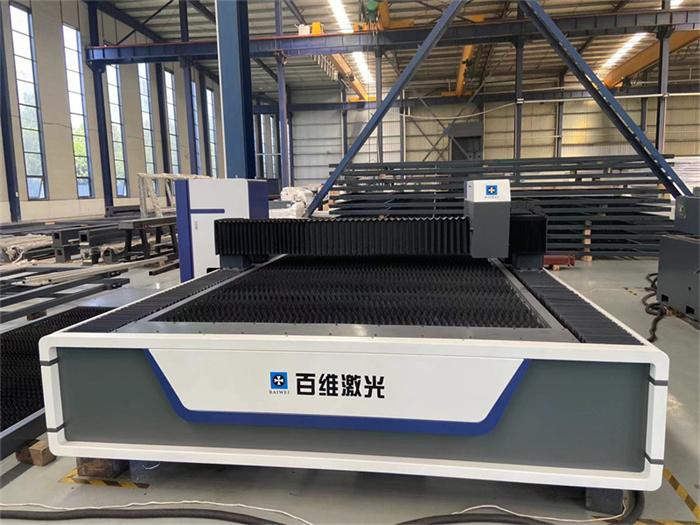

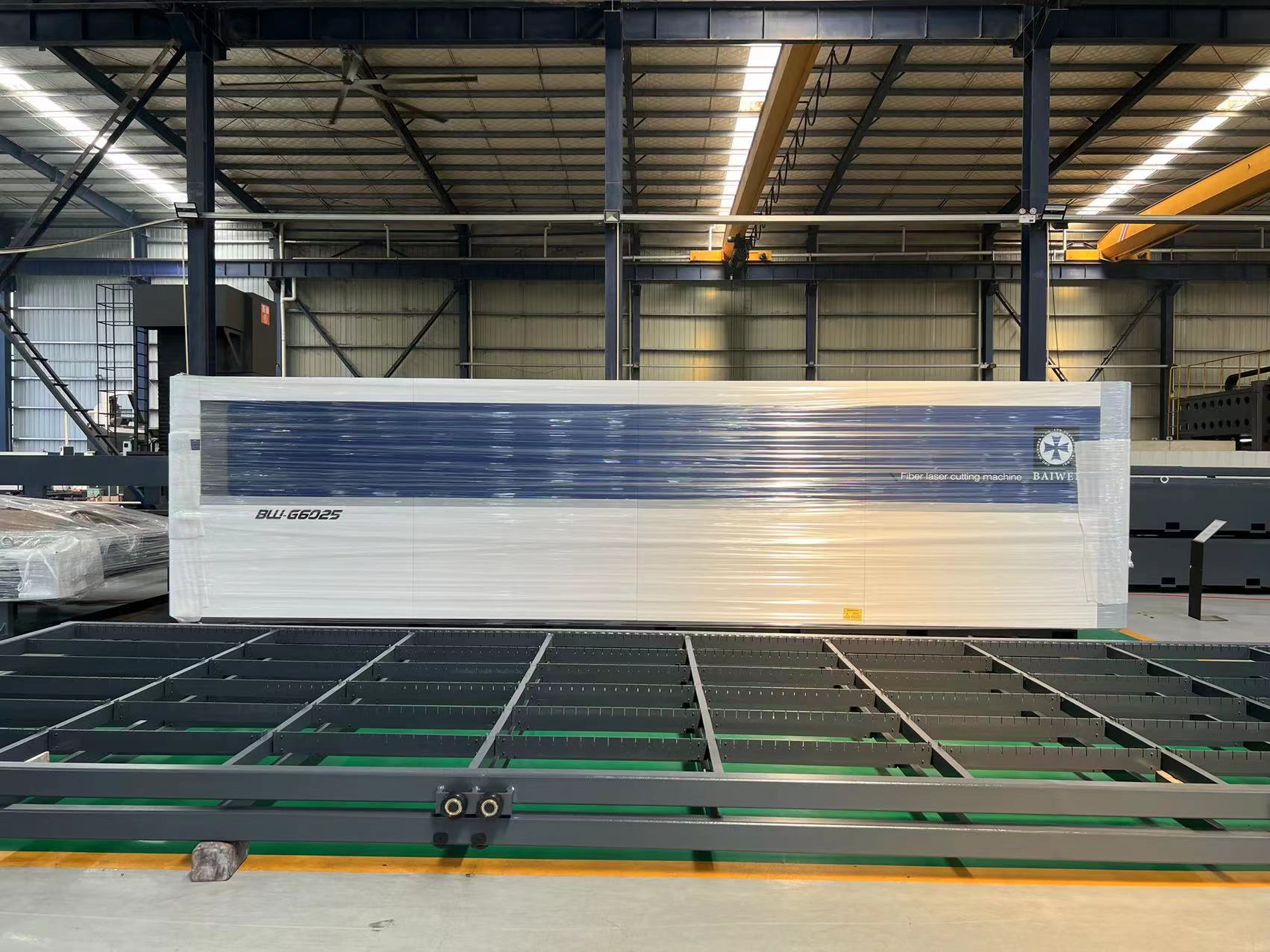

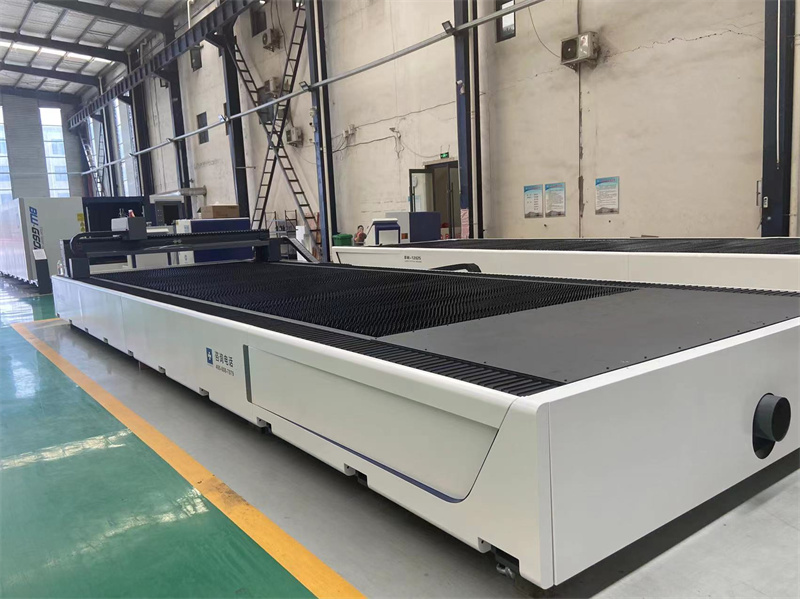

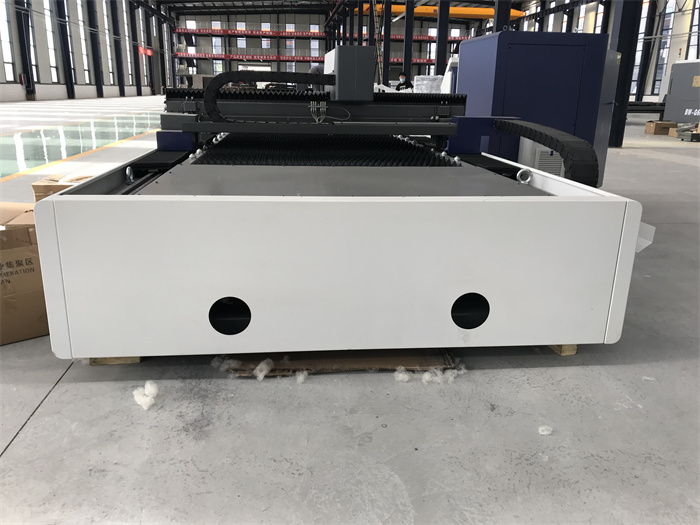

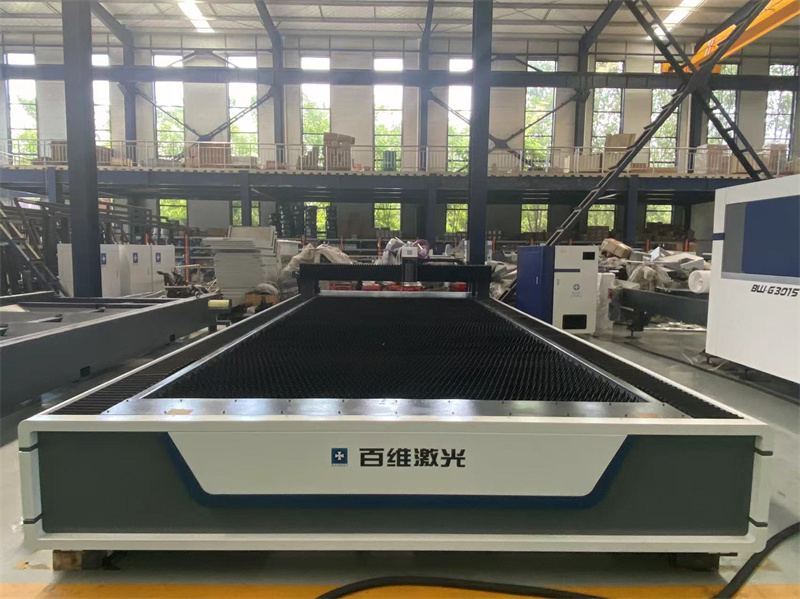

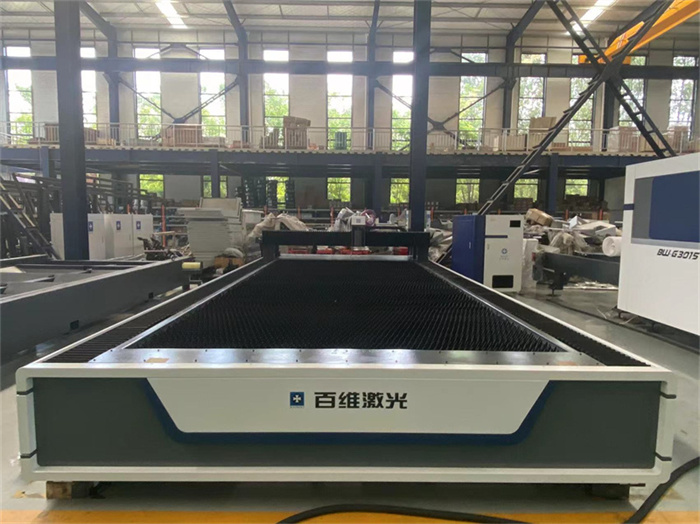

intelligent open type fiber laser cutting machine steel plate cutting

Model: BW-G3015

Cutting range: 3000x1500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 100m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

How do I maintain a fiber laser cutter?

1. Check the Machine Tool Every Day

1) Before starting the machine, check the pressure of the working gas and cutting gas of the laser. If the pressure is not enough, it needs to be replaced in time.

2) Check whether the buttons of X-axis, Y-axis, Z-axis zero point and laser ready status are damaged.

3) Check the circulating water level in the chiller, if the water level is insufficient, add it in time.

4) Check whether there is any leakage in the external optical circulation waterway. If there is leakage, clean it up in time, otherwise it will affect the life of the optical lens.

5) After the daily work is completed, waste materials on the work site should be cleaned up in time to keep the site tidy. Open the drain valve of the air storage cylinder at the bottom of the air compressor to drain the water. After the waste water is drained, close the water valve. Then turn off the main power supply of the machine tool in turn according to the power-on sequence.