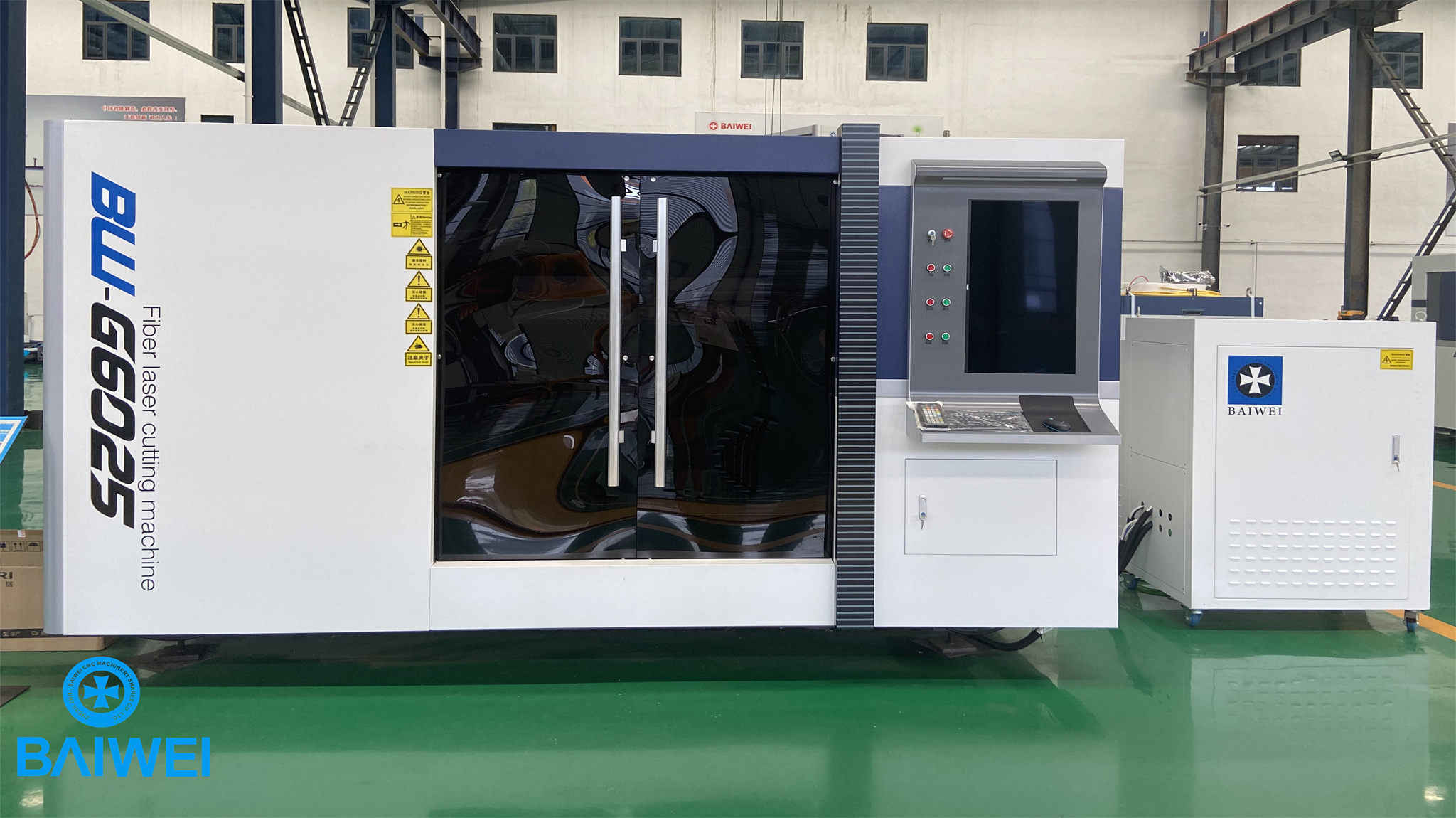

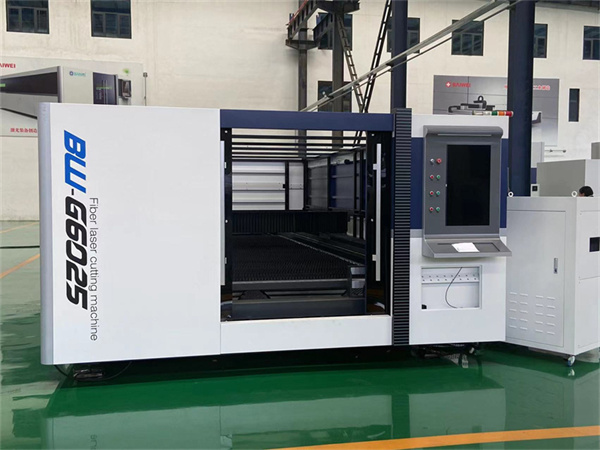

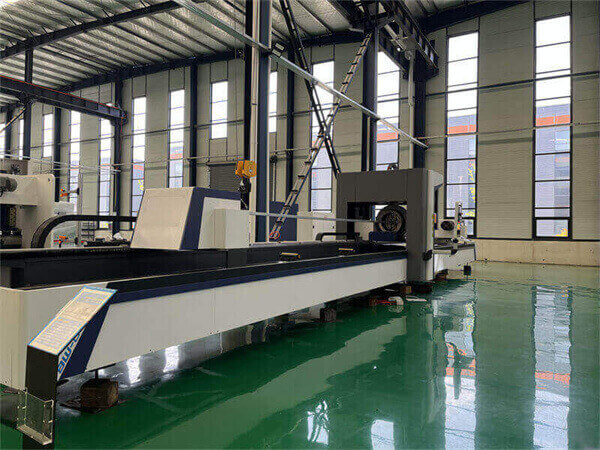

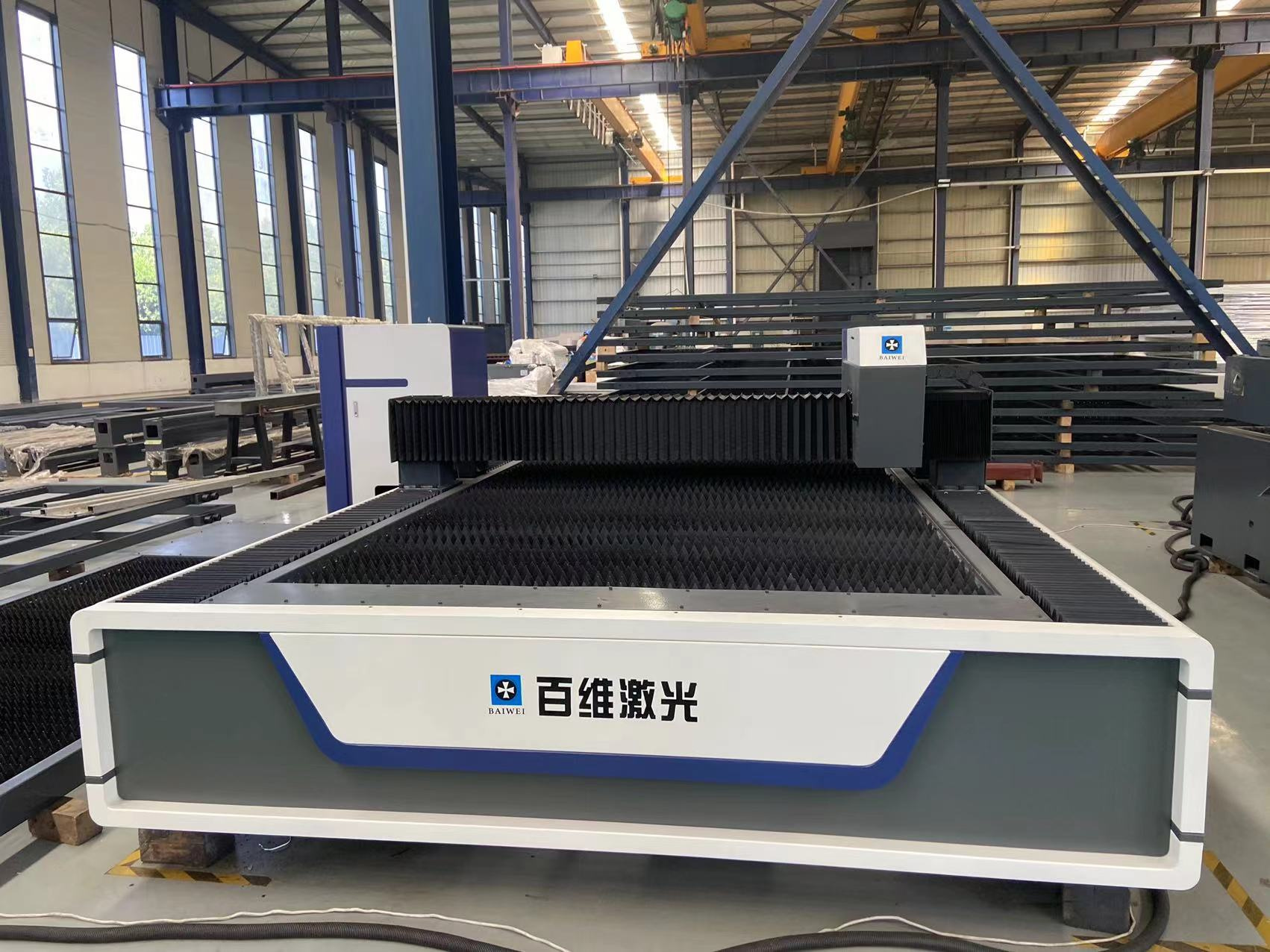

Large carbon steel closed type fiber laser cutting machine with factory Outlet

The closed type fiber laser cutting machine adopts an independent control cabinet, and the whole machine adopts a large enclosure design. Therefore, The closed type fiber laser cutting machine is not only dustproof and isolated, but also improves the life of electronic components.

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

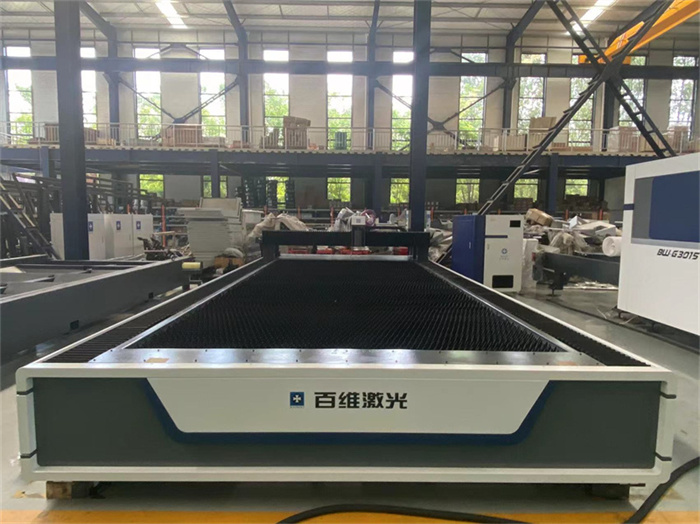

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

How should you protect your fiber laser cutting machine in winter?

If you own a fiber laser cutting machine, the final target of yours must be earn more by utilizing the machine without any accidents. However, there¡¯s a critical point should be remembered.

At first, you need to know that the fiber laser generator is fragile, you need to ensure the maintenance of this kind of key components. Our equipment could keep a normal condition with normal room temperature, but the water cooling machine would be broken if it stays at the super-low temperature. Accordingly, the water cooling machine couldn¡¯t work, which means that the laser generator will be burned caused by high temperature within the running process.

The best solution is to add some antifreeze into the water cooling machine before dropping temperature. And if you want to stop the equipment for a while, I suggest you to release water till there¡¯s no drop of water in the water cooling machine. And only in this way can you maintain the normal condition of machine.