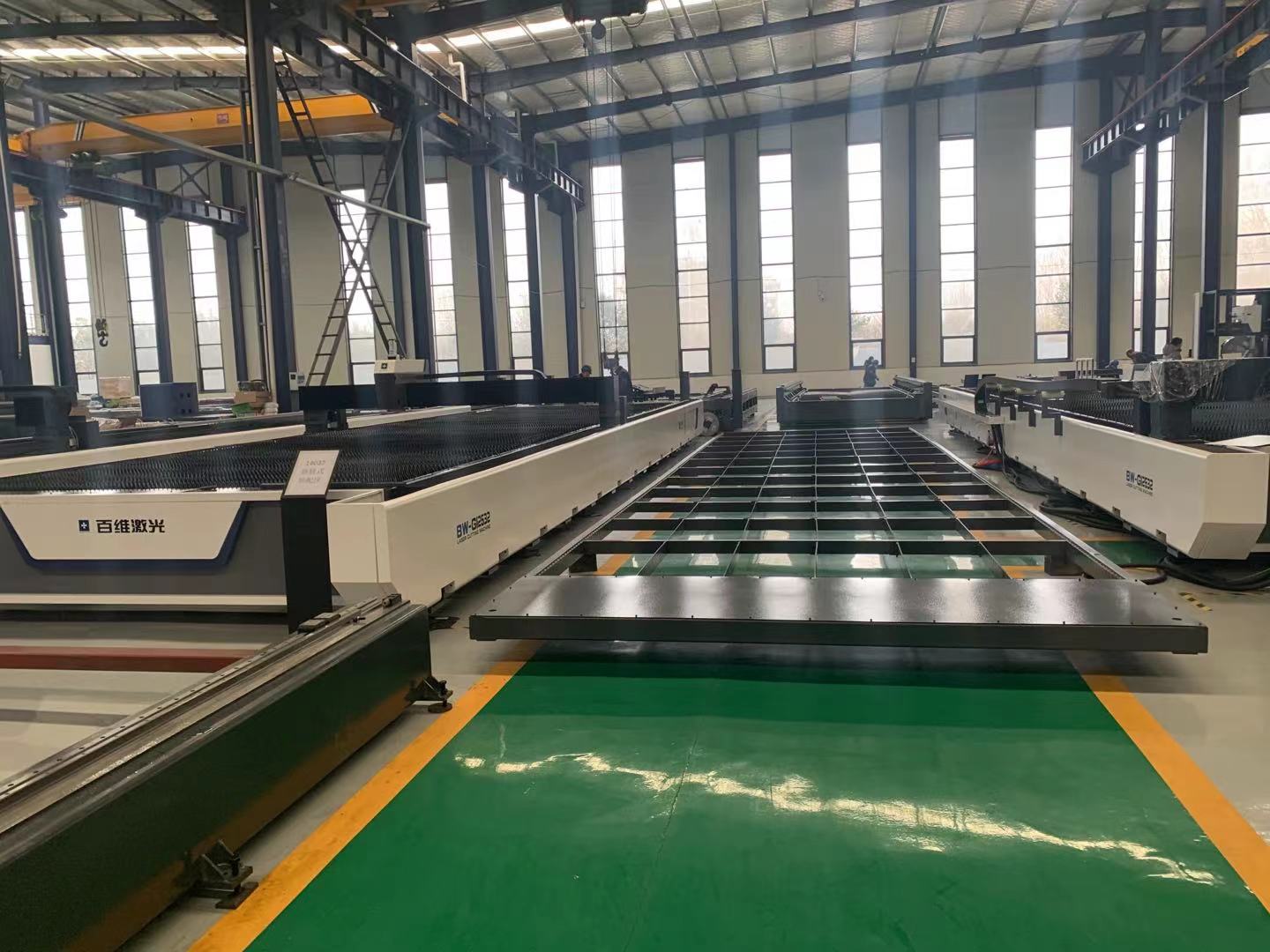

Characters of Baiwei fiber laser cutting machine

High capacity fiber lasers are made in the combination of two most creative and sophisticated laser technologies: effective optical fiber and semiconductor diodes. The lasers activate diode as the source of light to impel the active fiber. In the optical fiber, the laser ray is generated and then is relayed by flexible resistant wire. Quality active fibers and rare-earth ions are doped together facilitating high power generation of an extremely small core that efficiently produces powerful lasers of one kilowatt with superior beam quality.

What are the Benefits of Fiber Laser Cutting Machine?

Fiber lasers offer several primary advantages. The light propagating in the fibers is well shielded from the environment, and fiber lasers tend to be very compactly designed. They offer a large gain bandwidth, wide wavelength tuning ranges, and have the capacity to generate ultra-short pulses. Operating at high power with great efficiency, they are suitable for many types of cutting procedures.

Fiber lasers can cut through thin materials at very high speeds. They also have the ability to cut reflective materials without risk of reflections causing damage to the machine, which allows metals such as copper, brass and aluminum to be cut without issue.

Why Is It Beneficial to Use Parts Cut With a Fiber Laser?

The main reason to employ fiber laser cutting techniques is to reduce the mechanical stress that a sheet metal form experiences while being cut. Lasers help to eliminate the impact stress that can adversely affect sheet metal products during cutting, and beyond that, the heated zone is incredibly small. This means that the rest of the work piece is exposed to little or no heat, preserving the properties of the material being handled, which is incredibly important.

Also, it’s important to consider that since laser cuts can be made incredibly close to one another without negatively impacting the sheet metal, they help to minimize waste— closer cuts allow you to make more parts per square foot of sheet metal you use.