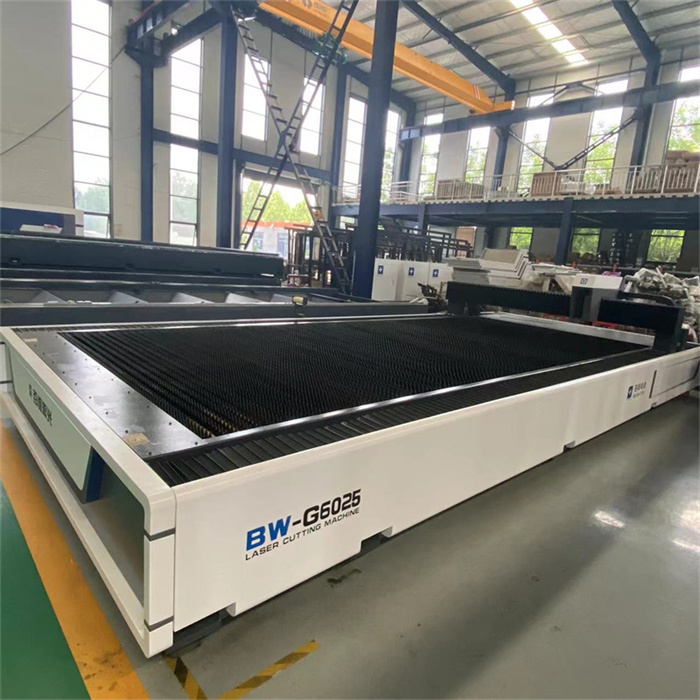

Stabilized BW-G6025 closed type fiber laser cutting machine for metal sheet

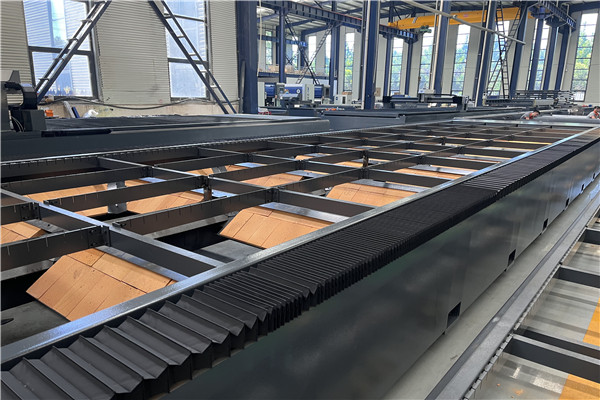

The laser of BW-G6025 closed type fiber laser cutting machine is transmitted by optical fiber, no reflective lens is needed, which can save a lot of maintenance cost. In addition, the cutting seam of BW-G6025 closed type fiber laser cutting machine is thin, and the cutting seam of laser cutting is generally within 0.2mm.

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

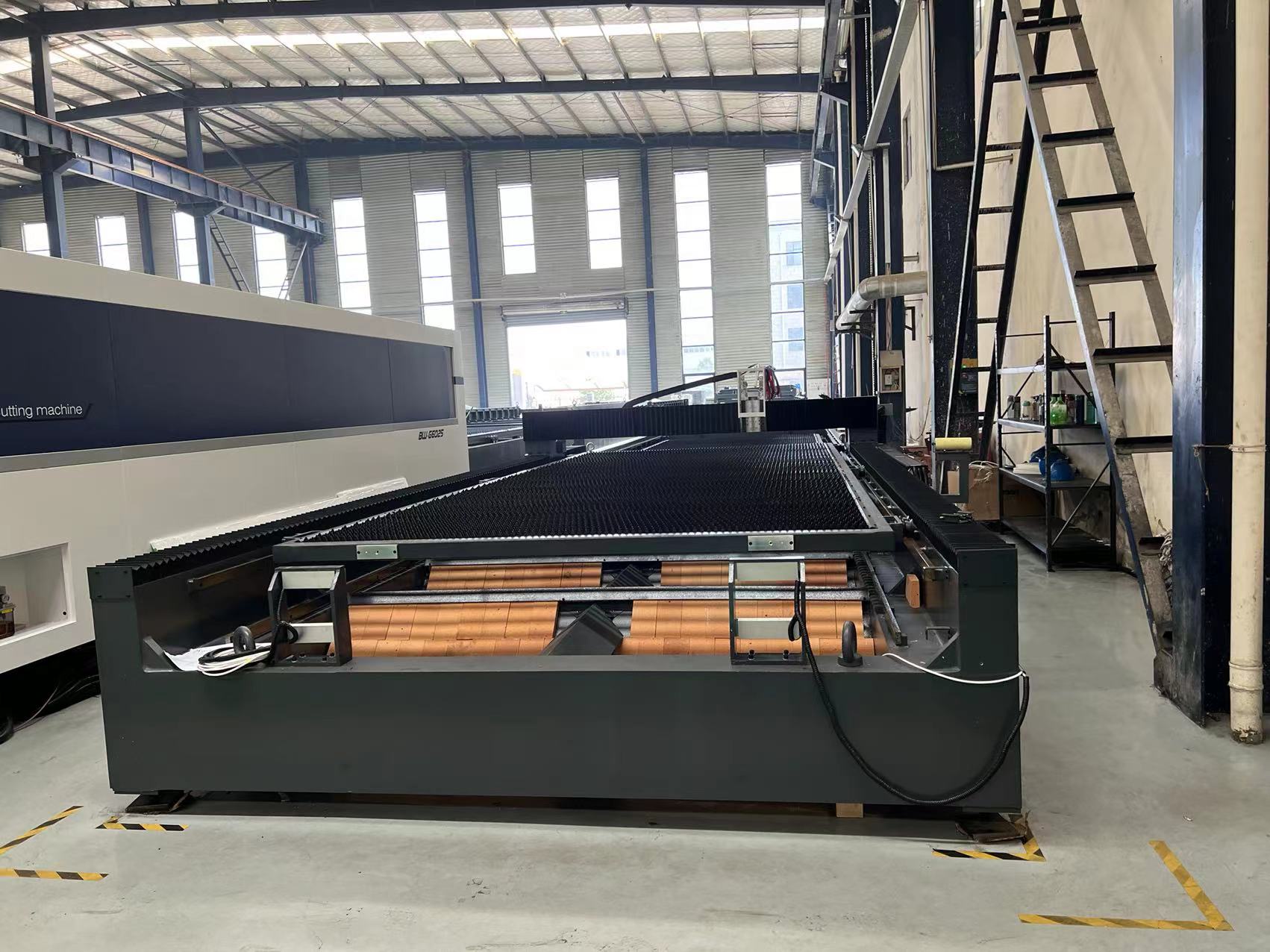

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

¡¡

What is the working principle of a fiber laser cutting machine?

Fiber laser cutting machine makes full use of the optic laser beam to process different kinds of metal material. It has a wide range of application in the manufacturing industry, hardware industry, furniture industry, etc.

Fiber laser cutting machine is one of the laser cutting equipment, which utilizes light power to pierce the processing material. In comparison with normal light source, laser generator has its unique character, like great directionality, monochromaticity, coherence and energy concentration. Among these factors, monochromaticity depends on the frequency stability, while the best monochromaticity could be realized by the gas laser generator.

If you want to improve the quality of monochromaticity, frequency stabilization technology and mold selection technology could be adopted.

The basic operation principle is the photoelectric conversion, the laser generator is driven by the electronic power, and transport the optical fiber into the cutting head.