Laser cutting conditions for steel plates having a thickness of more than 100 mm using a 30 kW fiber laser

Parameter

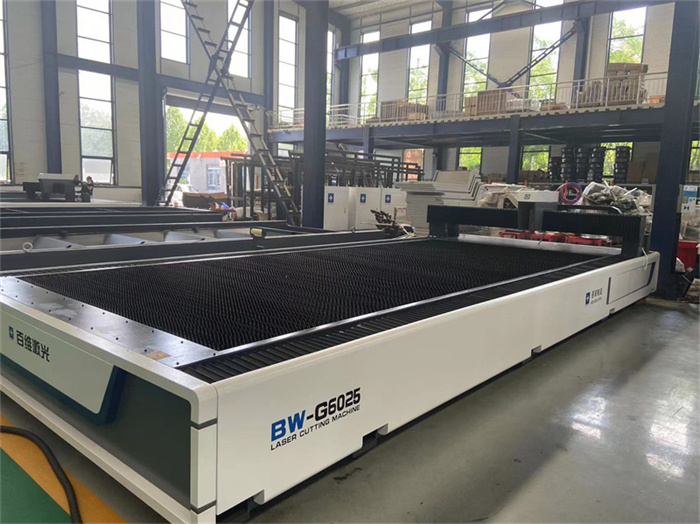

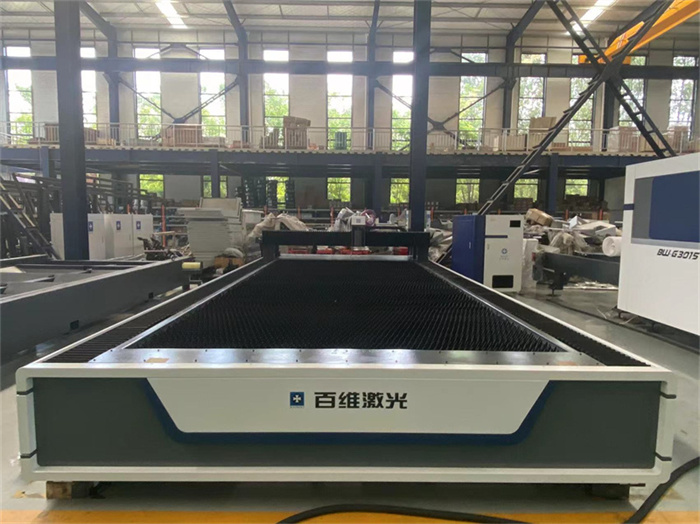

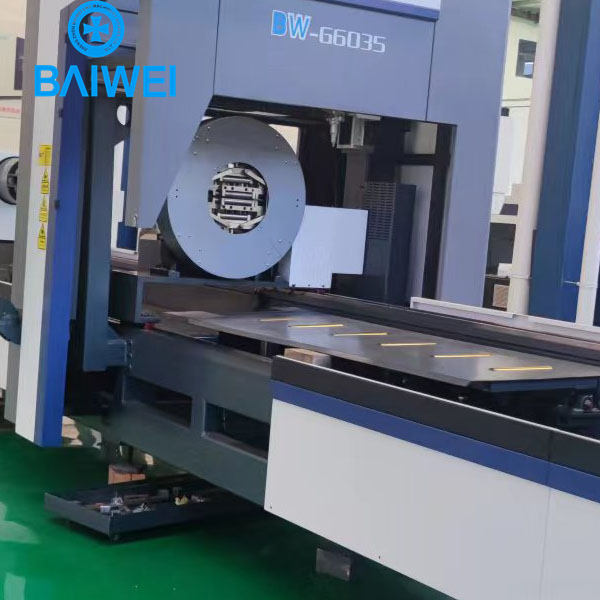

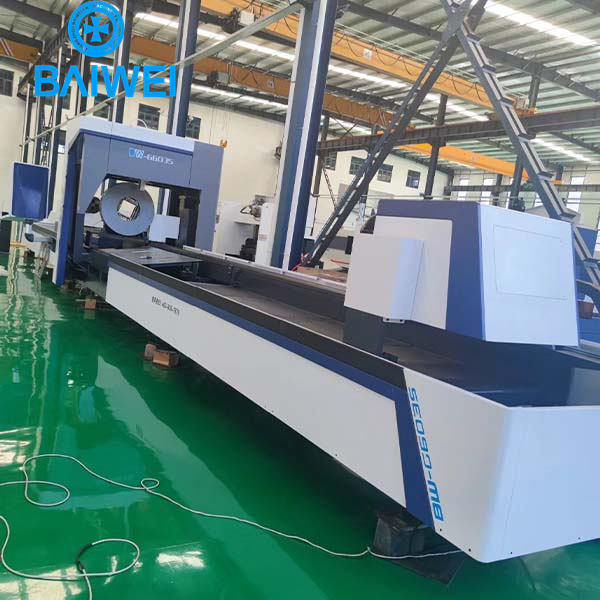

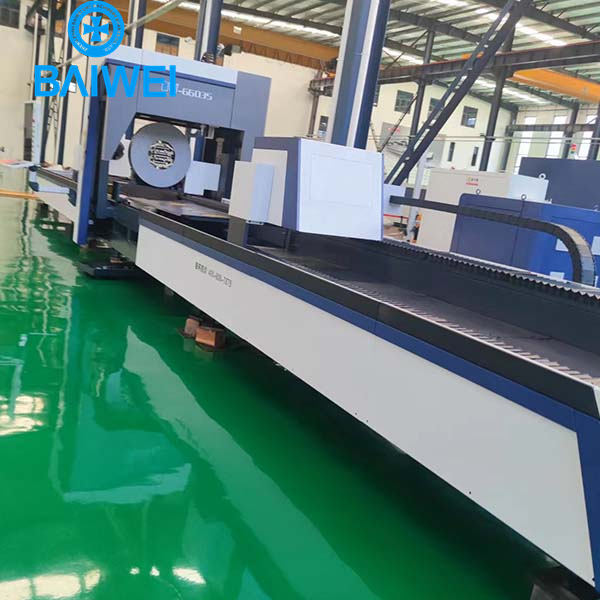

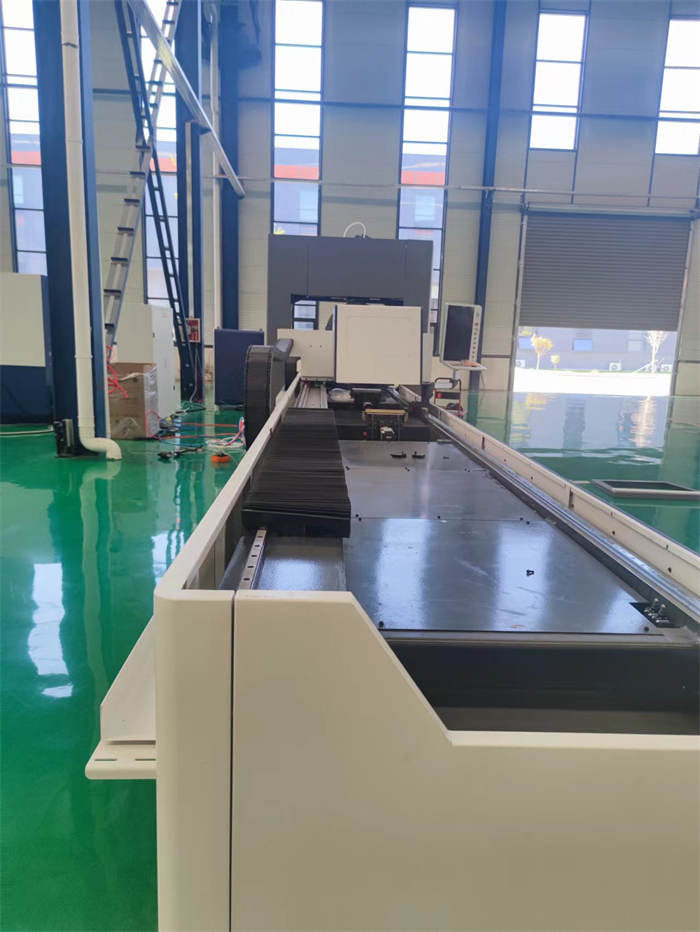

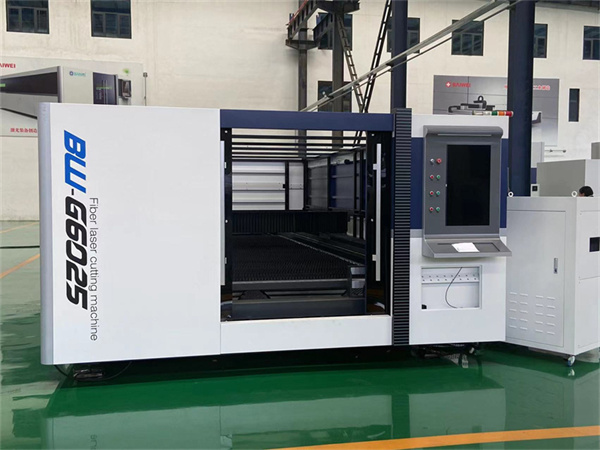

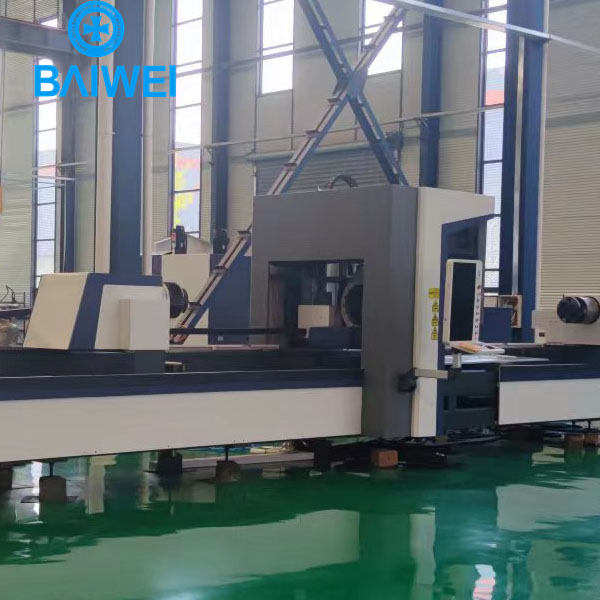

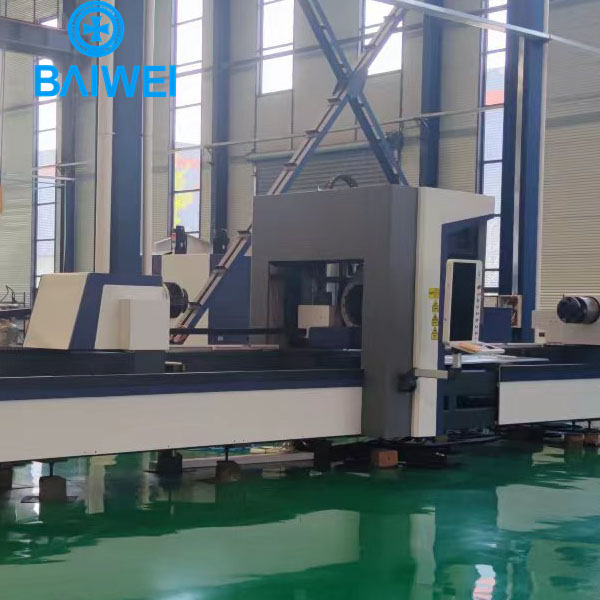

Models BW3000 BW6000 BW9000 BW12000

Cutting length 3000mm 6000mm 9000mm 12000mm

Laser power 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw

Effective tube cutting diameter 15-220mm

Worktable axial positioning accuracy <±0.05mm

Workable reposition accuracy <±0.02mm

Laser cutting conditions for steel plates having a thickness of more than 100 mm using a 30kW fiber laser were studied for the application to the nuclear decommissioning. Specimens of carbon steel and stainless steel plates were irradiated by laser beam and assist gas. The observed kerf widths at the rear face of the plates were considerably enlarged compared with those at the front face with the increase of the plate thickness for both specimens, when the stand-off distance between nozzle tip of the laser head and the specimen surface was kept 5 mm. Both kerf widths became comparable when specimens were cut at a relatively larger stand-off distance, where the incident laser beam size at the front face of the specimen was enlarged because of the defocusing of the beam. The results were applicable to the thick plate cutting, and specimens of stainless steel and carbon steel having a thickness of more than 100 mm were successfully cut based on this setup. The results show that for a very thick plate, sufficiently large kerf width was required for the cutting which was used as a duct for a successful melt flow process. The results are informative for the development of the laser cutting technology, and show that the laser cutting technology is promising for the dismantlement of thick steel components for the nuclear decommissioning.