The difference between fiber laser cutting machine and traditional laser cutting machine

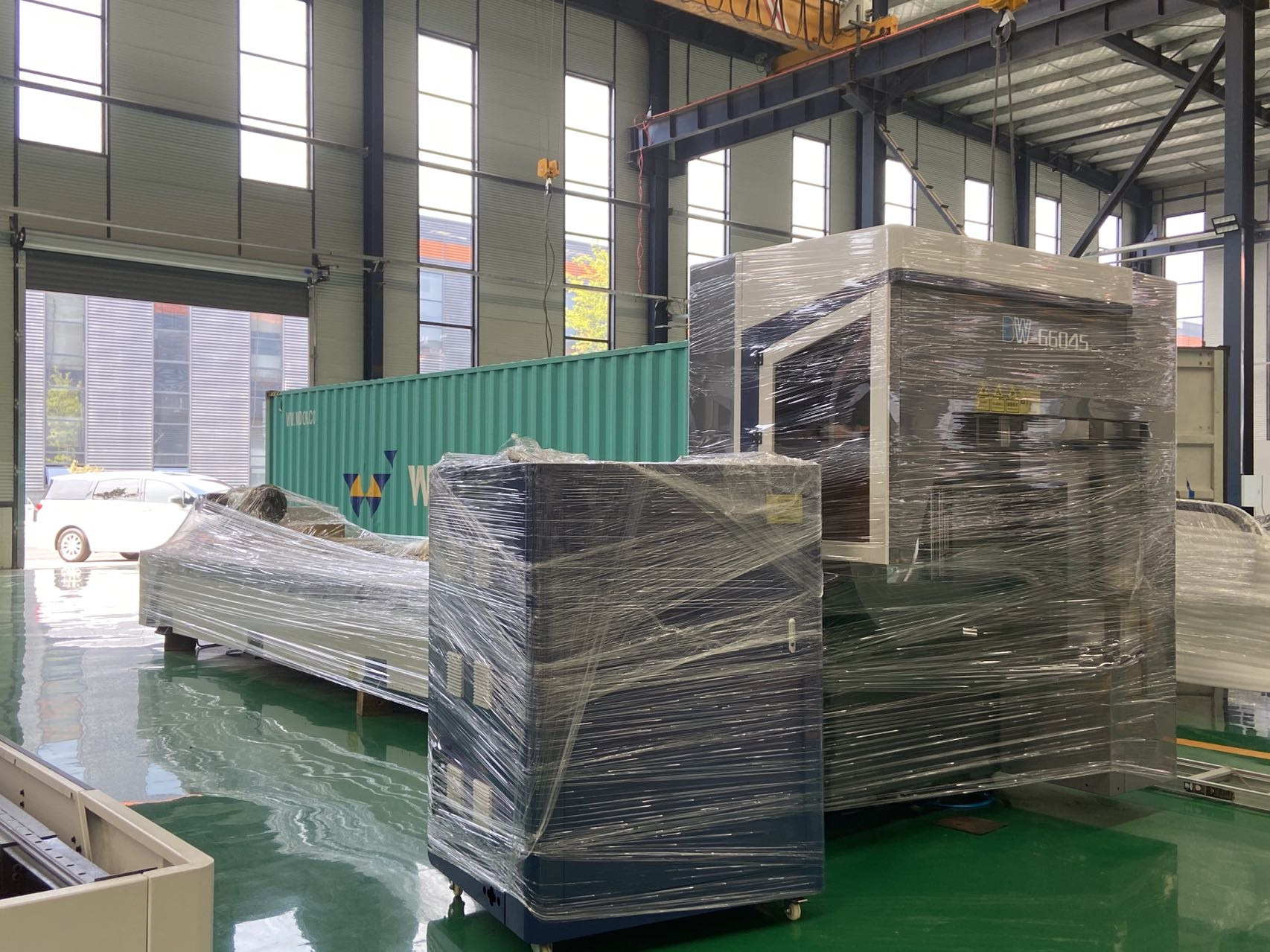

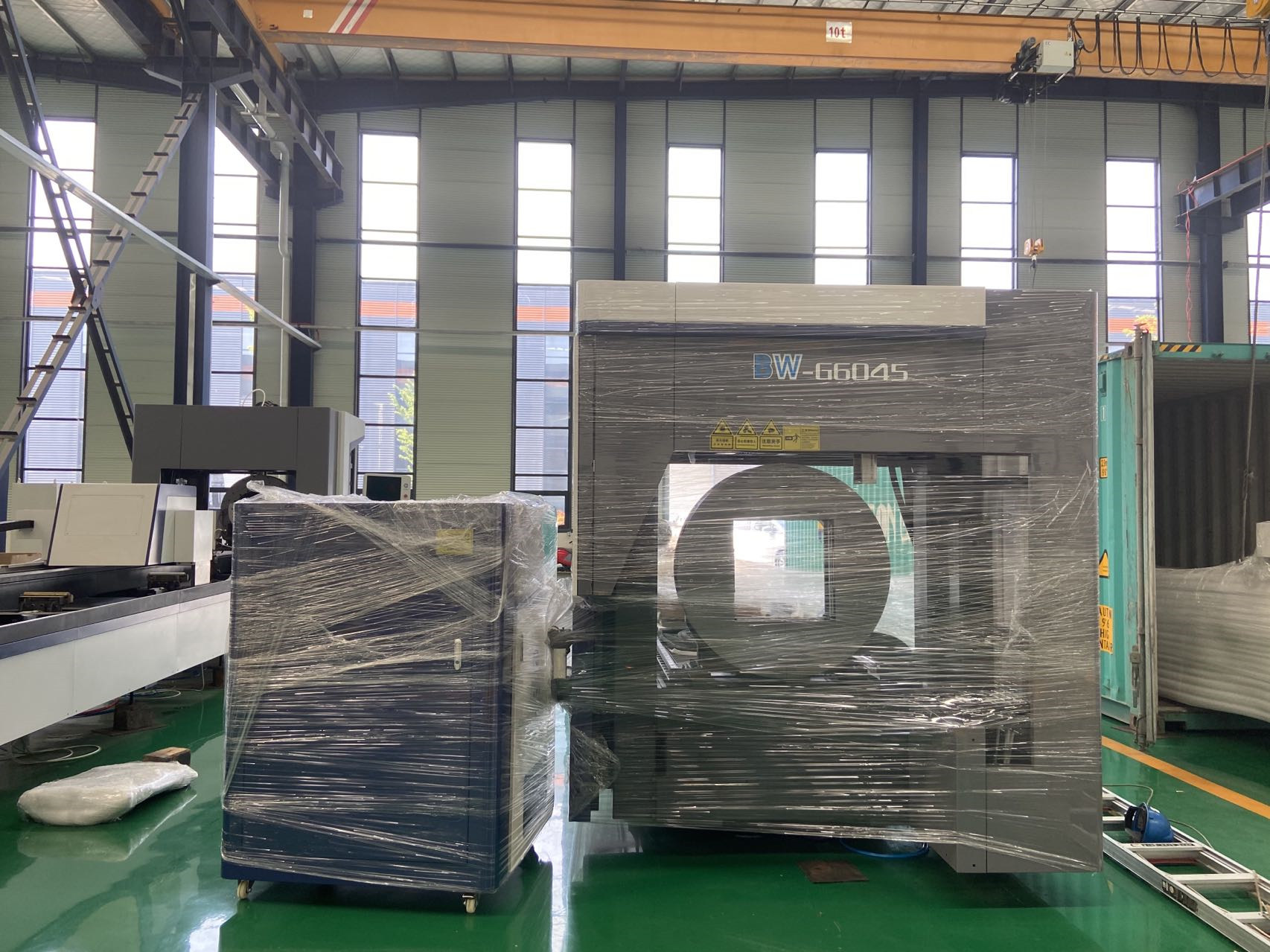

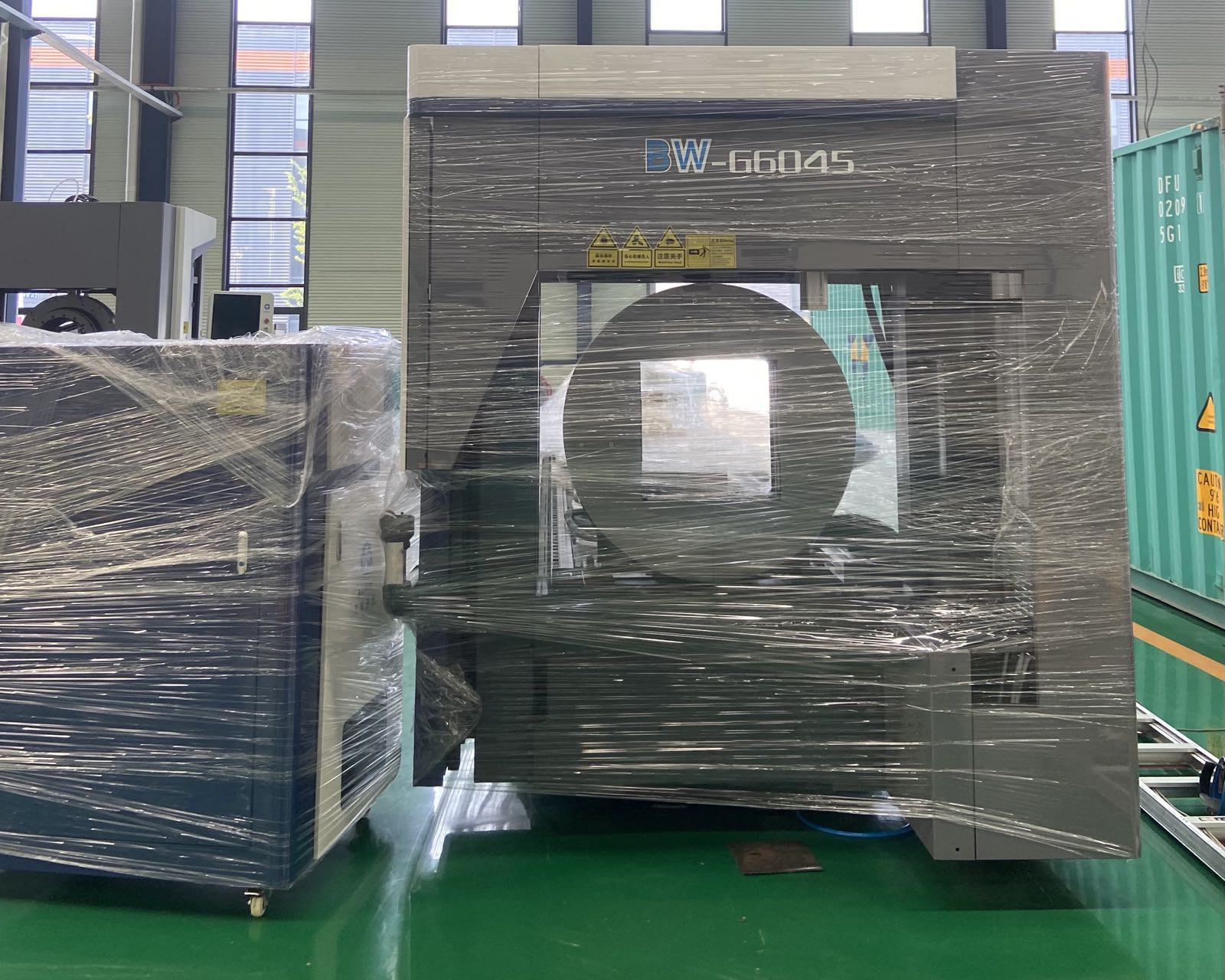

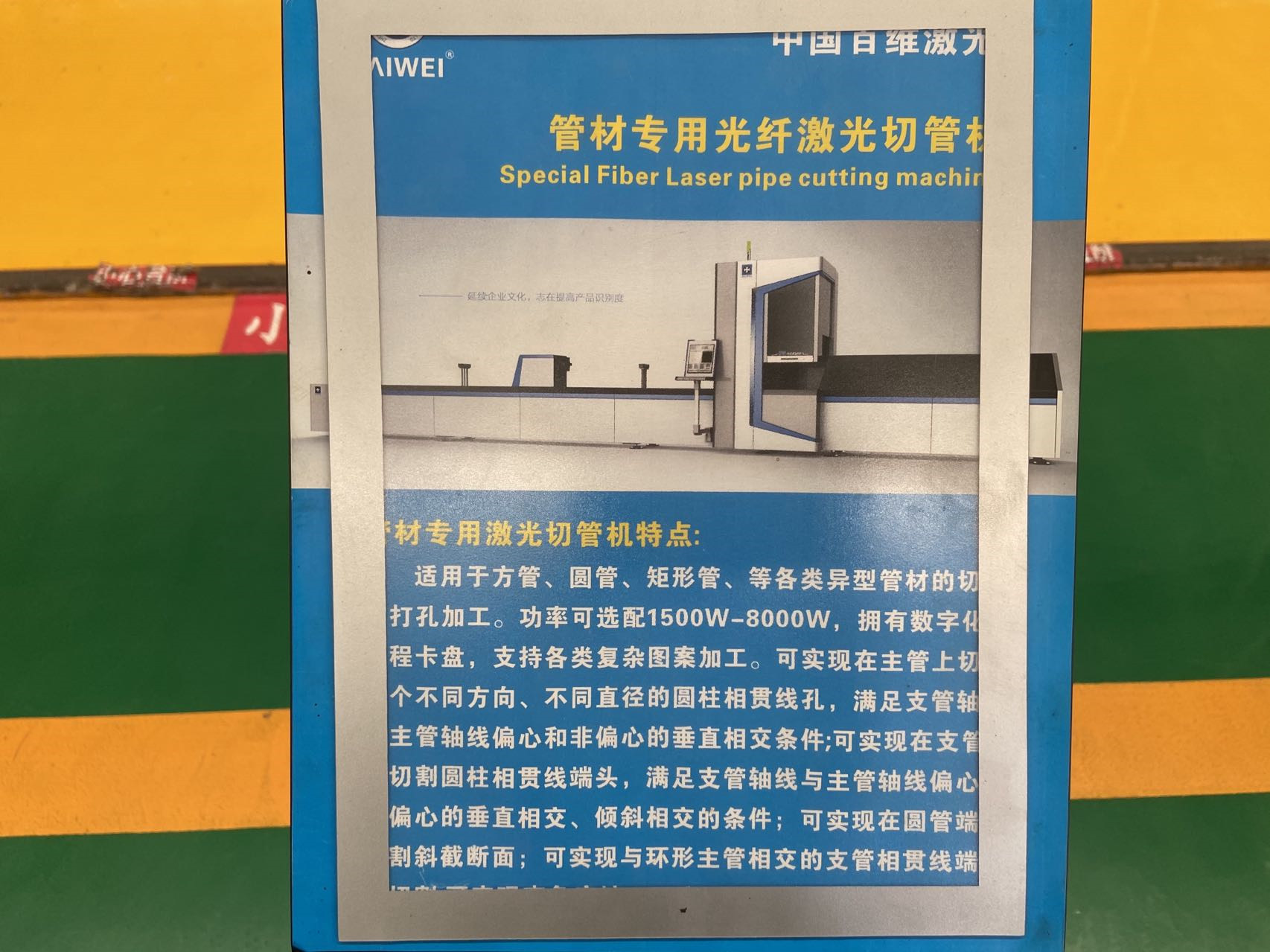

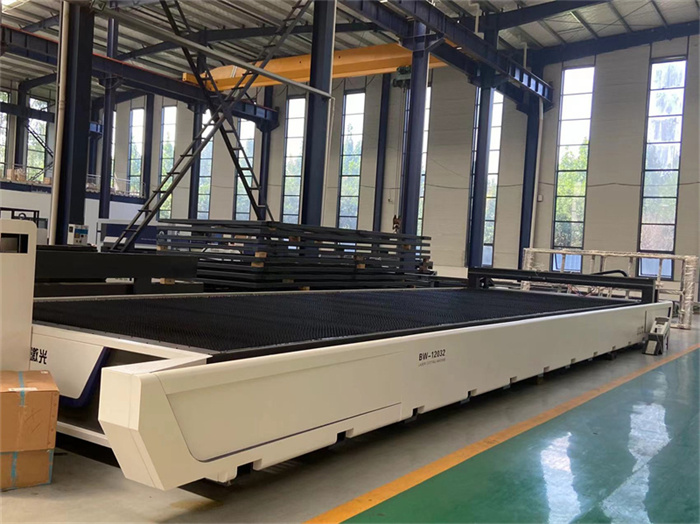

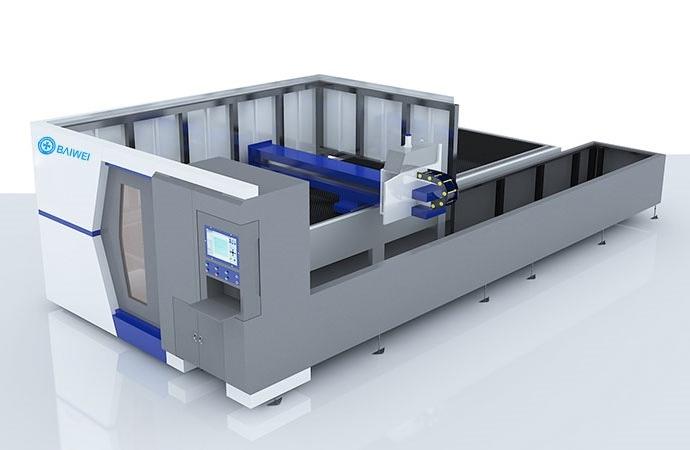

Name:Special laser cutting machine for pipes

Model:BWG-160/BWG-220/BWG-350/BWG-500

Laser Generator Medium: Fiber Laser

Max. Output Power:3000W/4000W/6000W/8000W

Effective pipe cutting diameter:≤499mm

Effective pipe cutting length:6000mm(Support non-standard customization)

In carbon dioxide laser cutting technology, carbon dioxide gas is the medium that generates the laser beam. Fiber lasers, however, work through diodes and fiber optic cables. Instead of transmitting the beam through a mirror, a fiber laser system generates a laser beam pumped by multiple diodes, which is then transmitted to the laser cutting head through a flexible fiber optic cable. This has many advantages, first and foremost the size of the cutting table. Unlike gas laser technology, where the mirror must be set within a certain distance, fiber laser technology has no range limit. And it is even possible to mount the fiber laser next to the plasma cutting head of the plasma cutting table, which is not an option for CO2 laser cutting technology. Also, the ability to bend the fiber makes the system more compact when compared to an equivalent power gas cutting system.