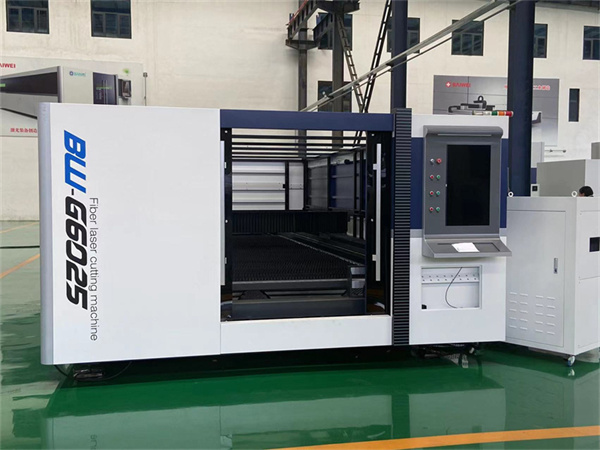

Industry carbon steel stainless aluminum pipe cutting machine / cnc fiber laser tube cutter equipment

Model BW3000/BW6000/BW9000

Laser Generator Medium Fiber Laser Source

Output Power 3000W/4000W/6000W/8000W/12000W

Effective pipe cutting diameter 15-220mm

Working axial positioning accuracy <±0.05mm

Worktable reposition accuracy <±0.02mmModel BW3000/BW6000/BW9000

Laser Generator Medium Fiber Laser Source

Output Power 3000W/4000W/6000W/8000W/12000W

Effective pipe cutting diameter 15-220mm

Working axial positioning accuracy <±0.05mm

Worktable reposition accuracy <±0.02mm

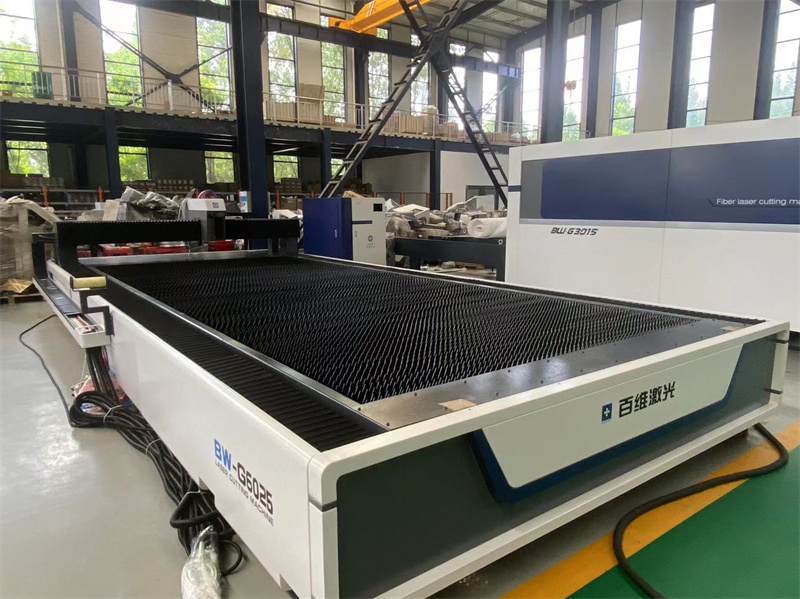

Simple maintenance

The frequency of use of machinery and equipment is relatively high at ordinary times, so it is necessary to carry out a simple maintenance of the laser cutting machine after a period of time, and the use effect of the machinery and equipment can be maintained through daily maintenance work. The maintenance of the laser cutting machine is relatively simple. There is no need to spend additional money on maintenance work. It only needs to help the equipment to drip lubricant for a fixed time.

low power consumption

The laser cutting machine used in the factory has to operate almost all day long. If a machine consumes a lot of power, it will increase the daily operating cost of the factory, which is also a lot of money. However, the regular laser cutting machine has relatively low power consumption, and it will not consume much power for a whole day, and the investment cost will be much lower.