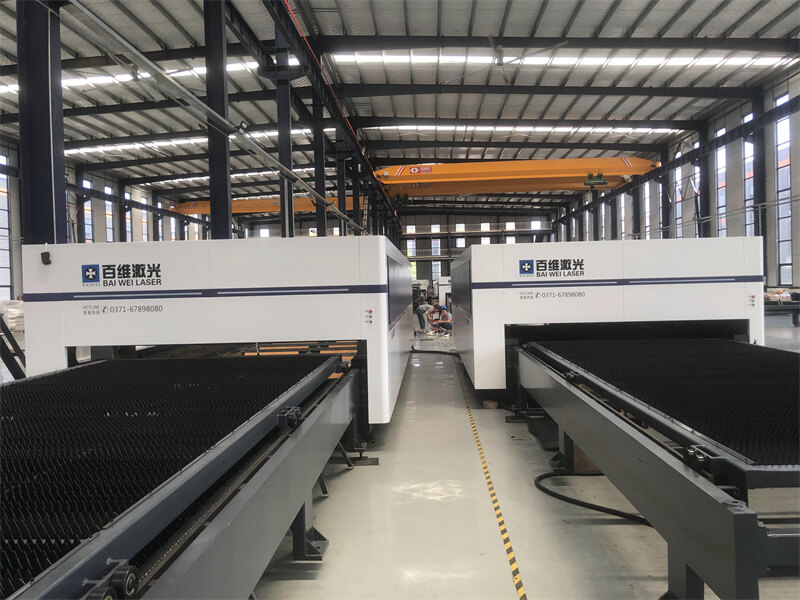

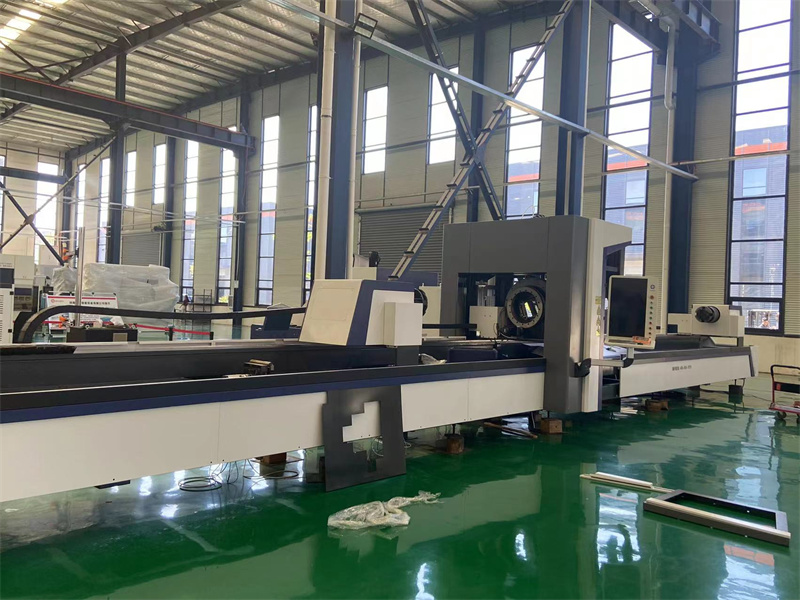

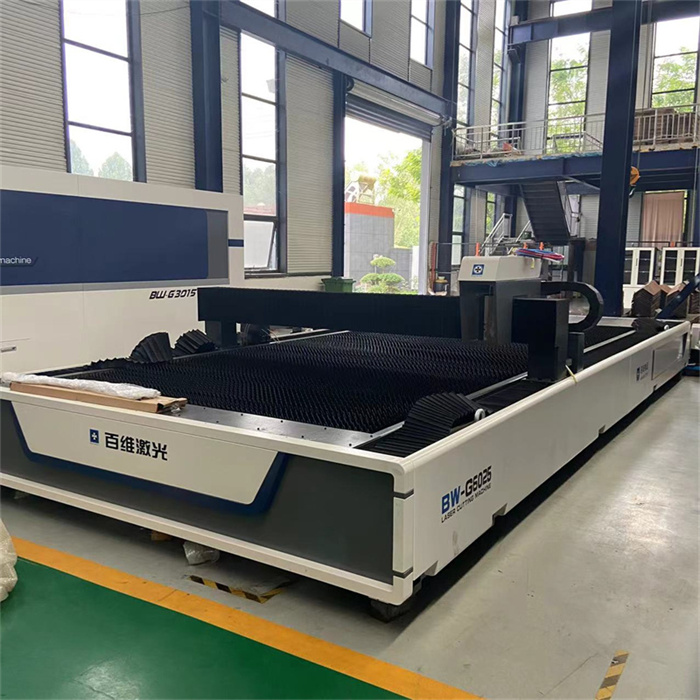

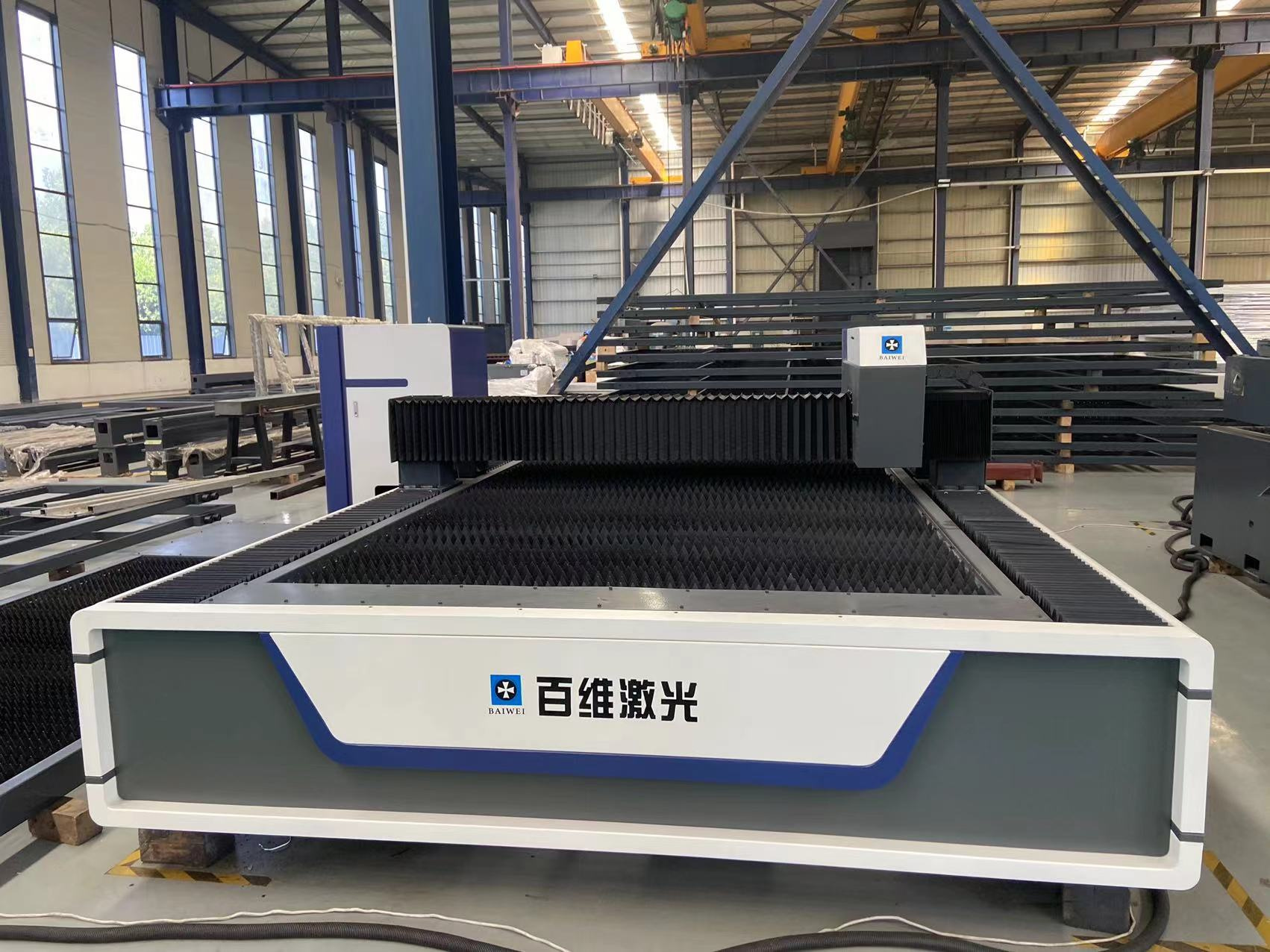

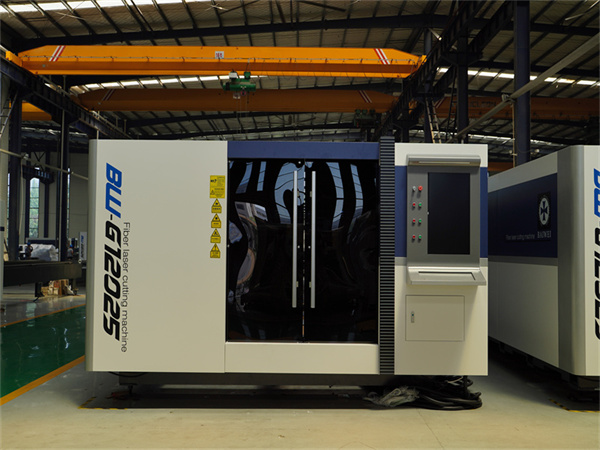

Stabilized BW-G6025 closed type fiber laser cutting machine for steel sheet

The BW-G6025 closed type fiber laser cutting machine adopts the double-sided drive mechanism of the rack, which greatly improves the running speed of the equipment. BW-G6025 closed type fiber laser cutting machine can reach more than 100m/min empty distance.

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

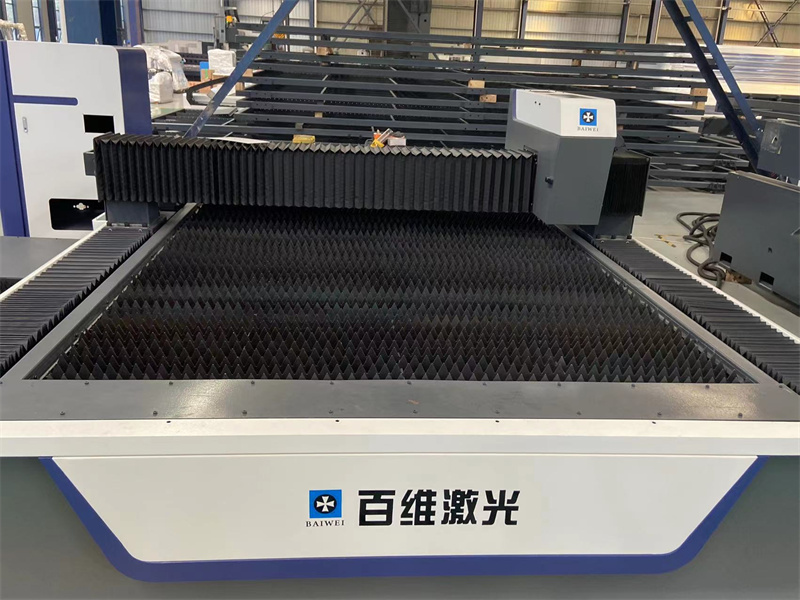

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

¡¡

How do I get a cheap laser cutting machine?

Originally Answered: How can I get a cheap laser cutting machine?

The price of laser cutting machines ranges from tens of thousands to hundreds of thousands or even millions. Customers need to choose a cost-effective product based on their actual needs.

The first thing you need to do to determine the purpose of your machine is to see what material you are cutting. Cutting material shape? Processing accuracy? Processing material thickness? Used for fine processing or primary processing? The final product requirements? According to their own business scope and then determine the need to purchase the power of the device and the size of the table, the current market power laser cutting machine between 500w-4000w, and the size of the workbench in general manufacturers can be customized according to customer needs .

After determining the requirements, we can go to the market to learn about it or go to a colleague who has purchased a laser cutting machine to first look at the performance and basic parameters of the machine. Select several companies with strong price and preferential prices to conduct preliminary communication and proofing. In the later period, we can carry out on-site inspections and conduct more detailed discussions on machine prices, machine training, payment methods, and after-sales services. Must go to the scene to visit the workshop situation, and the corresponding technical personnel to communicate the details of the problem. In the face of their own problems can not be solved, the vendor can provide timely solutions is particularly important, and this is an important factor that we need to consider when purchasing a laser cutting machine.

The final accessory is very important. When purchasing a laser cutting machine, it is important to observe the configurations used by the laser cutting machine manufacturers, such as laser cutting heads, lasers or transmission systems, which are all critical parts. Buyers must carefully and carefully measure and evaluate.

Finally consider the cost-effective, choose a suitable product.