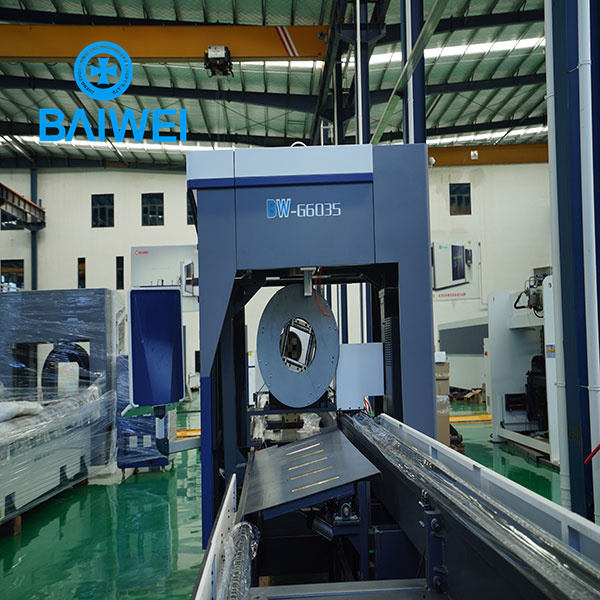

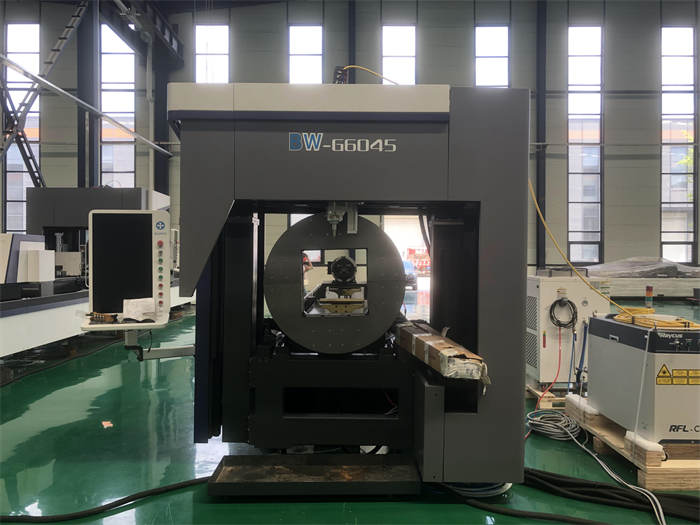

Metal cutting industry Cnc Laser tube Manufacture

For some porous workpieces, use the dot function of the laser pipe cutting machine to determine the position of the hole, which saves the time for positioning the hole and the manufacturing cost of the drilling template in the subsequent drilling process, which not only improves the production efficiency, but also improves the quality of the product. precision. Model:BWQG6016-6000*160 professional tube laser cutting machine

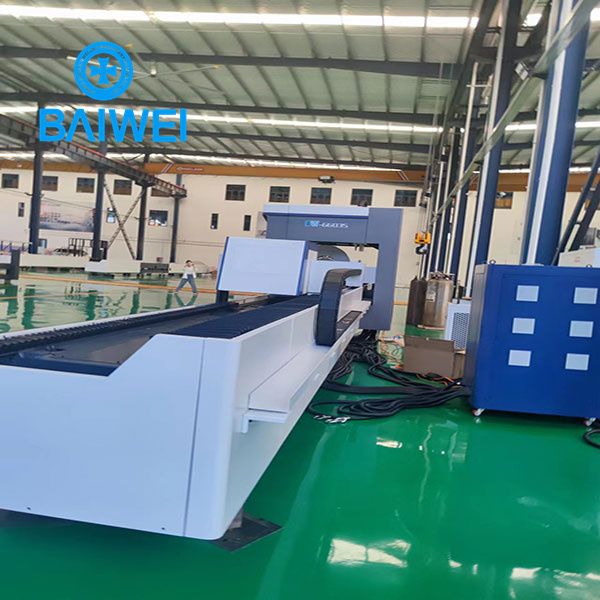

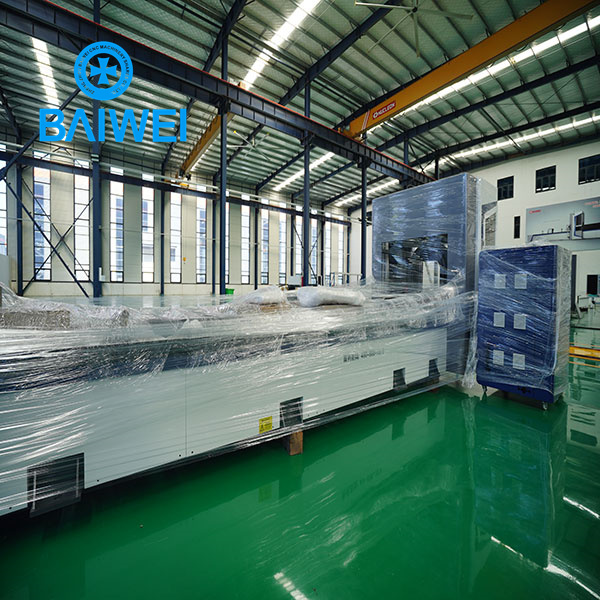

Power:3kw/4kw/6kw/8kw

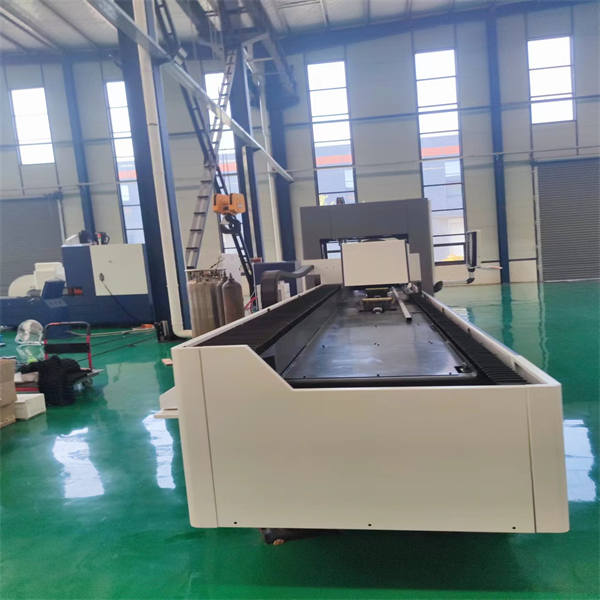

Cutting diameter: ¡Ü499mm

Cutting length: 6000mm/9000mm/12000mm

Baiwei laser processing can use modern computer-aided design/computer-aided manufacturing software to cut various shapes of plates. Using laser processing not only has high processing speed, high efficiency and low cost, but also does not need to change molds or tools, thus shortening the production preparation time. It is easy to realize continuous processing, the laser beam transposition time is short, and the production efficiency is high. Various workpieces can be mounted alternately. When processing workpieces, the finished parts can be taken out, and the workpieces to be processed can be installed to realize parallel processing.