Main application of intelligent flexible bending machine center

Maximum bending speed: 0.2 second/shot

Maximum bending width: 1400mm

Bending height:About 170mm(customizable)

The rated voltage:380V

Peak power:about 18KW

Average power:about 1.8KW

The noise:about 50 decibels

Dimensions:440cm*190cm*290cm

The total quality:about12tons

Maximum beding thicknessUTS 515N/mm2 201stainless steel 0.8mm

(standard) UTS 520N/mm2 304stainless steel 1.0mm

(Optional thickness) UTS 410N/mm2 304cold plate 1.2mm

UTS 265N/mm2 304Aluminum plate 1.6mm

Minimum material thickness:about0.35mm

Minimum inner dimensions:about140mm*190mm

Minimum inner size:about140mm

Minimum bending size:about1400mm*1400mm

Number of shaf:standard 13axis concurrent linkage

Conventional hinge cutter:(option)

Power hinge cutter:(option)

filing cabinet area

Filing cabinet laminate can be bent once with simple programming.

The flexible CNC bending machine is used to bend the four sides of the cabinet laminate.

The filling cabinet automatically tilts and forms a large polygonal bend.

door industry

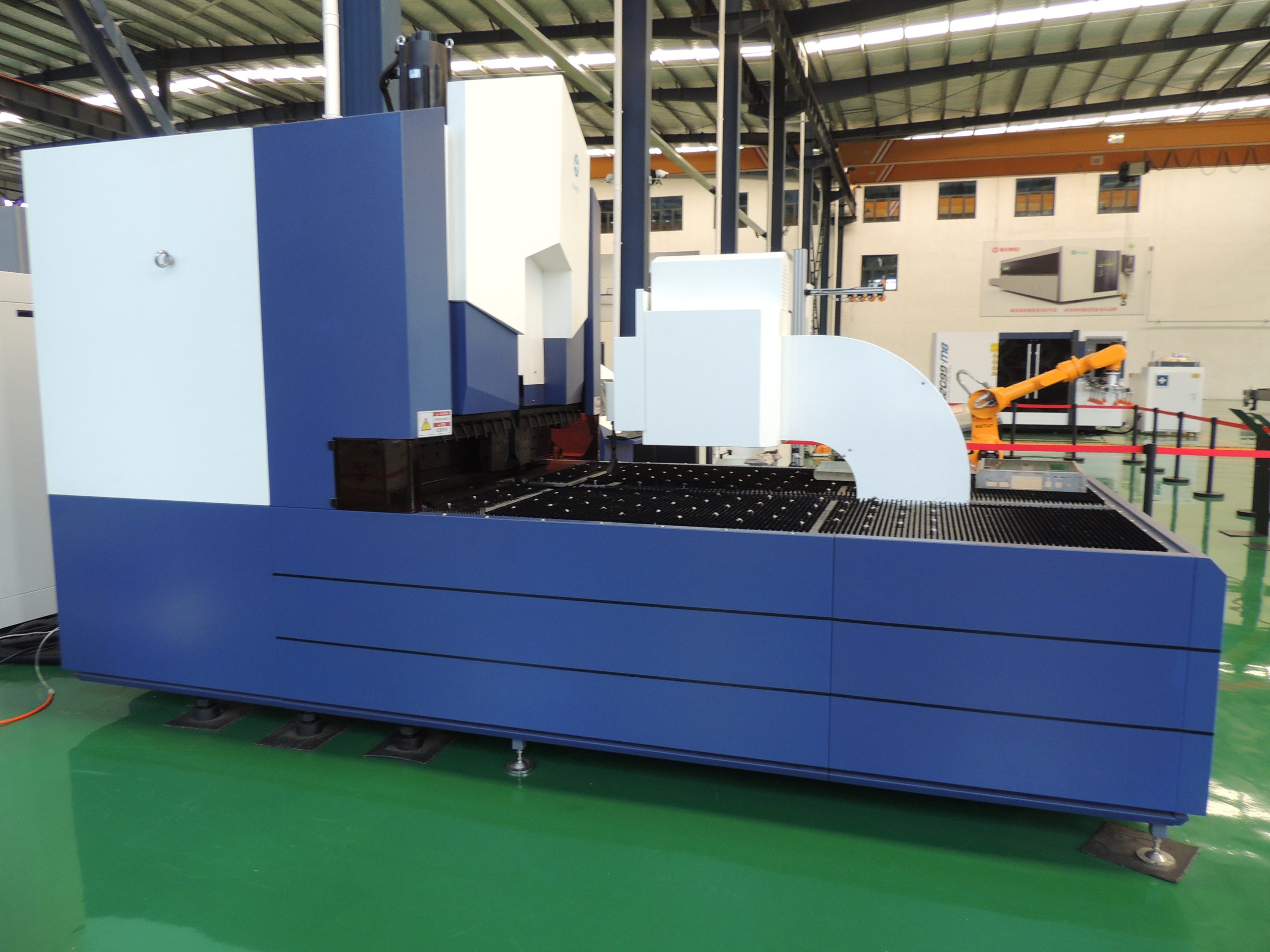

Prima Flexible Bending Center bending machines are designed to solve a wide variety of complex bending problems in sheet metal and metal forming. Through multi-axis parallel connection, the sheet metal operation is automatically completed, and the dependence on molds and labor is solved from a technical point of view, effectively improving production efficiency and reducing production costs.

Easily meet complex sheet metal bending requirements such as arcs, dead edges, return strokes, and closures.

Prima Flexible Bending Center folding machine steel cabinet shell (file cabinets, tool cabinets, exterior panels, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets…), kitchen appliances (refrigerators, air conditioners, stoves…), Furniture, ventilation, refrigeration, cleaning, door industry, decoration, elevator and other related metal forming fields.

complex bending

Prima Flexible Bending Center bending machines are designed to solve a wide variety of complex bending problems in sheet metal and metal forming. Through multi-axis parallel connection, the sheet metal operation is automatically completed, and the dependence on molds and labor is solved from a technical point of view, effectively improving production efficiency and reducing production costs.

Easily meet complex sheet metal bending requirements such as arcs, dead edges, return strokes, and closures.

Prima Flexible Bending Center folding machine steel cabinet shell (file cabinets, tool cabinets, exterior panels, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets…), kitchen appliances (refrigerators, air conditioners, stoves…), Furniture, ventilation, refrigeration, cleaning, door industry, decoration, elevator and other related metal forming fields.

lighting area

Prima Flexible Bending Center bending machines are designed to solve a wide variety of complex bending problems in sheet metal and metal forming. Through multi-axis parallel connection, the sheet metal operation is automatically completed, and the dependence on molds and labor is solved from a technical point of view, effectively improving production efficiency and reducing production costs.

Easily meet complex sheet metal bending requirements such as arcs, dead edges, return strokes, and closures.

Prima Flexible Bending Center folding machine steel cabinet shell (file cabinets, tool cabinets, exterior panels, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets…), kitchen appliances (refrigerators, air conditioners, stoves…), Furniture, ventilation, refrigeration, cleaning, door industry, decoration, elevator and other related metal forming fields.

electric field

The electric field flexible bending machine can automatically adapt to different geometric shapes and realize mass production. Both softness and high performance, automatic bending processing

kitchen area

Kitchenware sheet metal bending, large kitchen sink bending, multi-faceted metal bending.

The domestic flexible bending machine PM2500 is a high-end servo flexible bending center folding machine developed by Prima Intelligent Equipment Technology Research and Development Department after two years of technical research. The bending speed is only 0.2 seconds per tool. The equipment can automatically perform combined bending of circular arcs, dead edges and various angles according to the bending process, and can meet different bending requirements without changing bending tools, saving a lot of labor and mold costs for enterprises.