Home » Fiber Laser Cutting Machine » Optical Fiber Automatic Laser Tube Cutting Machine Baiwei Laser Tube Cutting Machine Cutting Machine

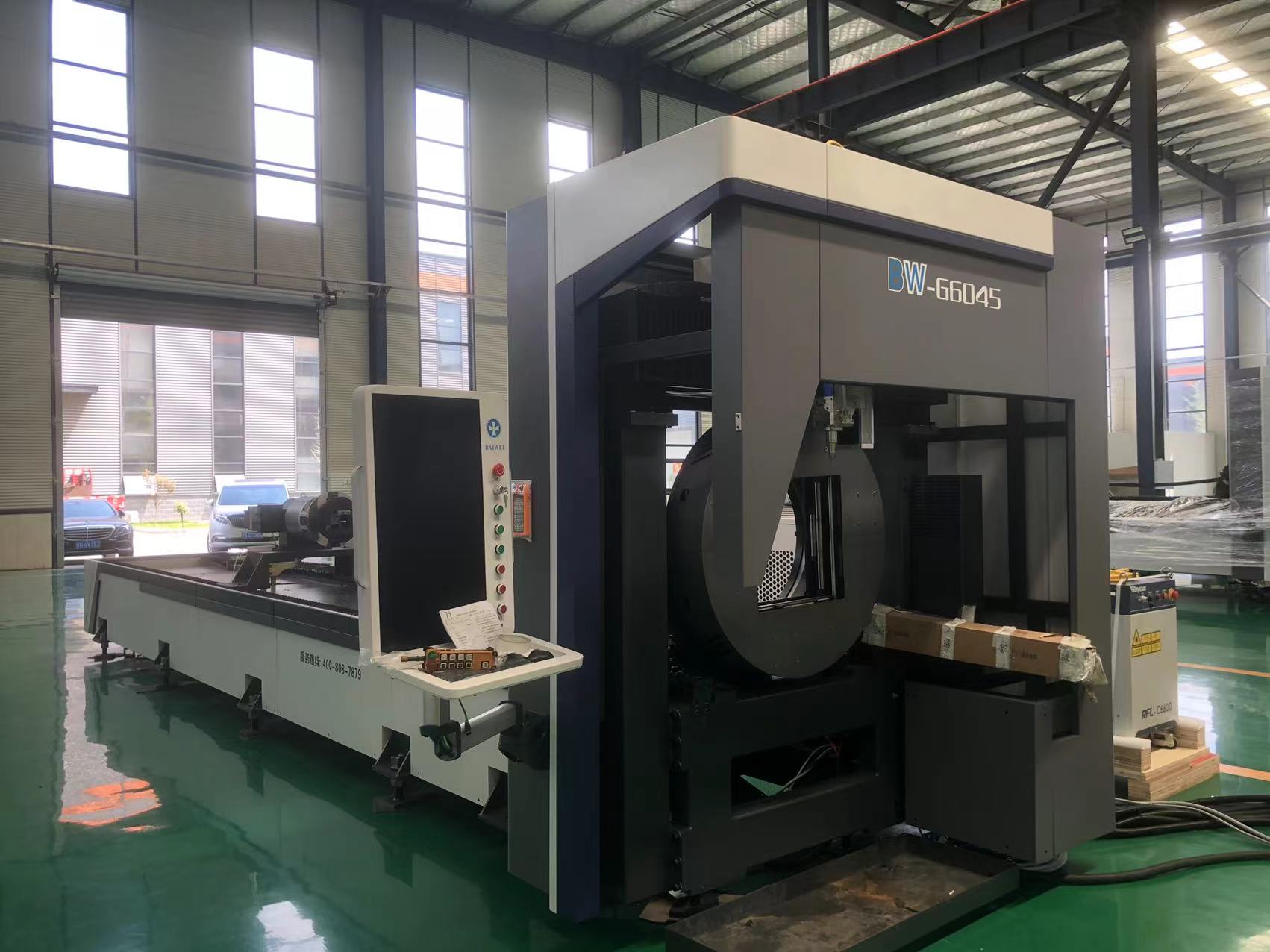

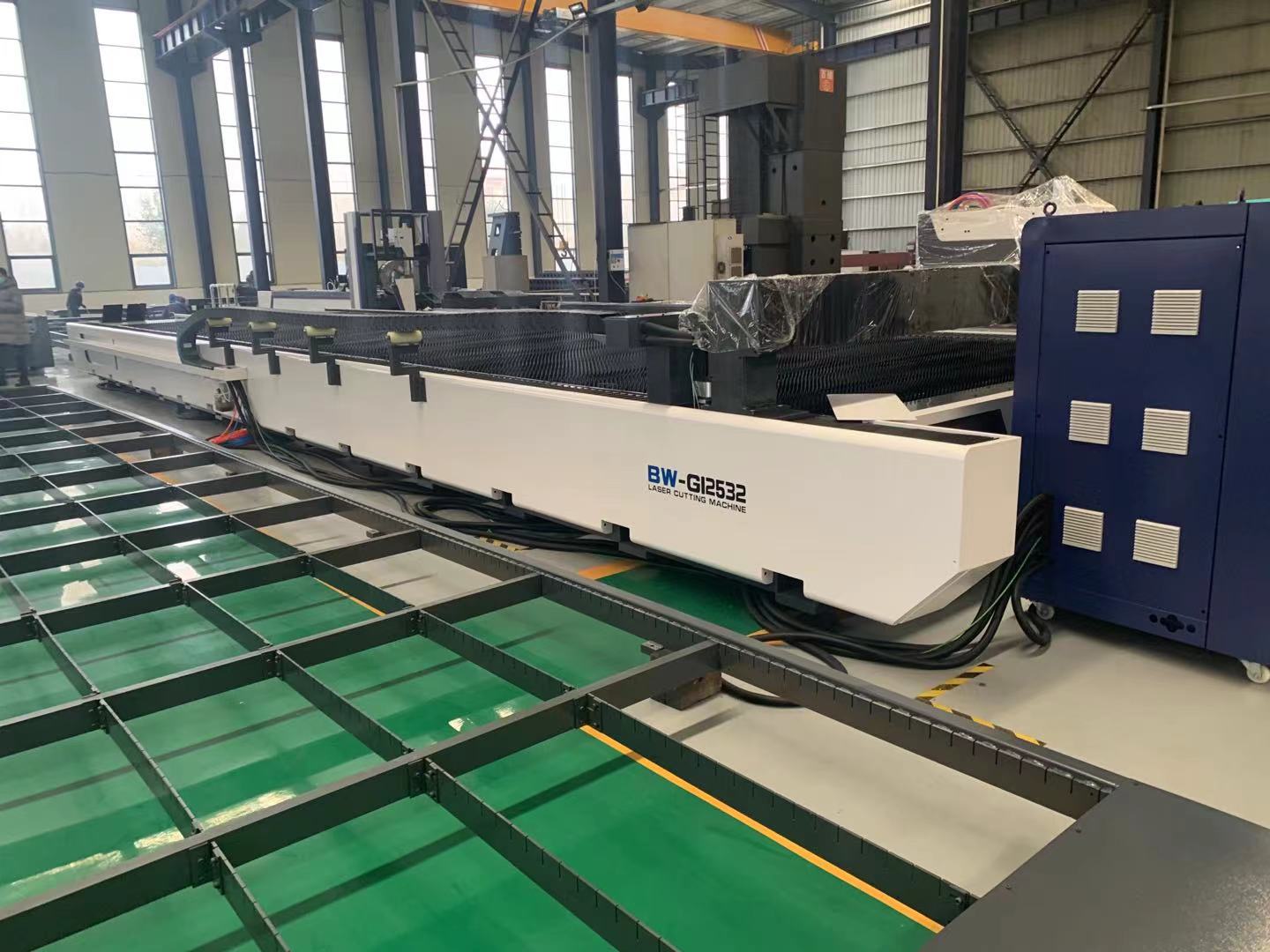

Optical Fiber Automatic Laser Tube Cutting Machine Baiwei Laser Tube Cutting Machine Cutting Machine

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Contact US

Get Price

Share:

Content

What is Laser Cutting and How Does it Work?Many manufacturing industries use computer numerical control machines nowadays to speed up their production processes. These machines use several processes, and one of them is laser cutting. Basically, all computer numerical control machines involve giving commands to machines after transforming the digitalized drawing into a computer language.

This language gives the device the instruction needed for executing the designs. The relationship between the language and the machine is like when you send a picture to a printer. Also, this is the same way laser cutting machines work, and they can execute the designs in a short time.

The laser cutting product design allows it to use 2D vector files for guiding lasers. It is made up of a laser resonator. This resonator has glass fibers or sometimes may contain a gas mixture of crystal bodies. The constituent resonator depends on the designer’s method to cut the materials. The application of the energy to the mix will begin the process of cutting. Then, the laser is focused after sending the mixture through different mirror lenses.

How Does Laser Cutting Work?Before diving into laser cutting advantages and disadvantages, it is essential to understand how it works. The way how laser cutting machines work is similar to CNC machines work, but it uses a high-power laser. The laser will guide the material or beam by directing itself through CNC and optics. The device will use the CNC, or G-code provided, to cut into the material and control the motion.

Melting, vaporizing, and burning the material will occur after focusing the laser beam. Also, you can acquire a finished edge surface of high quality when you blow the material with a jet of gas. The creation of a laser beam occurs in a closed container by stimulating lasing materials through lamps or electrical discharge.

The amplification of the lasing materials then takes place after reflecting internally through a partial mirror. The phenomenon continues until enough energy is built up in the form of a stream of coherent monochromatic light to allow for its escape. The intensity of the light increases after using fiber optics or mirrors to focus on the work area.

Inquiry

More Fiber Laser Cutting Machine