The principle and advantages of laser pipe cutting machine

Parameter

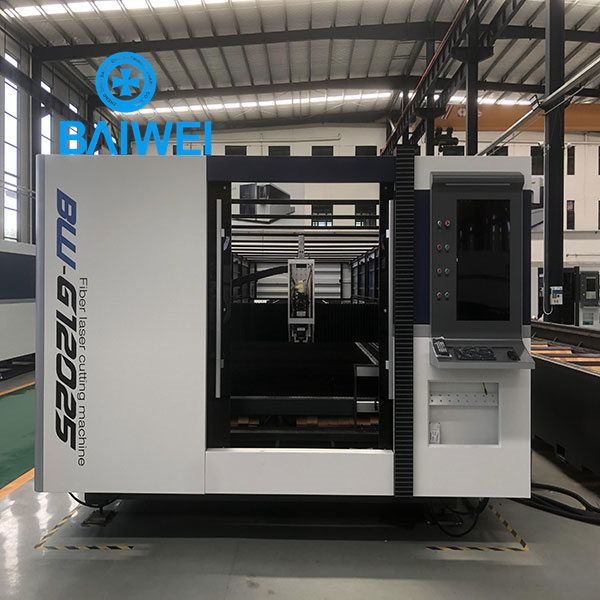

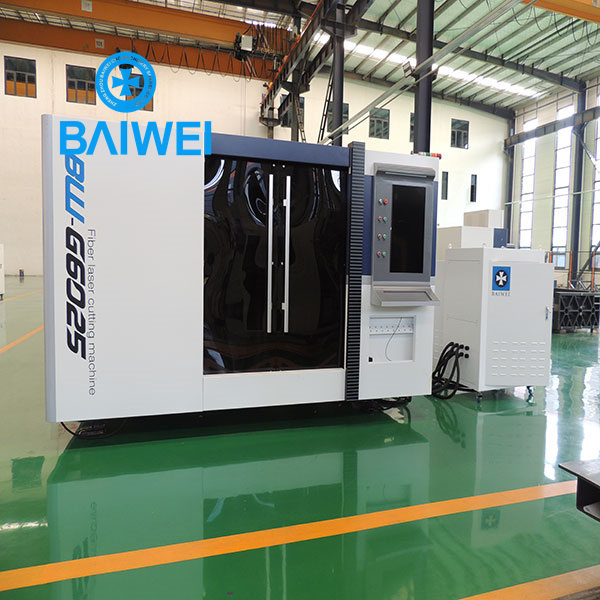

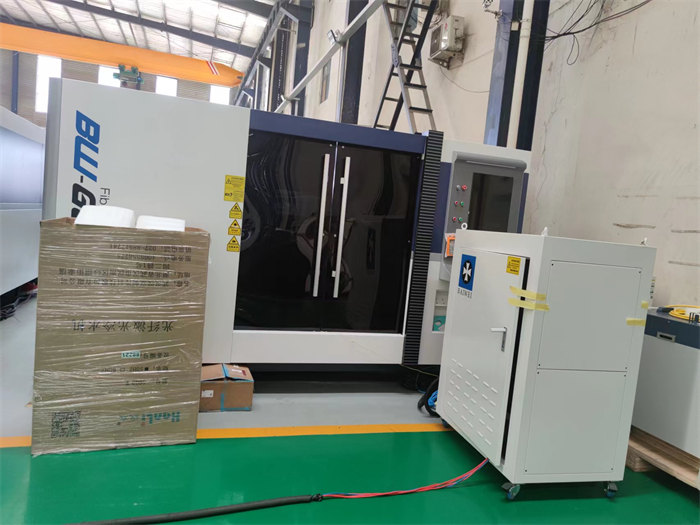

Model BW3000/BW6000/BW9000

Laser Generator Medium Fiber Laser Source

Output Power 3000W/4000W/6000W/8000W/12000W

Effective pipe cutting diameter 15-220mm

Working axial positioning accuracy <±0.05mm

Worktable reposition accuracy <±0.02mm

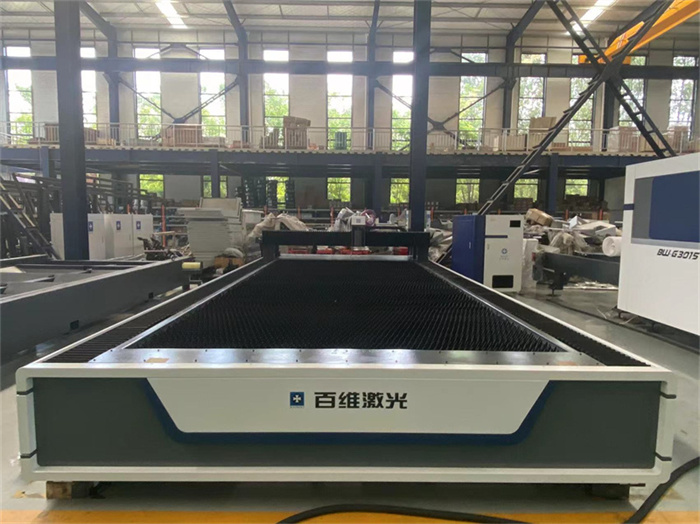

Principle of laser pipe cutting machine

The main working principle of the laser pipe cutting machine is to use the laser beam emitted by the laser to generate heat energy, and to cooperate with the moving mechanical system to realize the pipe cutting. The intelligent system controls the pipe cutting, which can improve the production efficiency.

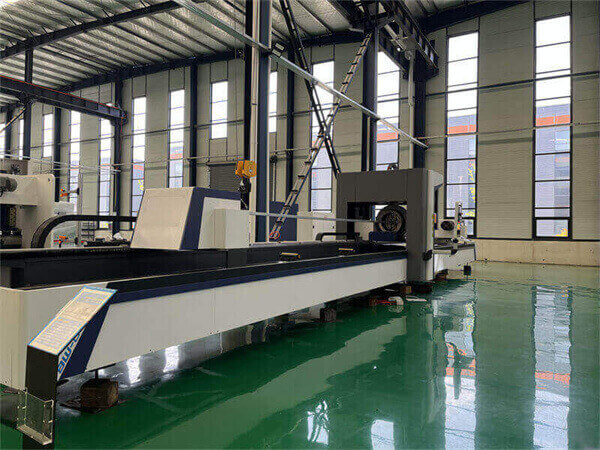

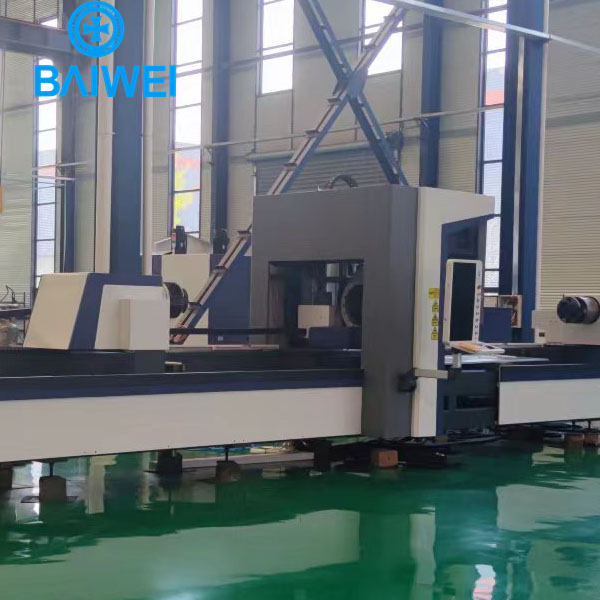

Laser Tube Cutting Machine Type

Laser pipe cutting machines mainly include: three-chuck laser pipe cutting machine, automatic laser pipe cutting machine, semi-automatic laser pipe cutting machine, manual laser pipe cutting machine, etc.

These laser pipe cutting machines can cut square, square, round, I-shaped pipes and special-shaped pipes made of stainless steel pipes, carbon steel pipes, iron pipes, seamless pipes, galvanized pipes and other metal materials, which can realize cutting, beveling, Various pipeline processing techniques such as hole opening and 45-degree bevel cutting