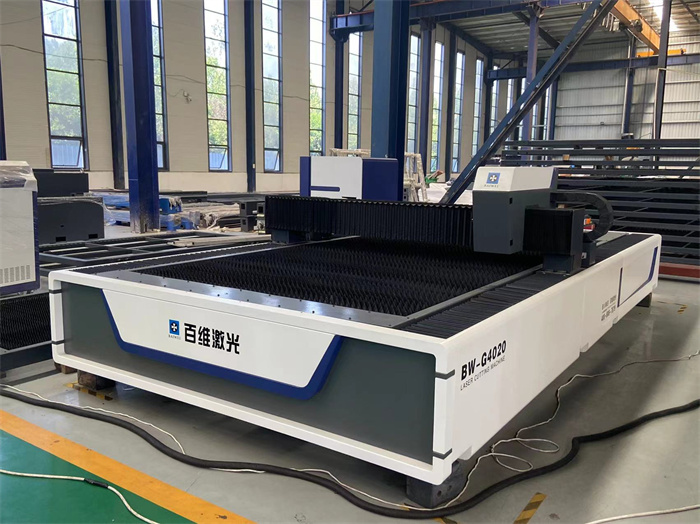

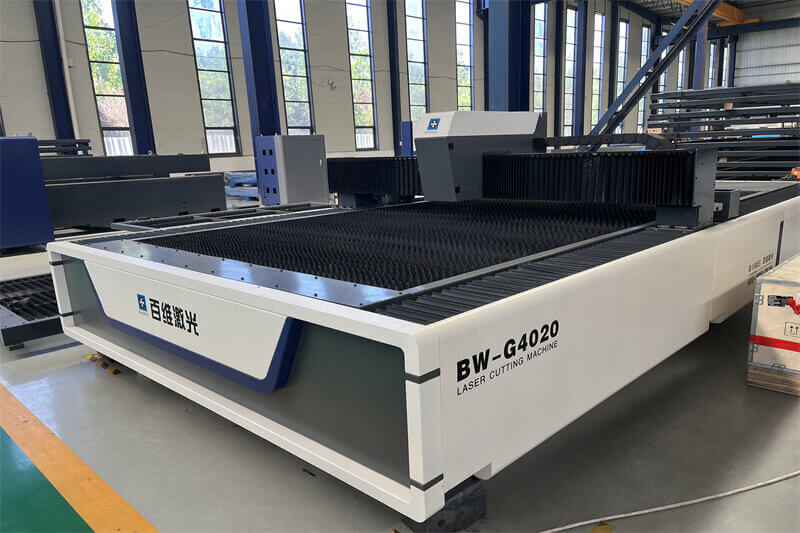

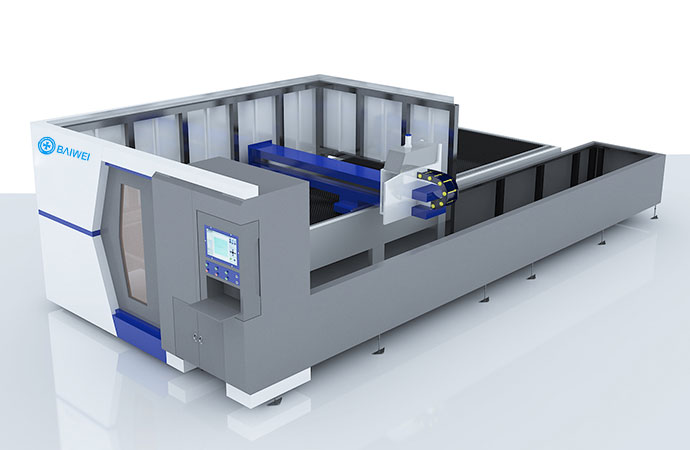

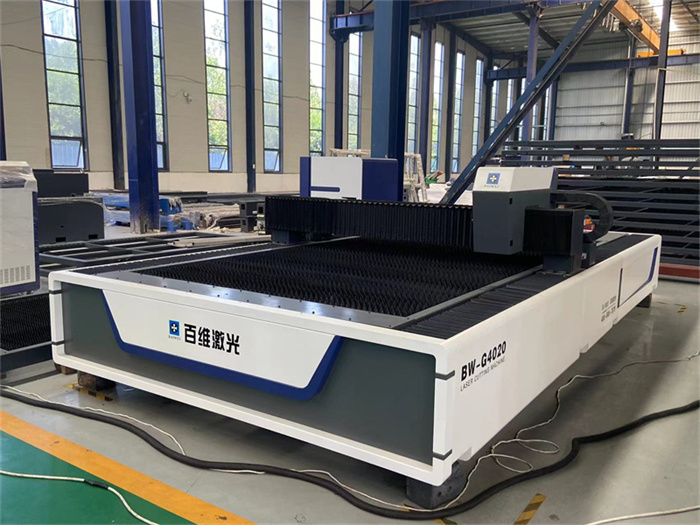

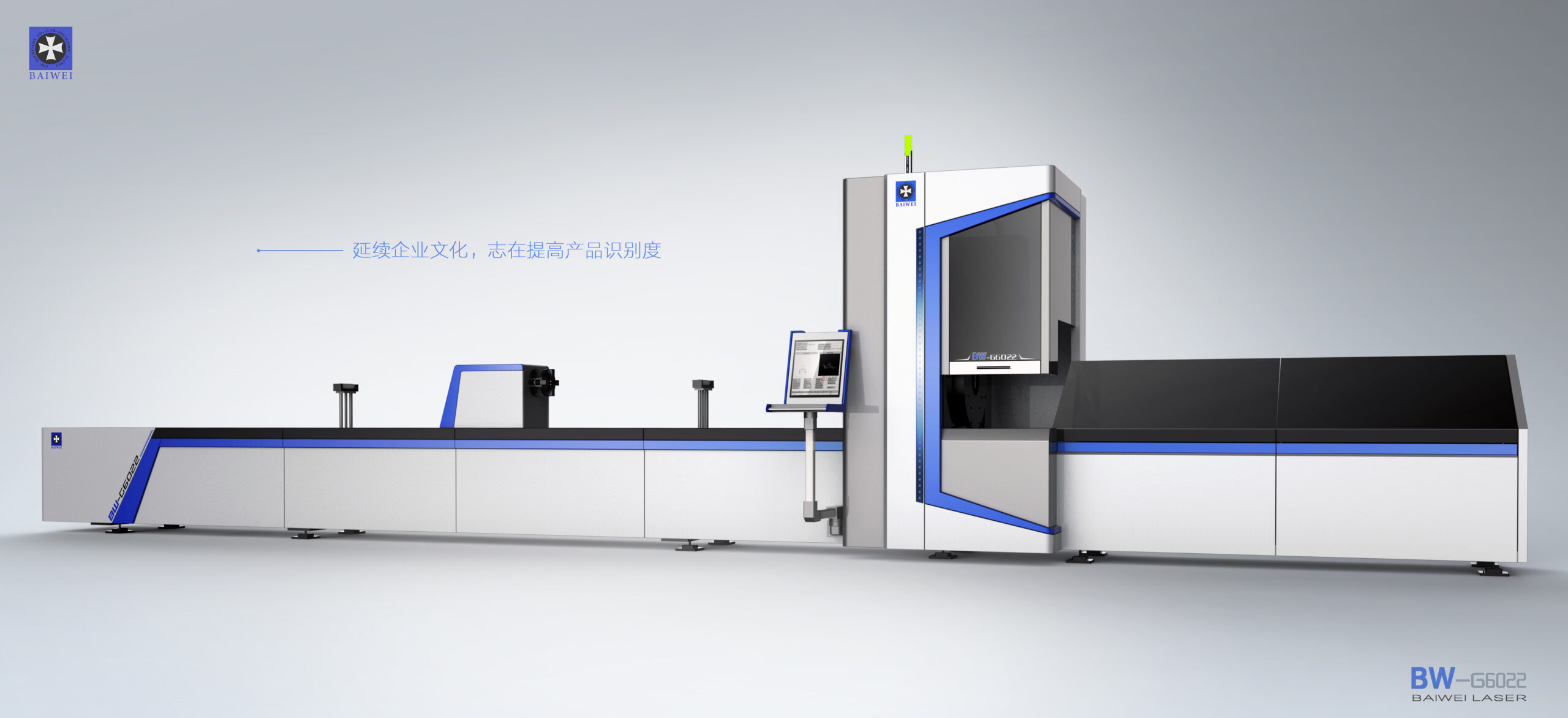

Steady closed type fiber laser cutting machine for carbon steel cutting

The enclosed fiber laser cutting machine adopts optical fiber transmission, no reflective lens, and no laser working gas. Therefore, the enclosed fiber laser cutting machine can save a lot of maintenance costs.

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

How many inches per minute can a laser cutter cut?

I have a 170 watt CO2 laser that cost in the low six-figures 7 years ago. It has a maximum cut speed of 10 inches per second (ips), so 600 inches per minute (ipm). I opted for the heavy duty rack and pinion drive system so it has minimal backlash and therefore is high accuracy. This lowered the maximum speed to the 10ips for cutting and 50ips for engraving. The regular version had an engraving speed of 70¨C100ips I believe.

Speed depends what you¡¯re cutting. I can cut cardboard at 10ips, but have to slow it down to 2ips to reliably cut 1/8¡å acrylic, or 0.1ips to cut 1¡å acrylic.