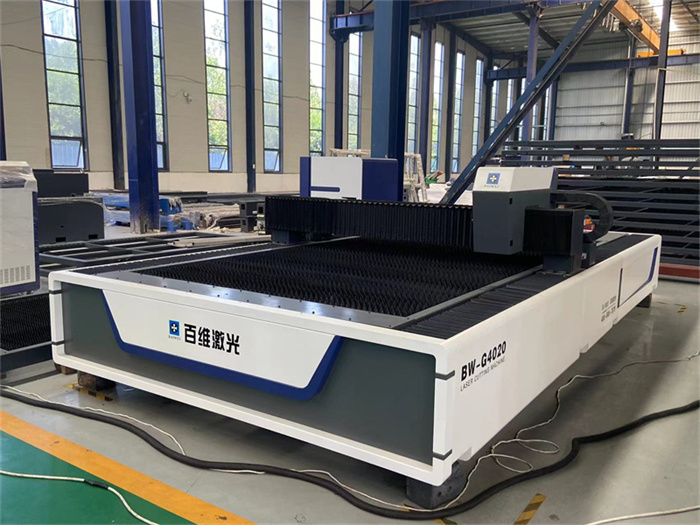

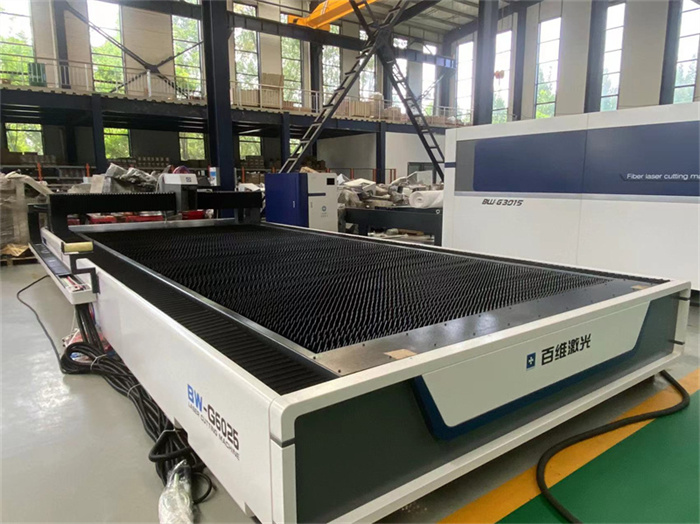

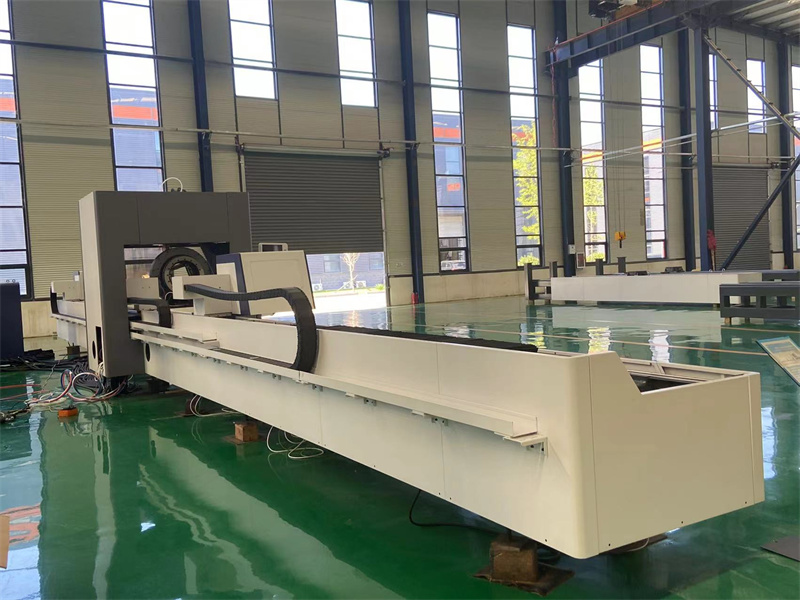

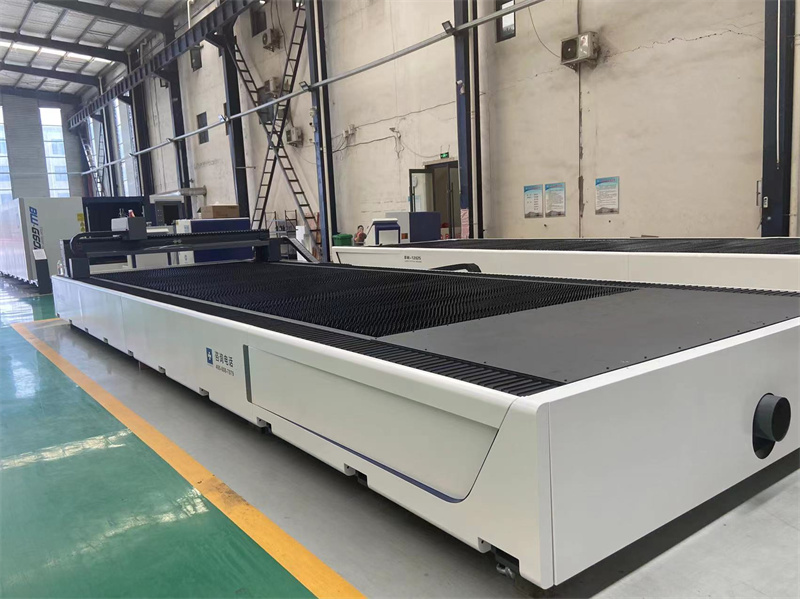

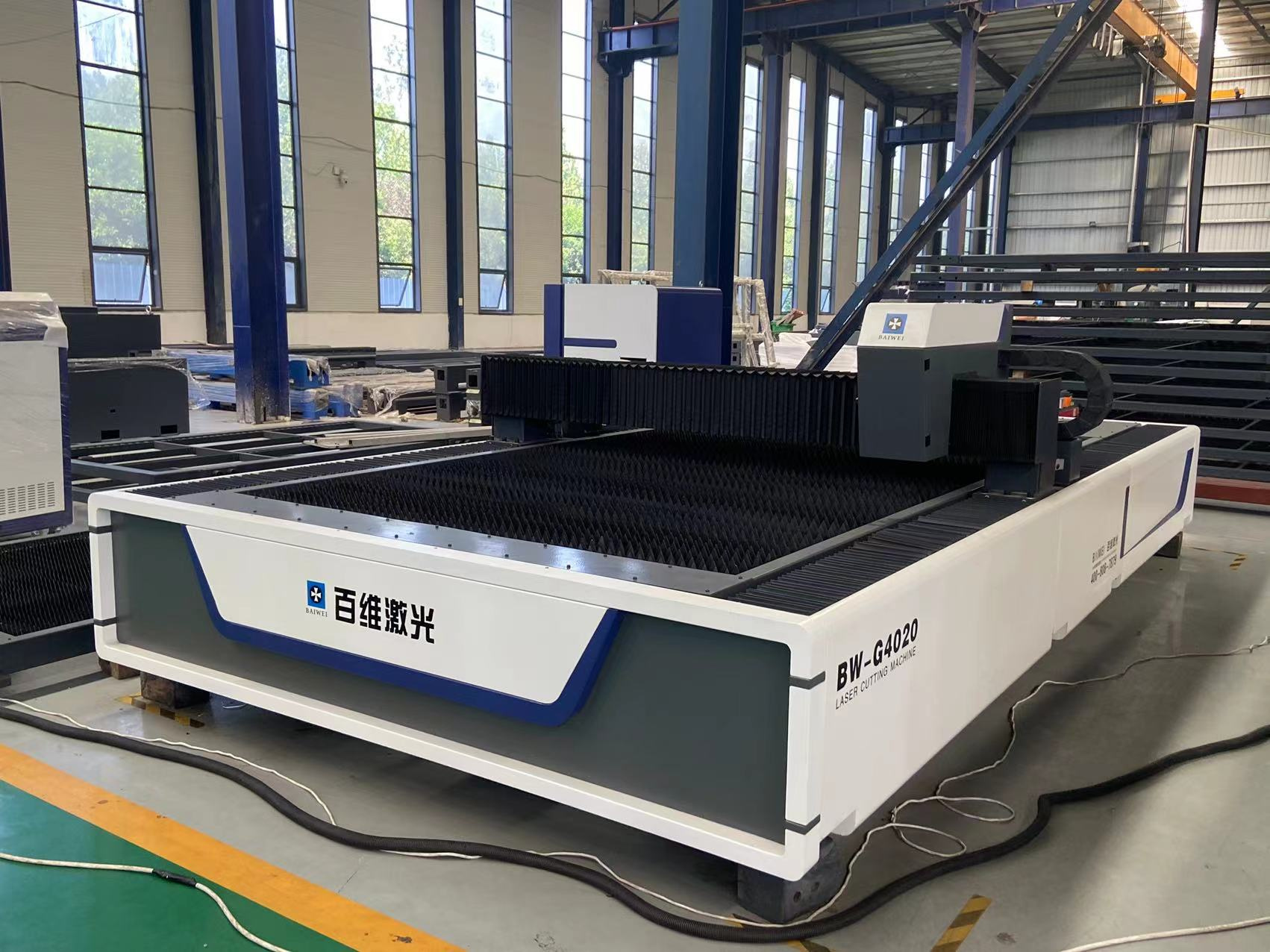

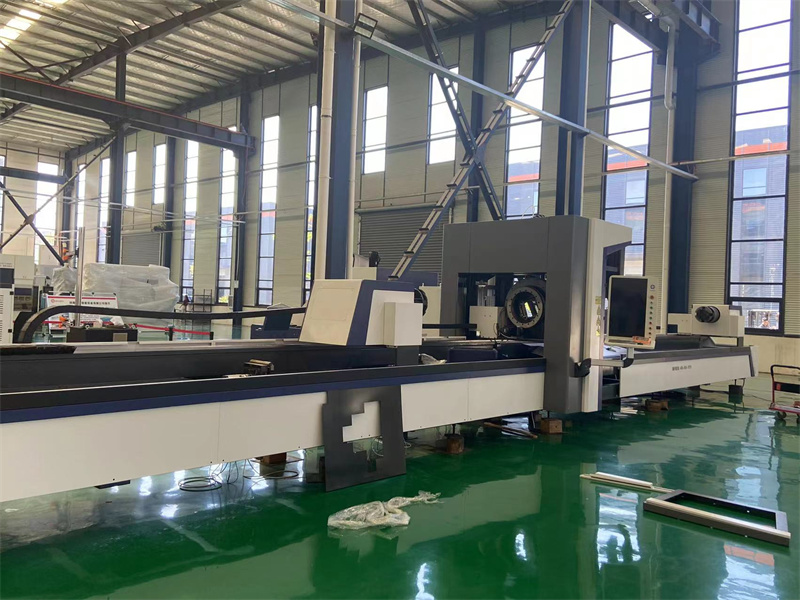

salable open type fiber laser cutting machine steel plate cutting

Model: BW-G3015

Cutting range: 3000x1500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 100m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Regular Maintenance of Machine Tools

1) Clean up the debris at the exhaust vent regularly to ensure the exhaust effect.

2) Regularly check the filter in the air path, and remove the water and debris in the filter in time.

3) Regularly check whether the limit switch bracket and the striker bracket screws are loose.

4) Clean the dust on the ventilation fan filter of the electric control cabinet in time to ensure good ventilation to facilitate the heat dissipation of the internal electrical components.

5) Every other week, you must check the lubricating oil filling of the X-axis guide rail and lead screw, Y-axis guide rail and lead screw, Z-axis guide rail and lead screw to maintain the lubrication of all moving parts. Thereby prolonging the service life of X, Y, Z axis guide rails and lead screws.

6) According to the environment of the workshop, check the contamination of the reflector and focusing mirror surface from time to time, and clean the optical lens in time to ensure its service life.