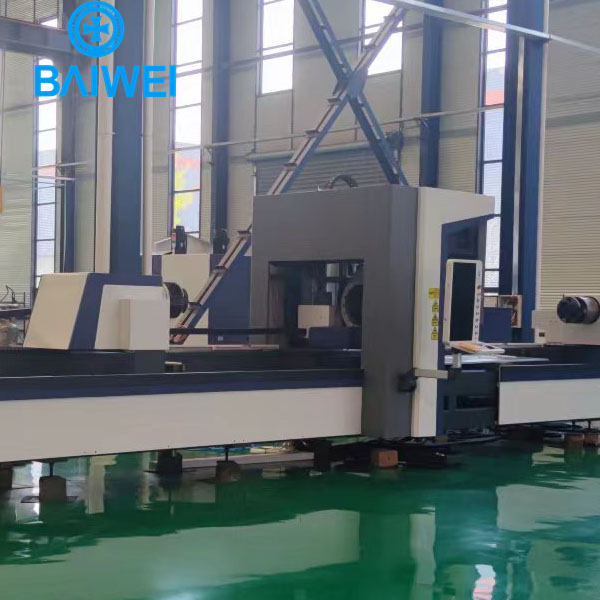

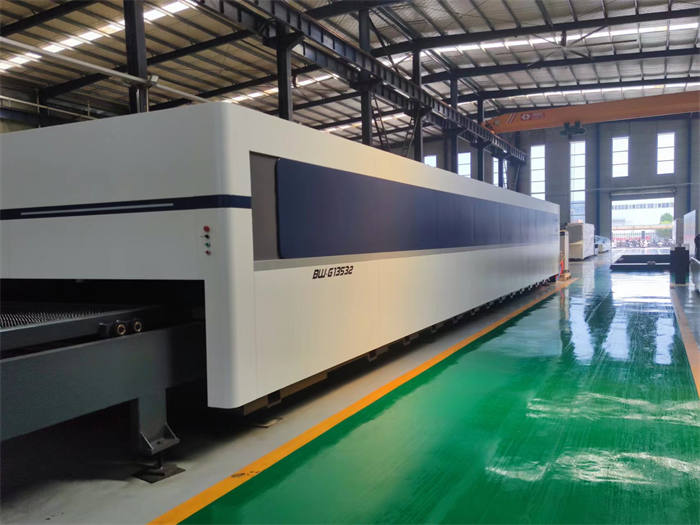

metal sheet CNC laser cutting machine manufacture

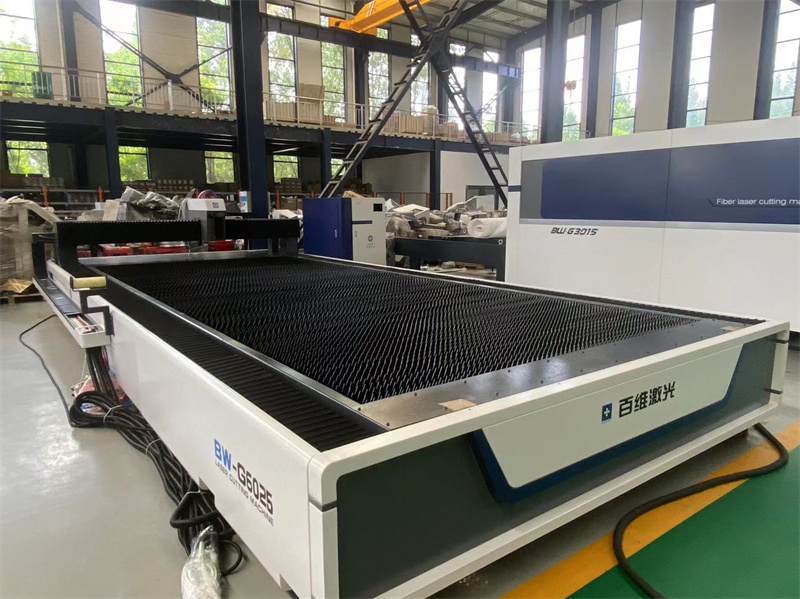

Model: BW-G6025

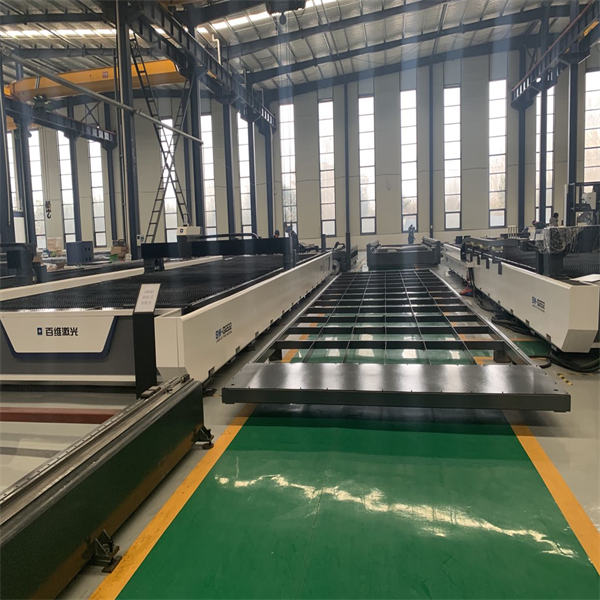

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

What are the advantages of fibre laser cutting machines?

The laser cutting machine is a non-contact photo-thermal process and is known as the “universal tool that never wears out”. The workpieces can be closely lined up or nested in any form so that the raw material is fully utilised. Cutting accuracy is high and thermal deformation is low. Because it is a non-contact process, there is no deformation of the machined workpiece and no need for secondary polishing.

The kerf of fibre laser cutting is very small, the kerf is generally between 0.15-0.4mm. The kerf is smooth and burr-free, and even finished transmission spur gears with a certain degree of accuracy can be machined directly.

Fibre laser cutting does not require mould opening. It is particularly suitable for the processing of multi-species and small batch sheet metal parts in the new product development stage, which can save high mould design and manufacturing costs and greatly shorten the production cycle. The laser cutting machine is low cost of use, requiring only basic electricity and auxiliary gas costs. Environmentally friendly, no noise, no pollution to the surrounding environment