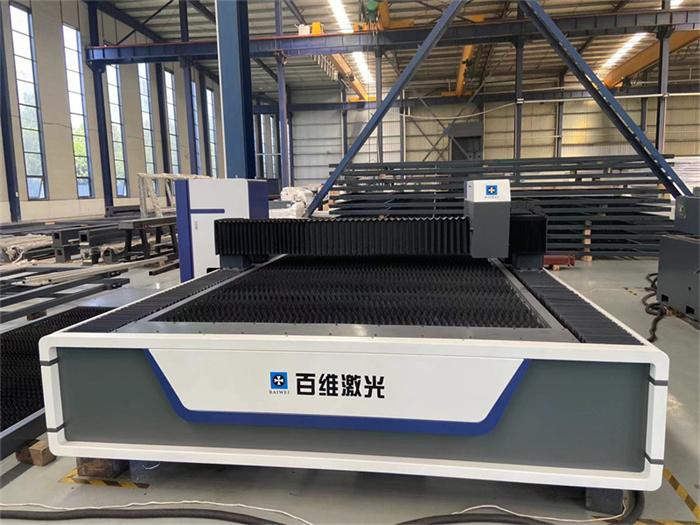

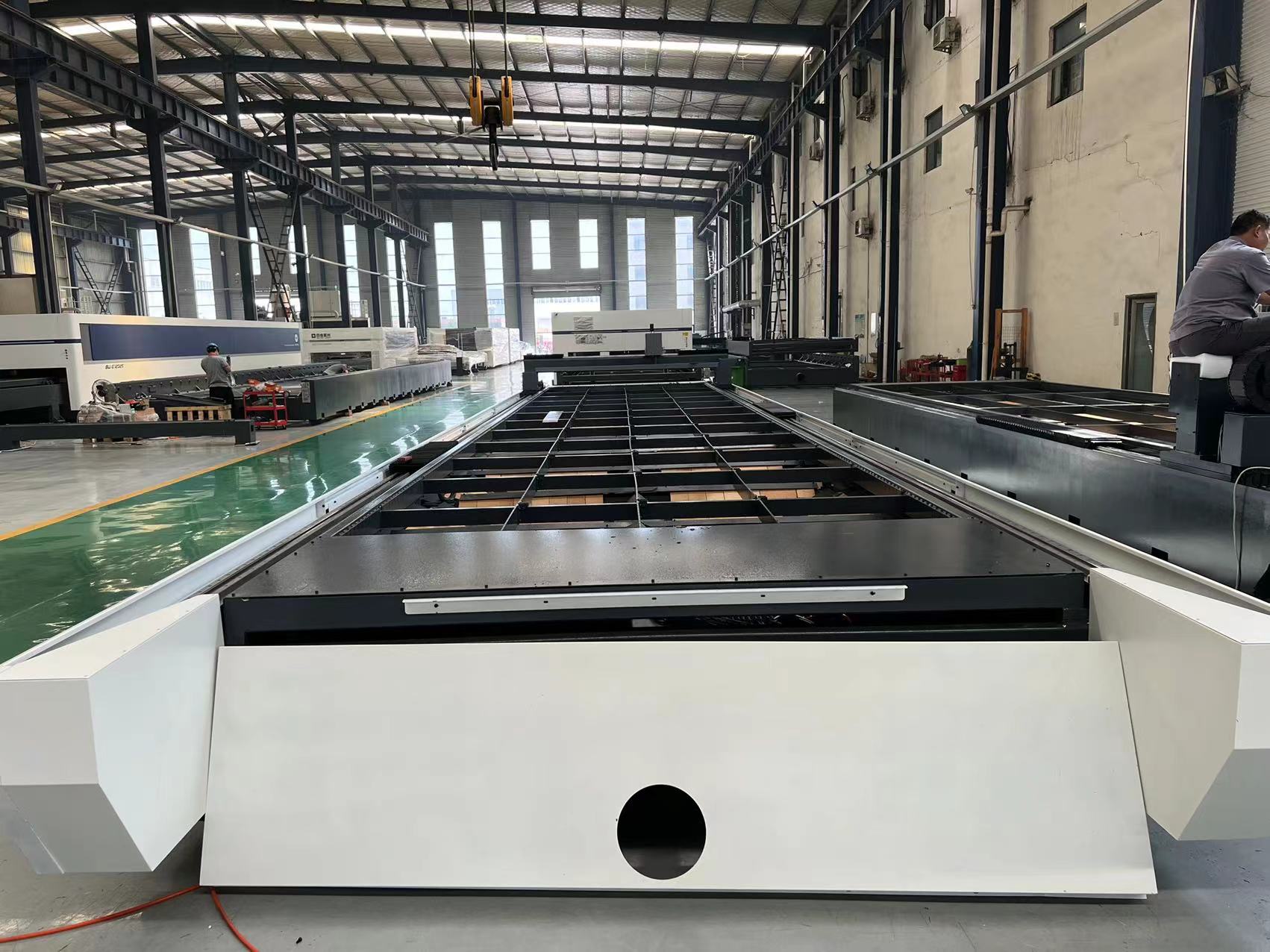

Laser pipe cutting machine, brand new cast iron bed, high-precision energy-saving and high-efficiency equipment

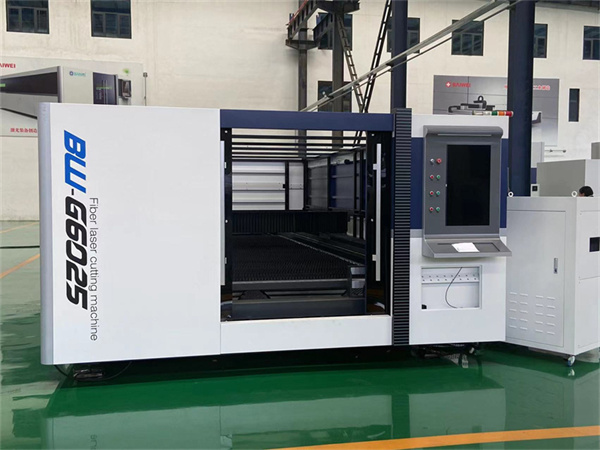

Parameter

Model BW3000/BW6000/BW9000

Laser Generator Medium Fiber Laser Source

Output Power 3000W/4000W/6000W/8000W/12000W

Effective pipe cutting diameter 15-220mm

Working axial positioning accuracy <±0.05mm

Worktable reposition accuracy <±0.02mm

Advantages of Laser Tube Cutting Machines

1. Flexibility

The fiber laser tube cutting machine can cut any pattern on the metal tube, and the laser can cut in any direction and angle, which provides a strong and favorable technical support for more and more personalized processing, and the first cutting does not need to be opened. mold, reducing the cost of the first mold opening of traditional equipment

2. Accuracy

Compared with traditional processing equipment such as flame cutting, plasma cutting and water cutting, laser cutting metal materials is much more precise. At the same time, different materials may have small expansion and contraction deformation during the processing process, and the laser pipe cutting machine can be flexibly adjusted according to these deformations, which cannot be achieved by many traditional processes.

Fiber laser pipe cutting machine is specially designed for pipe processing customers and fills the gap of pipe processing technology in China. Convenient operation, high degree of automation, fast cutting speed and high precision, meet the needs of large-scale industrial production, and have become the first choice for the equipment pipeline processing industry. It has been successfully used in various metal pipeline processing industries such as fitness equipment, agricultural machinery, residential pipelines, construction machinery, vehicle manufacturing, special vehicles, and electrical equipment manufacturing.

Powerful cutting function, can cut square tube, round tube, rectangular tube and various special-shaped tubes. Adopt rack drive structure, pneumatic clamping chuck, rotary push tube cutting method, high centering accuracy and high machining accuracy. After annealing to eliminate internal stress, the machine tool is completed, the stress generated by welding and processing is solved, and the rigidity and stability of the equipment are improved. Better stability and longer service life. Excellent processing system, friendly interface, convenient operation, real-time feedback of processing status, ensure the orderly progress of processing