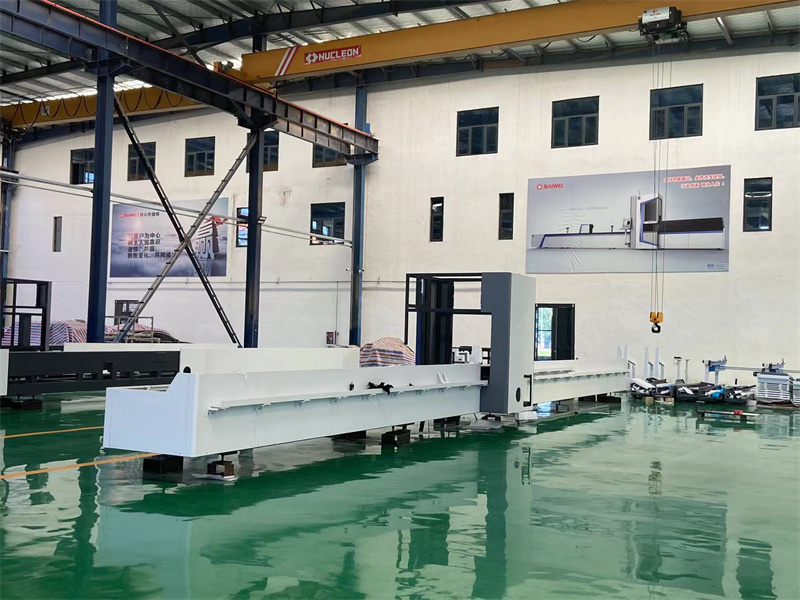

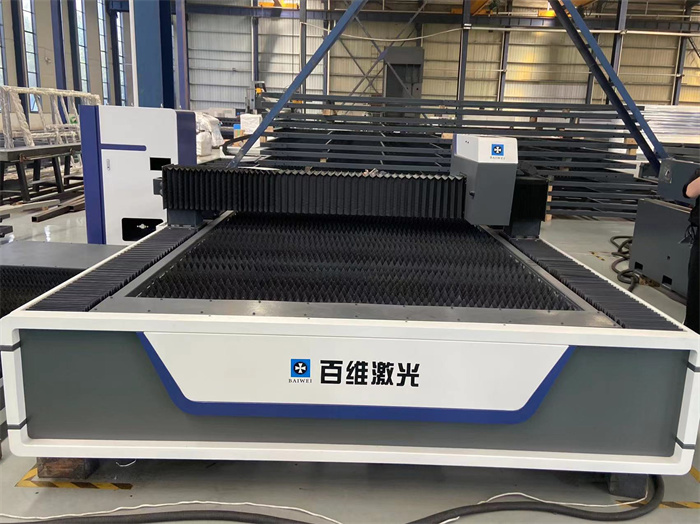

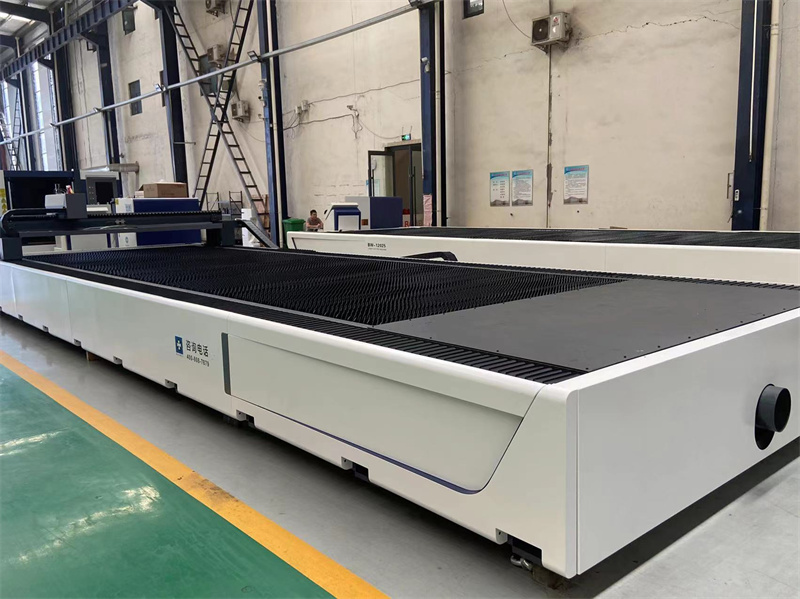

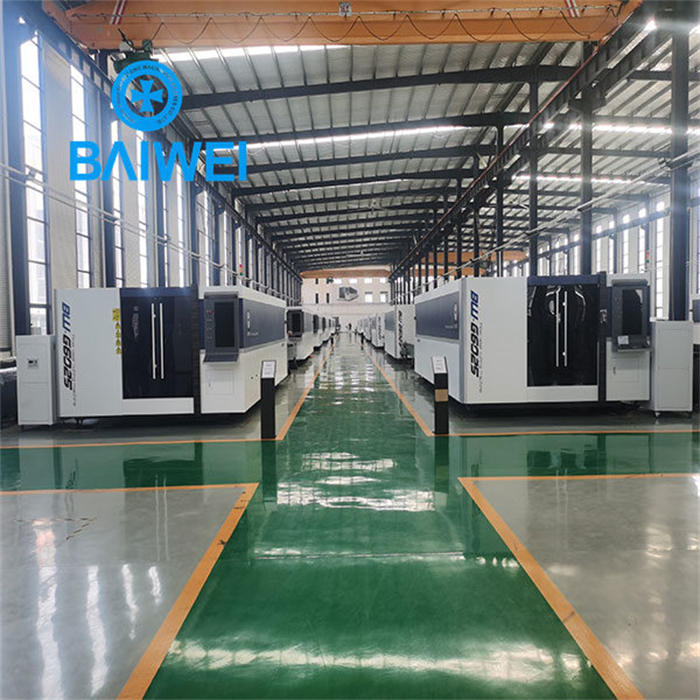

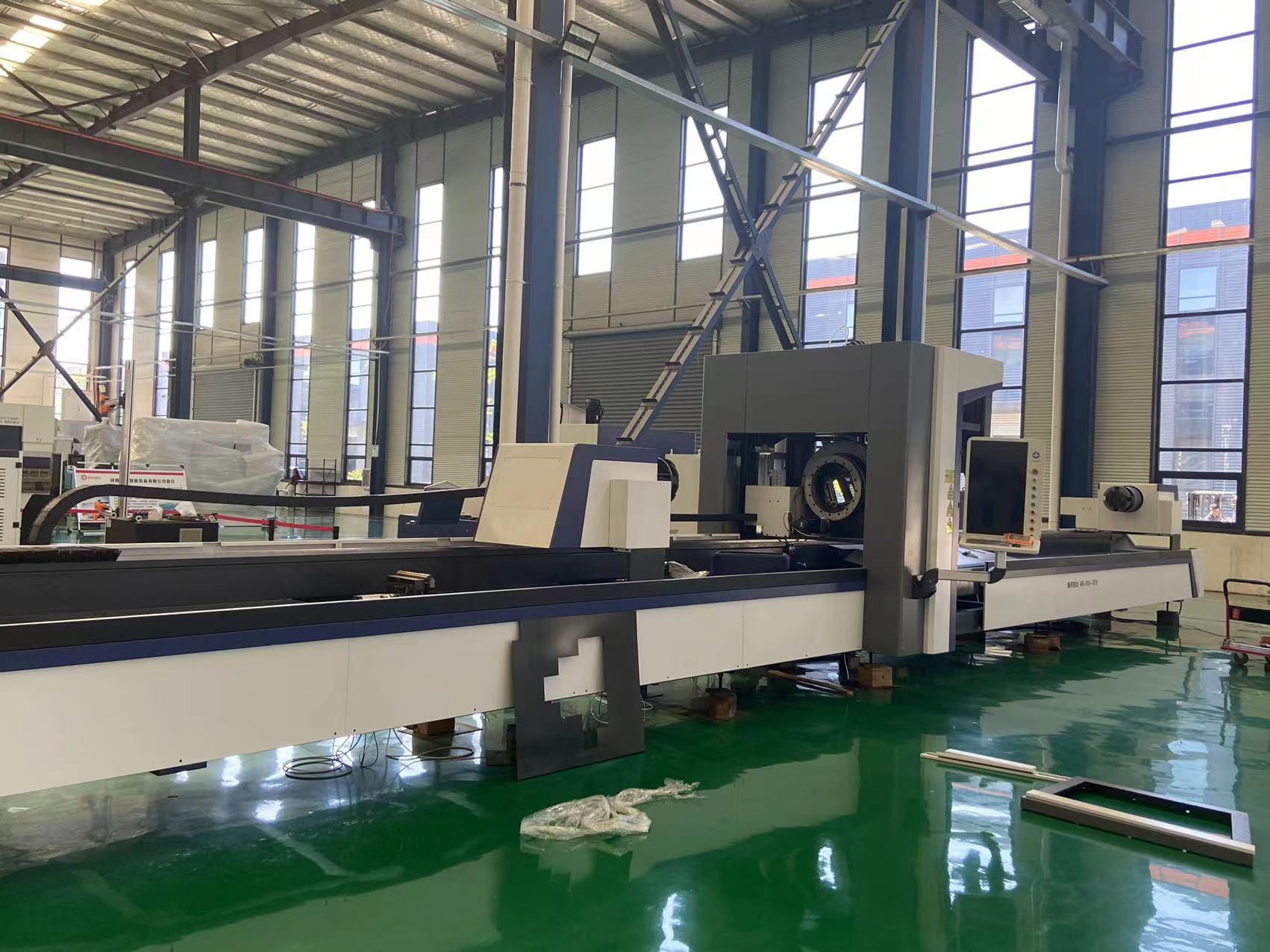

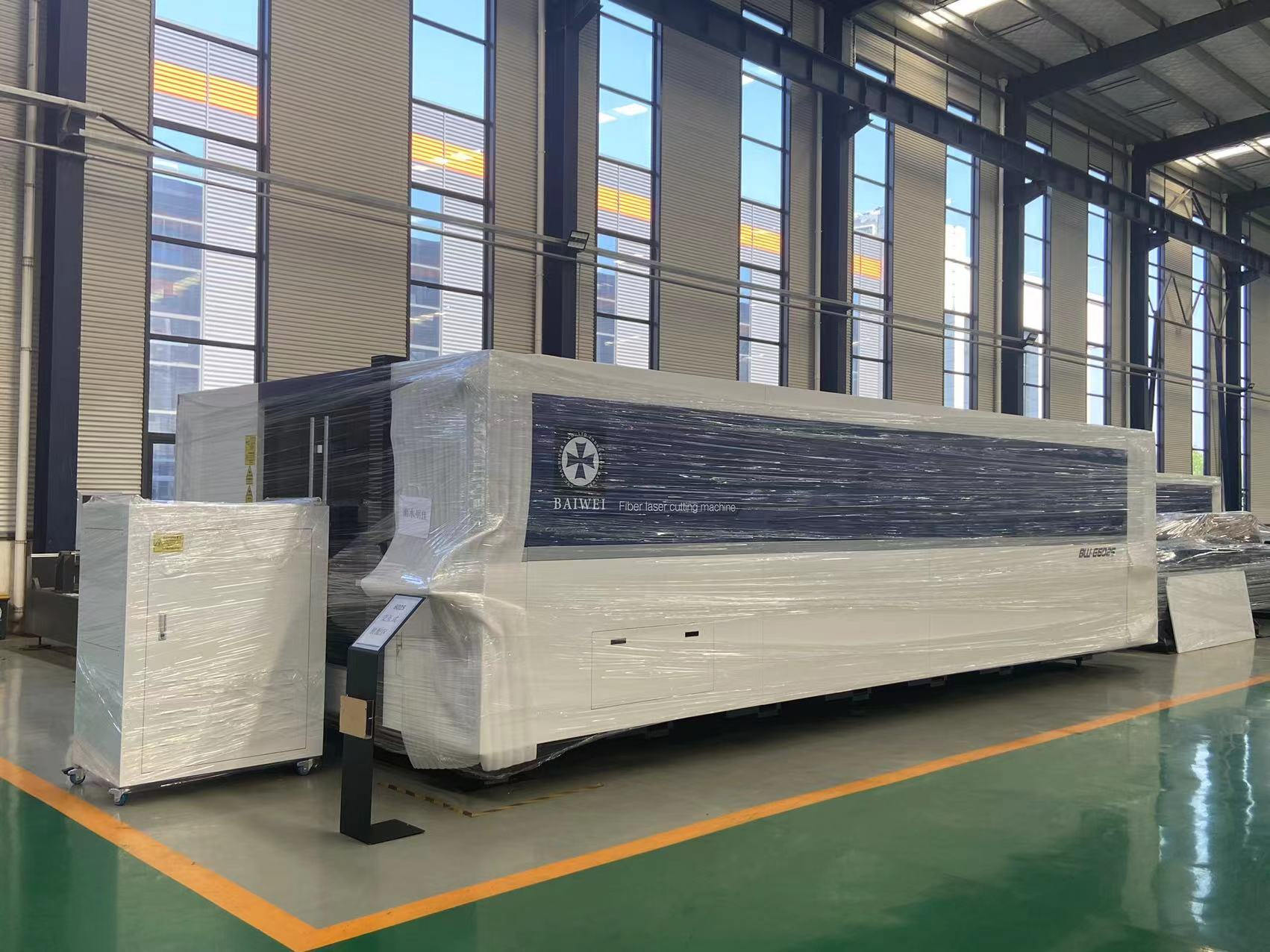

Massive closed type fiber laser cutting machine for aluminum plate

The closed fiber laser cutting machine has good cutting quality and adopts non-contact cutting. Therefore, the cutting edge of the closed fiber laser cutting machine is little affected by heat, and there is basically no thermal deformation of the workpiece.

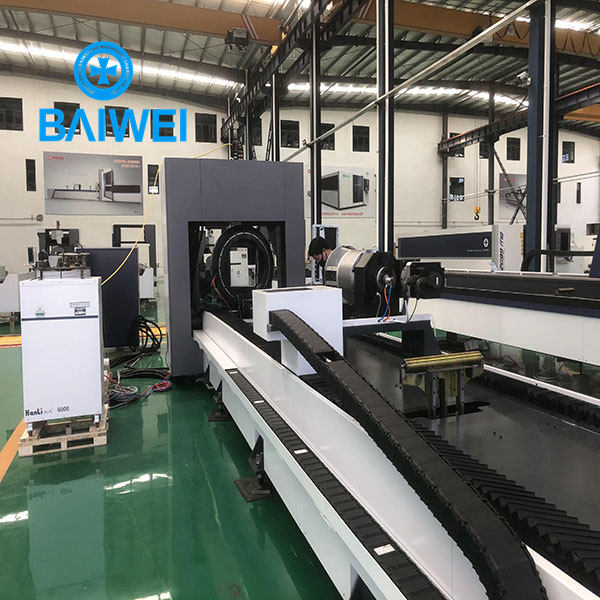

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

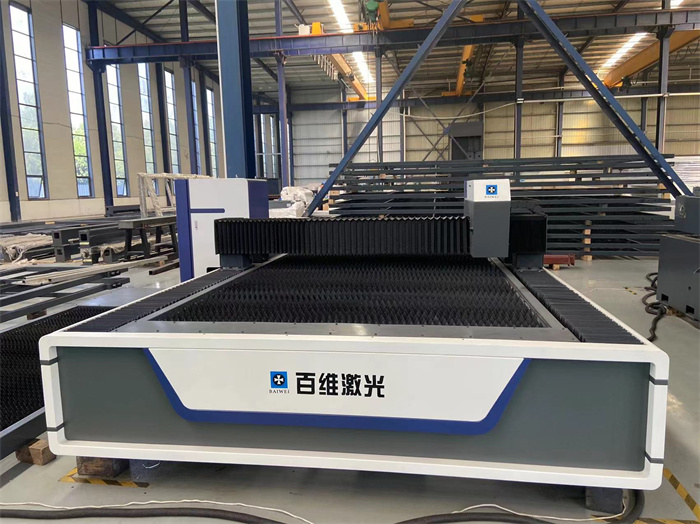

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

Why is the laser cutting machine better than other cutting machines?

There are a lot of different ways to cut material; rotary knife, vibrating knife, punch presses, shears, water-jet, EDM (Electrical Discharge Machining), plasma, oxy-acetyline, dedicated presses for long run manufacture as well as laser. Laser has some advantages in specific materials, but is no substitute for everything. Plasma is now the go-to cutter for small machine shops because of it¡¯s versatility. Water-jet is no.1 choice for difficult and abrasive materials that are cheap to make. EDM is probably the most accurate and is able to cut materials that are impossible for other technologies. It is capable of cutting super accurate blind holes of any shape. Clothing people don¡¯t want a laser cutter when a vibrating knife is capable of cutting multiple layers of flammable material. So laser-cutting isn¡¯t the best cutting system. Just one of many tools in modern industry that does specific jobs cheaply, accurately and quickly.