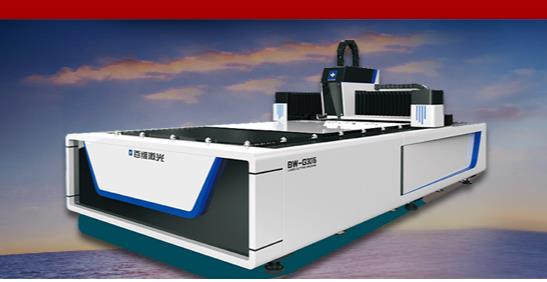

Tube Pipe Fiber Laser Cutting Machines 1000W 2000W 3000W 4000W 6000W Sheet Metal Laser Cutting

Parameter

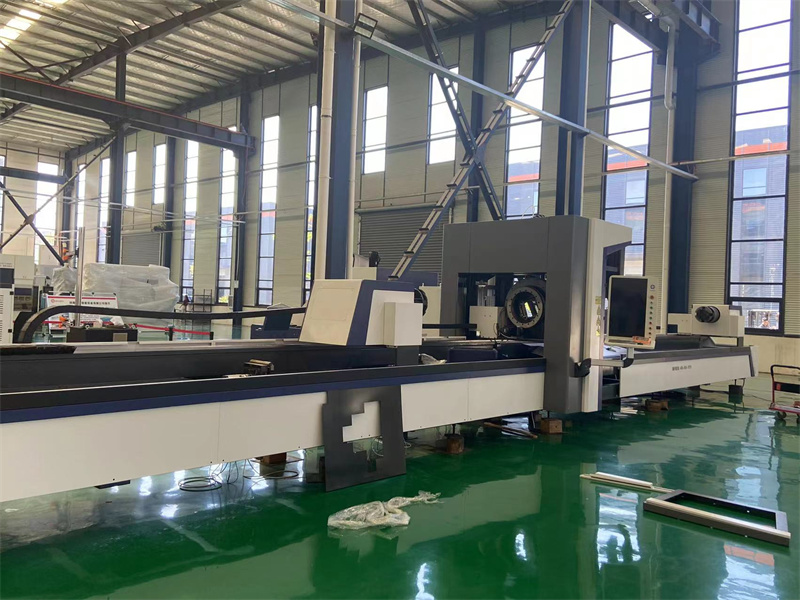

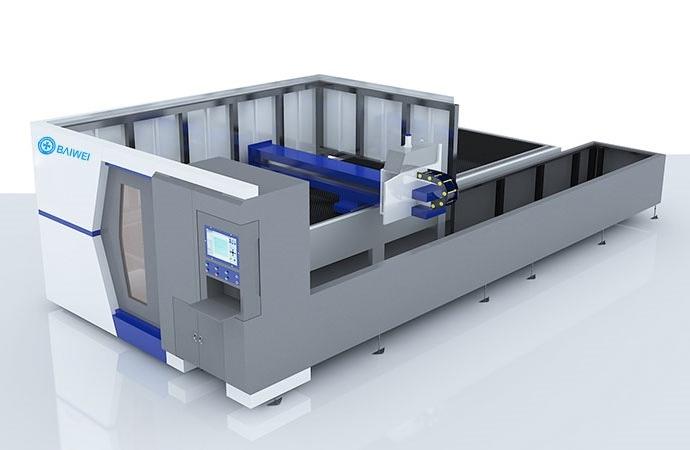

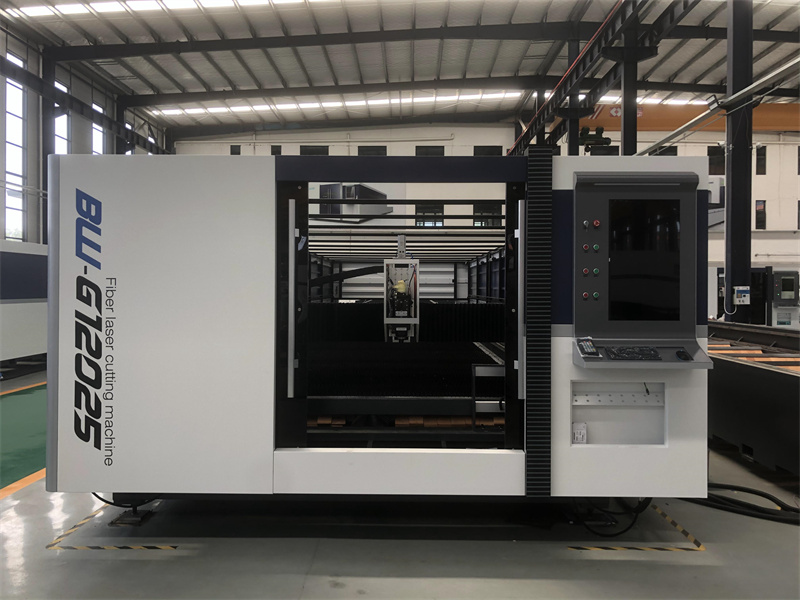

Model BW3000/BW6000/BW9000

Laser Generator Medium Fiber Laser Source

Output Power 3000W/4000W/6000W/8000W/12000W

Effective pipe cutting diameter 15-220mm

Working axial positioning accuracy <±0.05mm

Worktable reposition accuracy <±0.02mm

The laser cutting machine is to focus the laser light emitted from the laser into a laser with high power density through the optical path system.

beam. The laser beam is irradiated on the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam will melt or vaporize

The metal is blown away to create the cut.

With the movement of the relative position of the beam and the workpiece, the material is finally formed into a slit, so as to achieve the purpose of cutting.

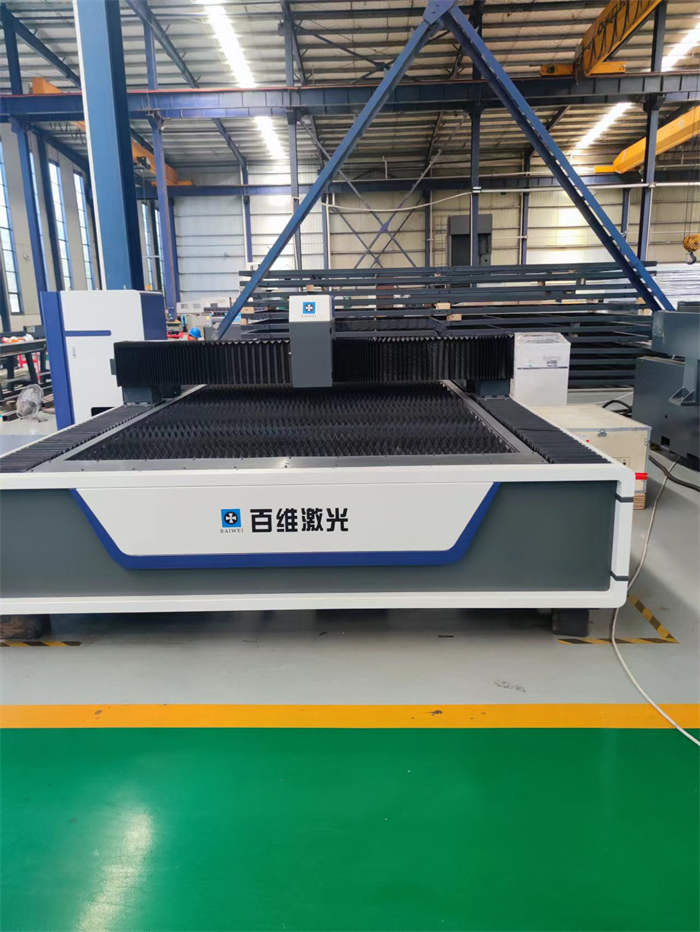

Laser cutting replaces traditional mechanical knives with invisible beams, with high precision, fast cutting, and not limited to cutting diagrams.

Case limitation, automatic typesetting to save material, smooth incision, low processing cost, etc., will gradually improve or replace the traditional metal cutting process equipment.

The mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the surface of the workpiece during work; the laser cutting speed is fast and the incision is smooth.

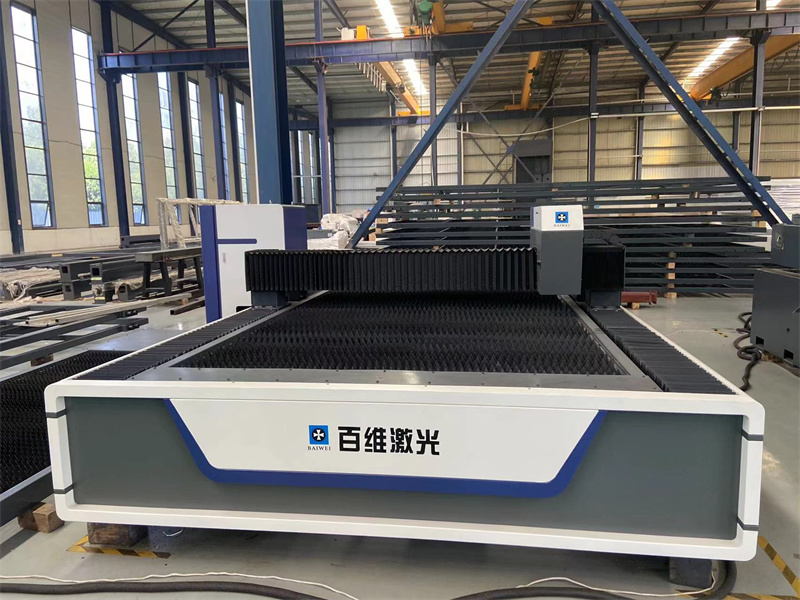

Smooth and flat, generally no follow-up processing; small heat-affected zone for cutting, small plate deformation, narrow slit (0.1mm~0.3mm); no machine cut

Mechanical stress, no shear burr; high machining accuracy, good repeatability, no damage to the material surface; CNC programming, can process any plane

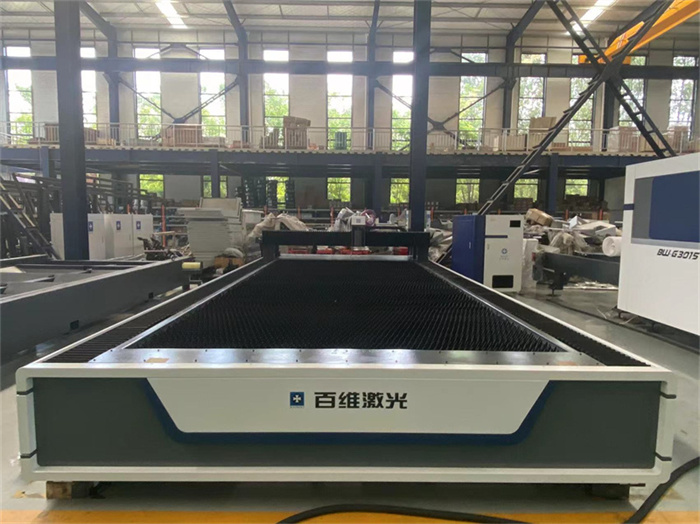

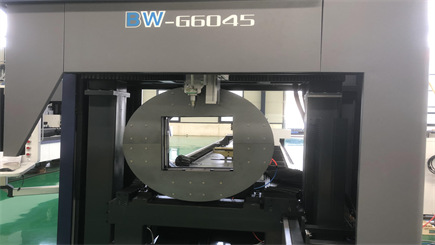

As shown in the figure, it can cut the whole board with a large format without opening the mold, which is economical and time-saving.