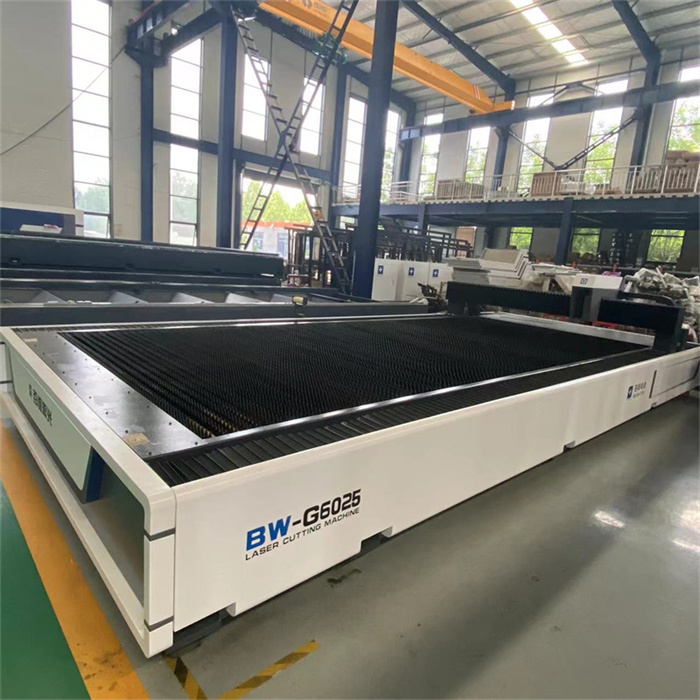

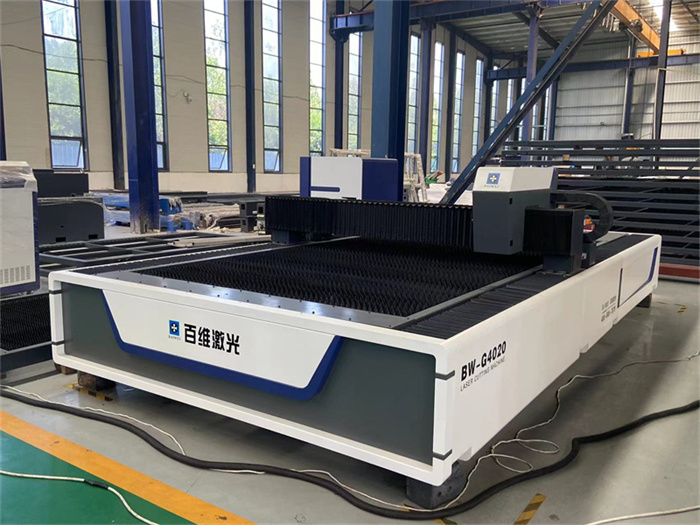

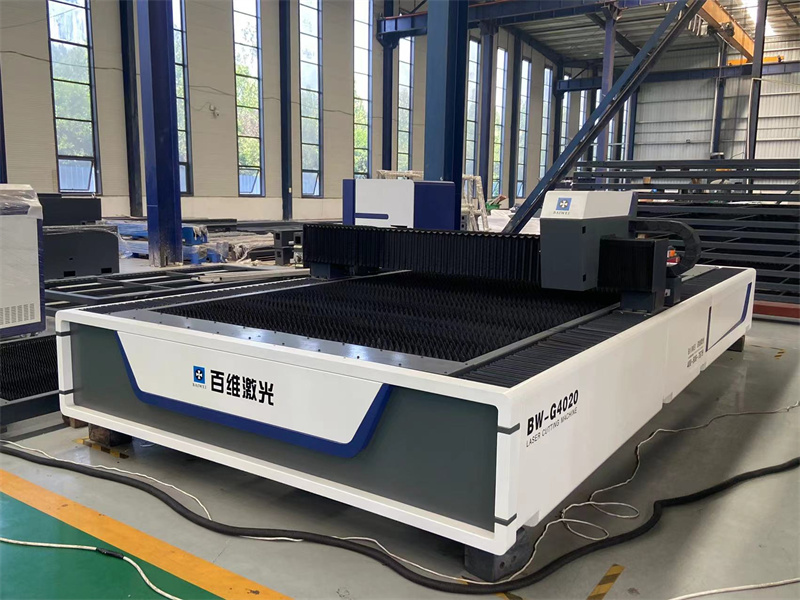

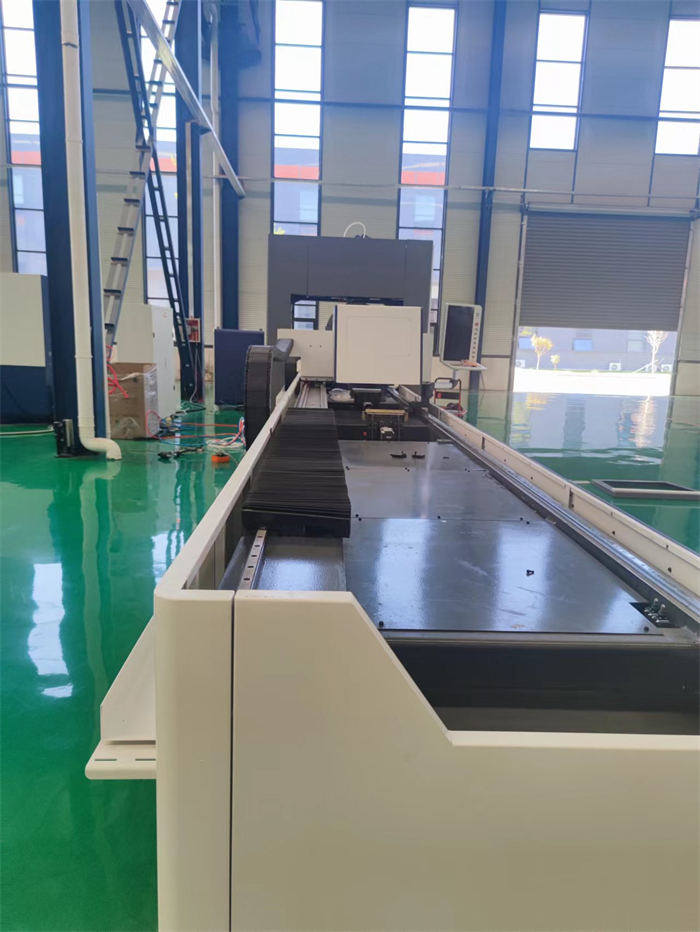

Salable BW-G6025 closed type fiber laser cutting machine for sheet metal

BW-G6025 closed type fiber laser cutting machine does not need molds during laser processing, and there is no mold consumption. In addition, the BW-G6025 closed type fiber laser cutting machine does not need to repair the mold, saves the time of replacing the mold, and thus saves the processing cost.

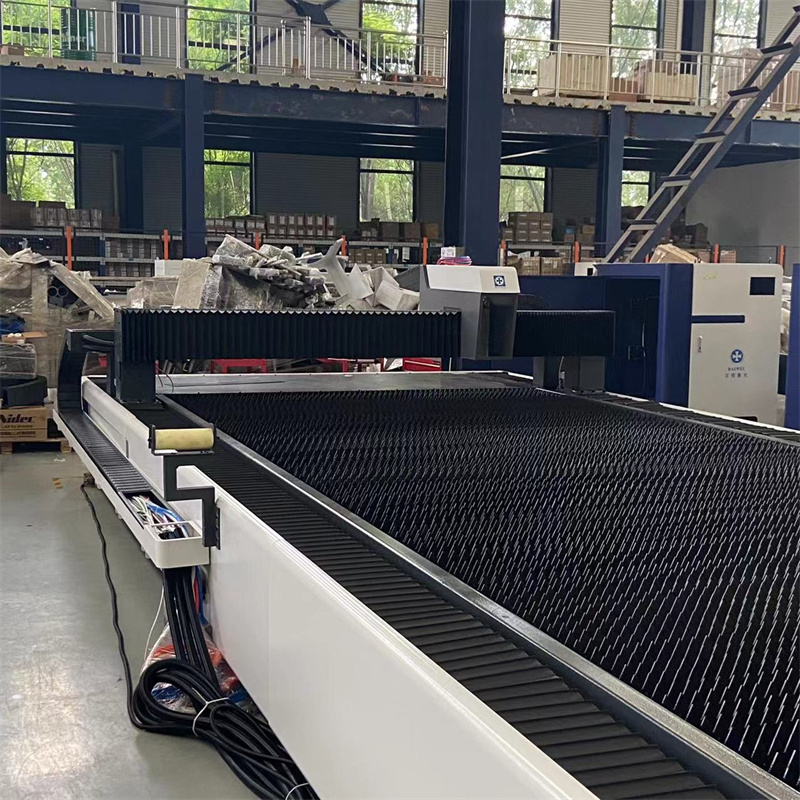

Cutting range 3000x1500mm 4000x1500mm 4000x2000mm 6000x1500mm 6000x2000mm Optional

Laser power 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw

Max moving speed 100m/min

Max cutting speed 35-80m/min

Positioning accuracy 0.03mm

Repositioning accuracy 0.02mm

Min line width 0.1mm

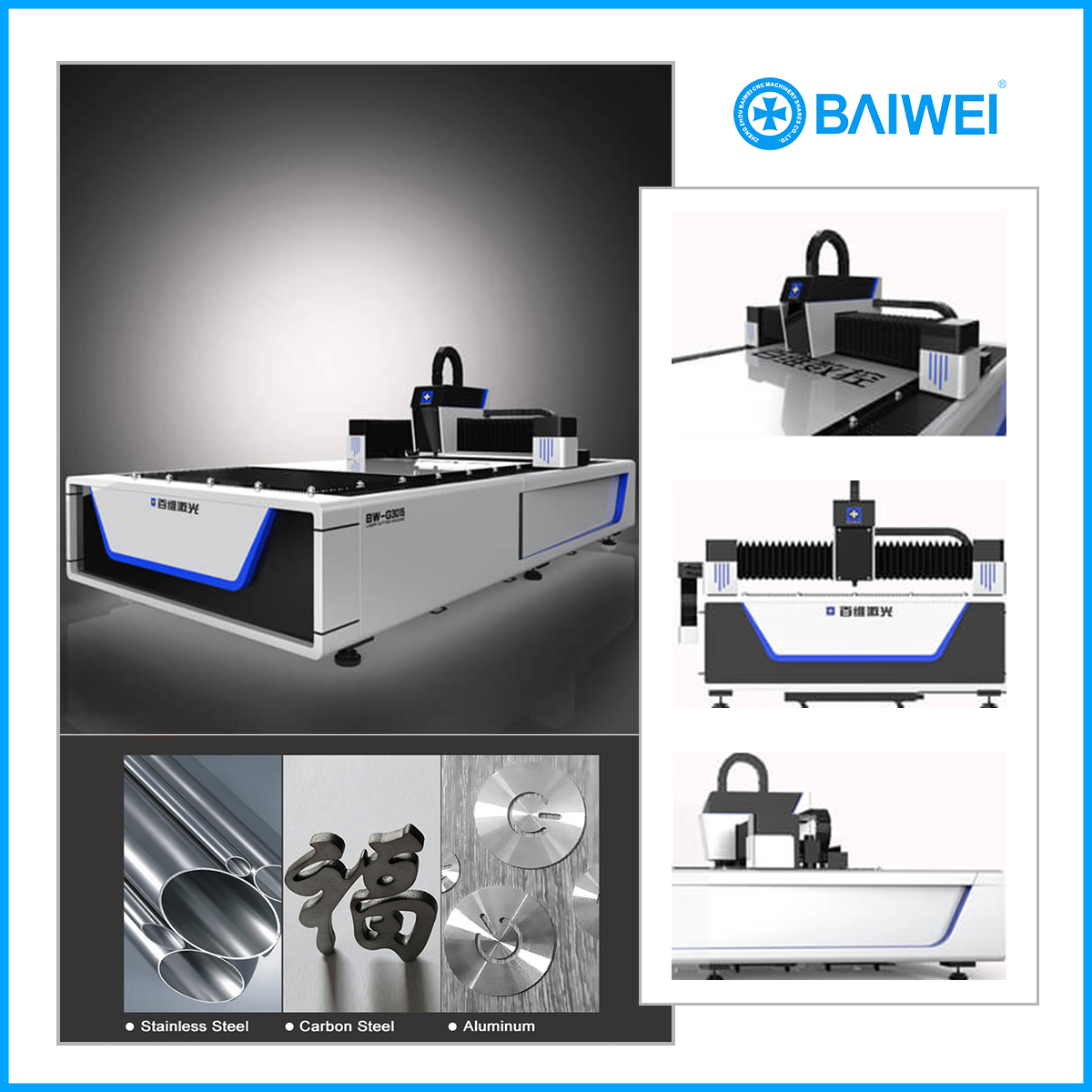

Why is fiber laser cutting machine more and more popular?

The short answer is that you can focus the fiber laser wavelength to a tighter spot size, and get higher energy density. This allows for faster cutting for the same laser power, at least in materials thinner than 3 mm thick, than the same power CO2 laser would be able to do. They also have less maintenance, since there aren’t mirrors to routinely realign, and they have higher wall plug efficiency, so they cost less in electricity in the long run. For many equipment purchasers, these long term effects mean they will make more money laser cutting, and can mostly ignore the benefits a CO2 laser has on thick material, since it is only marginally more expensive to just purchase a higher power fiber laser.