Super light cutting machine_High light cutting machine_High efficiency light cutting machine

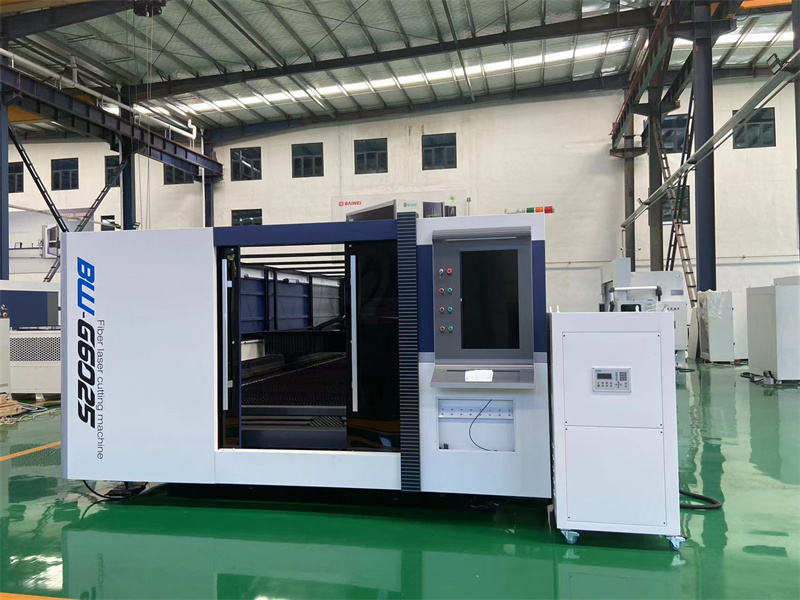

Model:BWQG6016-6000*160 professional tube laser cutting machine

Power:3kw/4kw/6kw/8kw

Cutting diameter: ≤499mm

Cutting length: 6000mm/9000mm/12000mm

Tube laser cutting is a non-contact cutting method that is very necessary in the entire future market. There will be no pressure during the processing of the pipe wall of the pipeline, nor will it collapse and deform. At the same time, when laser cutting pipes, the treatment of pipe cracks is also very good.

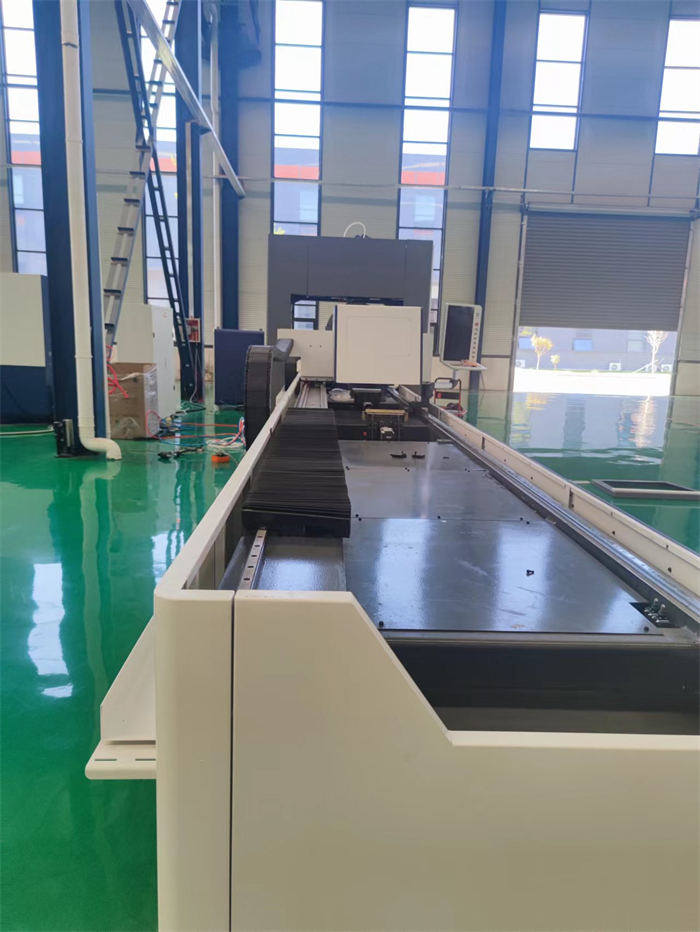

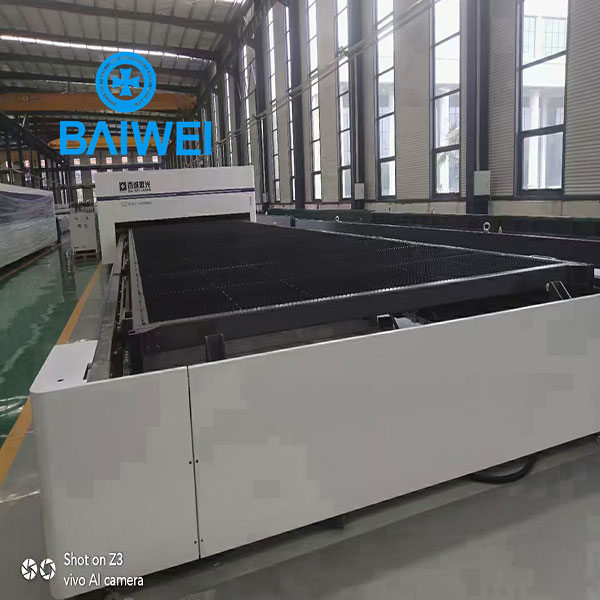

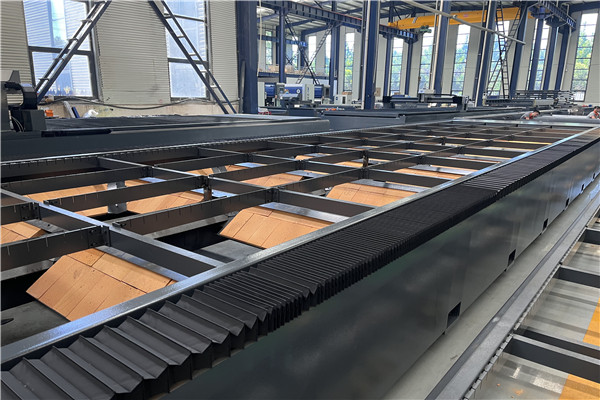

Tube laser cutting machine, specially designed for metal tube laser cutting. The double-chuck structure can cut metal tubes with a diameter of 20-500mm, maximum tube diameter we can do is 500mm, this is the largest model in this industry.equipped with a 1000w-6000w fiber laser, and the tube length can reach 3m, 6m, 9m, 10m ,12m etc. 2000w and above. The power supply is equipped with an independent cabinet and built-in air conditioner, and can be equipped with an automatic loading and unloading device to realize automatic processing.

Suitable material

Tube laser cutting machine is a laser cutting machine specially designed for cutting metal tubes. Can cut round tube, square tube, rectangular tube, oval tube, long tube (orbit circle), angle steel, channel steel, stainless steel tube, flat tube, U-shaped tube. Equipped with a special cutting operating system, the operation is simple, high precision, professional and stable, suitable for professional profile cutting, widely used in sports equipment, oil pipelines, chemical equipment and other industries.

Features of tube laser cutting machine

Tube laser cutting has the advantages of high cutting, small heat-affected area, fast cutting speed, good flexibility, and smooth cutting. There are many advantages and advantages in the machining process, such as no wear. With the emergence of laser cutting machines, there are more and higher requirements for free-form surfaces and curved surfaces in space.