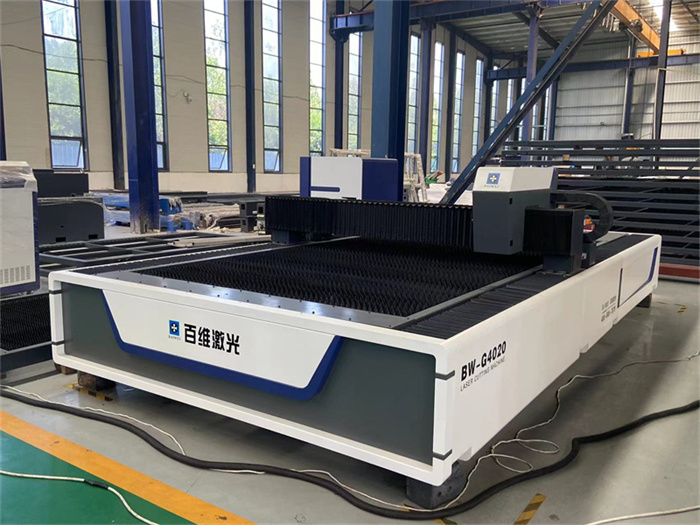

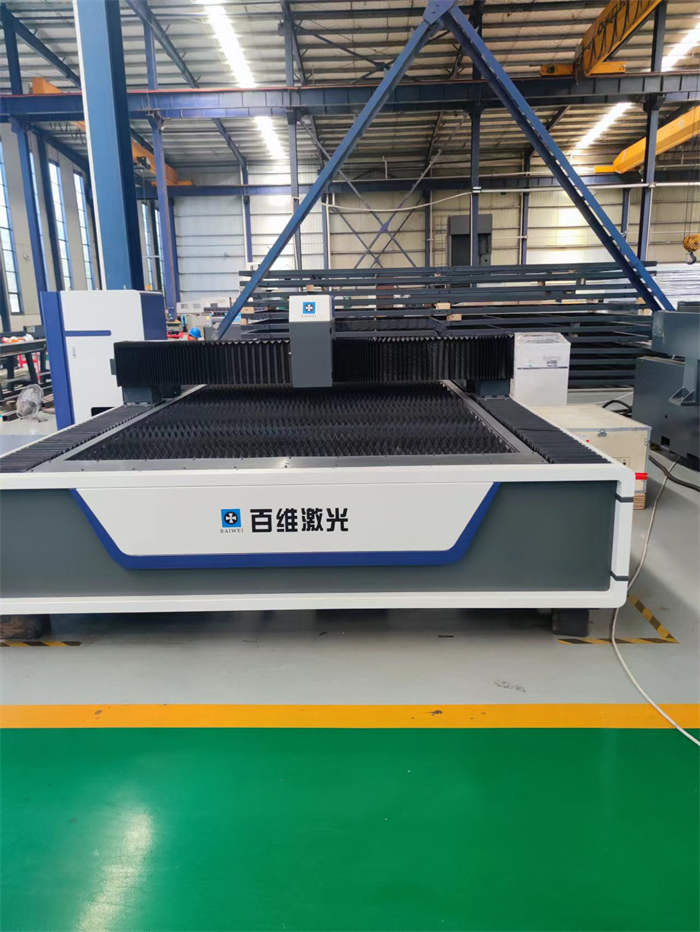

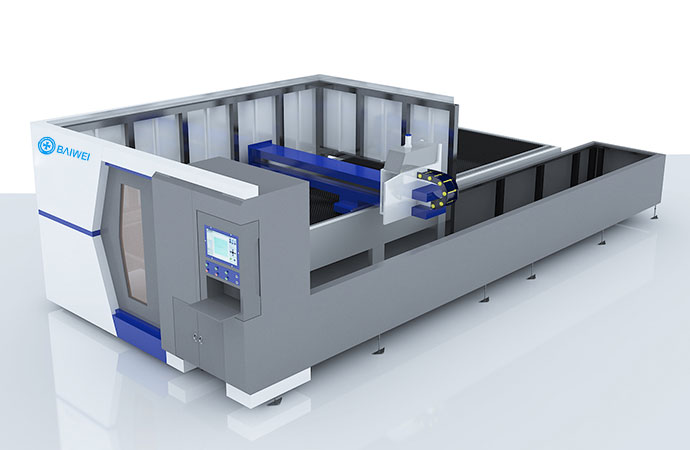

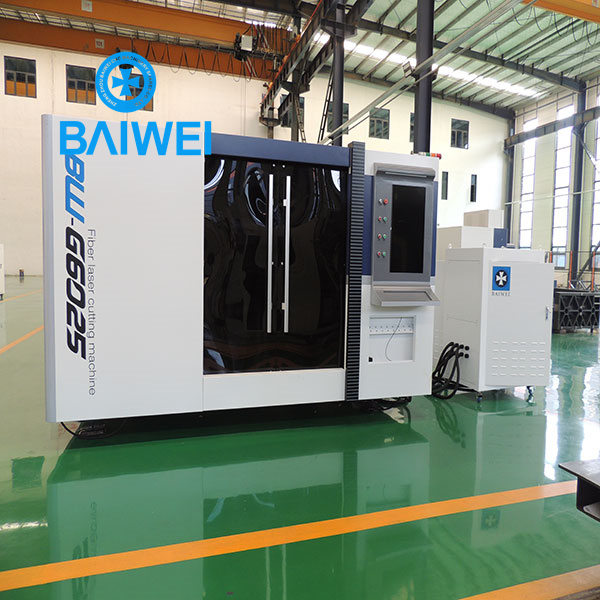

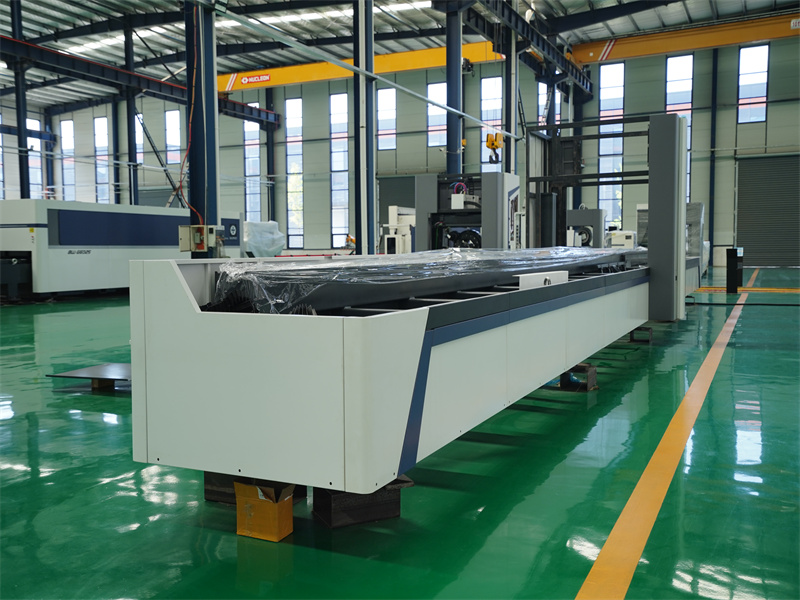

Stainless steel laser cutting processing equipment, can cut any graphics

Parameter

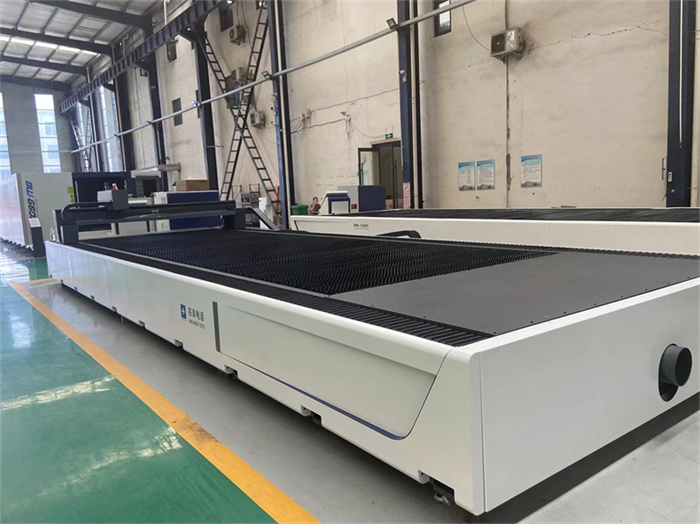

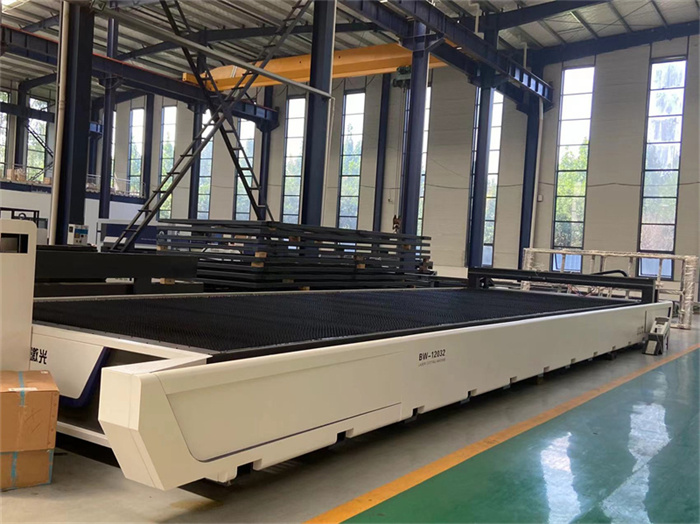

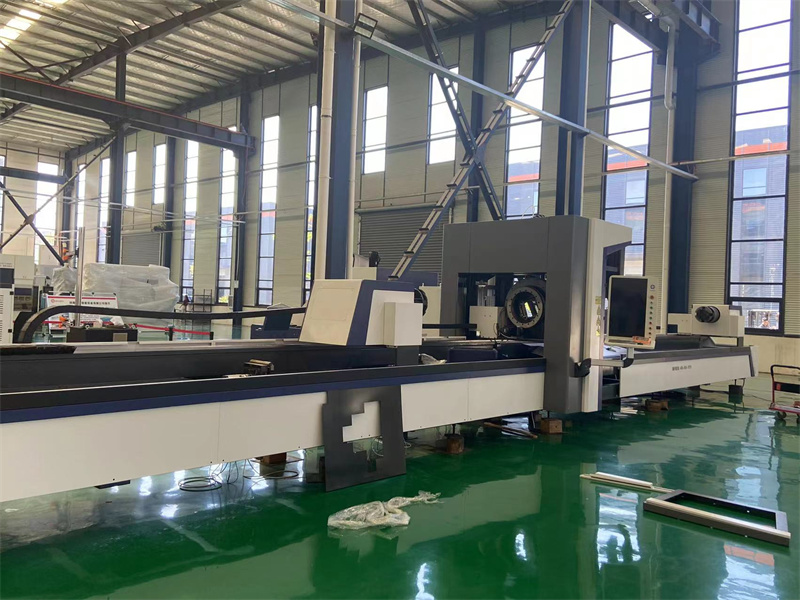

Models BW-G3015 BW-G4015 BW-G4020 BW-G6015 BW-G6020 Optional

Cutting range 3000x1500mm 4000x1500mm 4000x2000mm 6000x1500mm 6000x2000mm Optional

Laser power 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw

Max moving speed 100m/min

Max cutting speed 35-80m/min

Positioning accuracy 0.03mm

Repositioning accuracy 0.02mm

Min line width 0.1mm

Carbon steel, stainless steel

The maximum thickness of modern laser cutting machine can cut carbon steel plate up to 20MM, the cutting seam of carbon steel can be controlled within a satisfactory width range by using the oxidation melting cutting mechanism, and the cutting seam of thin plate can be narrowed to about 0.1MM. Laser cutting is an effective tool for manufacturing that utilizes stainless steel sheets as primary components. Under the strict control of the heat input in the laser cutting process, the heat-affected zone of the cutting edge can be limited to become very small, thereby effectively maintaining the good corrosion resistance of such materials.

Stainless steel

Oxygen and nitrogen are generally used for cutting stainless steel. When the edge oxidation has an impact on the next process, nitrogen can be used to obtain a non-oxidized and burr-free edge, which can be used without subsequent treatment. Coating an oil film on the surface of the sheet will result in better perforation without compromising machining quality.