Home » Fiber Laser Cutting Machine » Single platform double laser cutting machine metal carbon steel stainless steel sheet plane laser cutting equipment

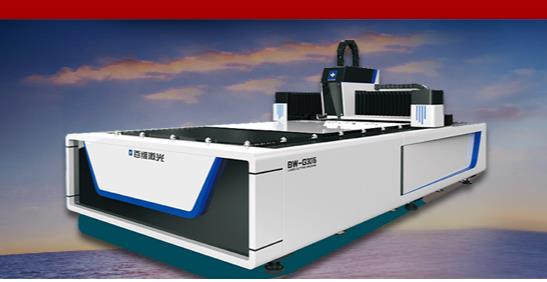

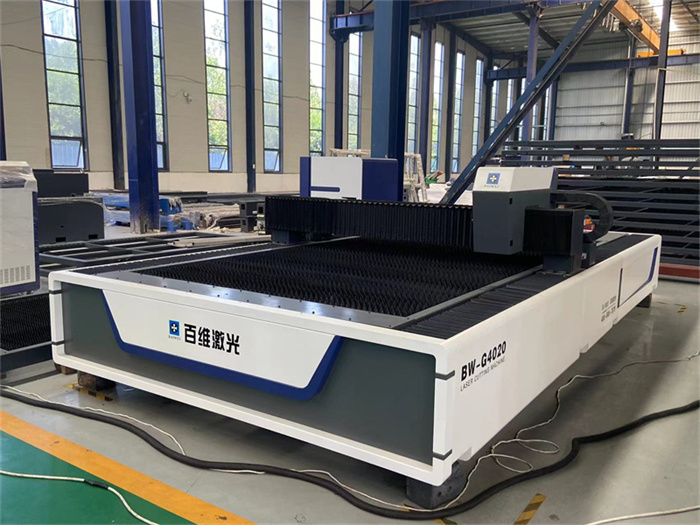

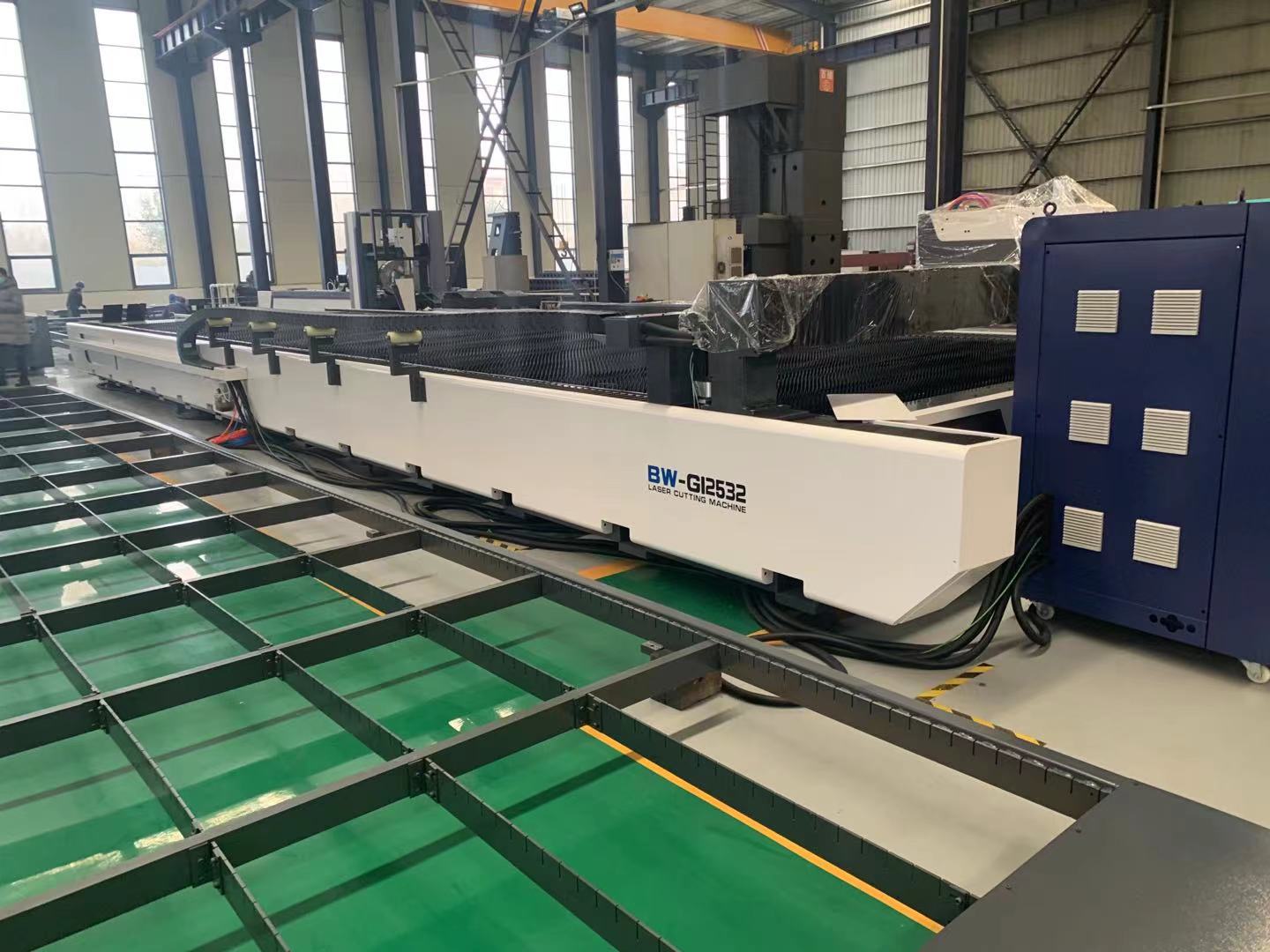

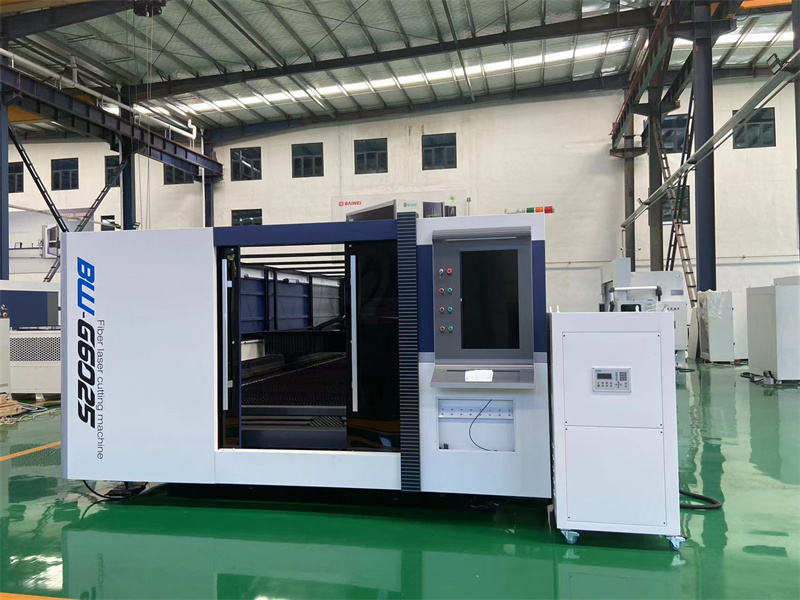

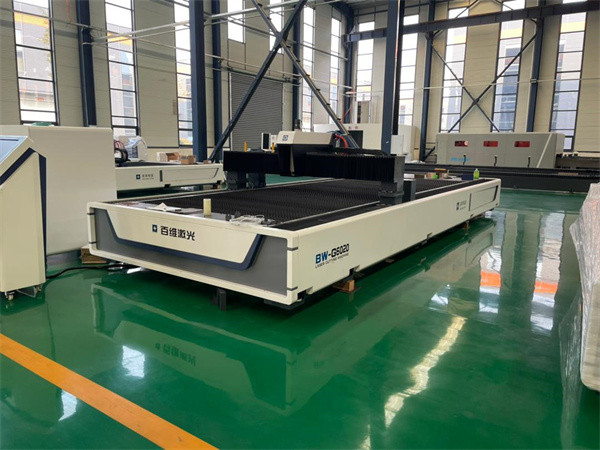

Single platform double laser cutting machine metal carbon steel stainless steel sheet plane laser cutting equipment

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Contact US

Get Price

Share:

Content

Pulse perforation uses a pulsed laser with high peak power to melt or vaporize part of the cutting track of the material. Air or nitrogen is often used as an auxiliary gas to reduce the expansion of the hole due to exothermic oxidation. Each pulse produces only a tiny spatter, and the cut is progressively deeper, so the piercing time for thick plates takes a few seconds. In this way, the diameter of the perforation is smaller, and the perforation quality is better than that of blasting perforation. The advantage is that the quality is better, and the disadvantage is that the cost is relatively high, and a more reliable pneumatic control system is required.

The laser cutting process uses the energy released when a laser beam hits the surface of the steel plate to melt and vaporize the stainless steel. The laser source generally uses a carbon dioxide laser beam with a working power of 500-2500 watts.

High Configuration Laser cutting replaces traditional mechanical knives with invisible beams. It has the characteristics of high precision, fast cutting, not limited to cutting patterns, automatic typesetting to save materials, smooth incisions, and low processing costs. It will be gradually improved or replaced. Traditional metal cutting process equipment.

Controlled fracture cutting:For brittle materials that are easily damaged by heat, high-speed and controllable cutting by laser beam heating is called controlled fracture cutting. This cutting process is mainly: the laser beam heats a small area of brittle material, causing large thermal gradients and severe mechanical deformation in this area, resulting in the formation of cracks in the material. The laser beam can direct cracks in any desired direction as long as a uniform heating gradient is maintained.

Inquiry

More Fiber Laser Cutting Machine