How to choose the right model of fiber laser cutting machine?

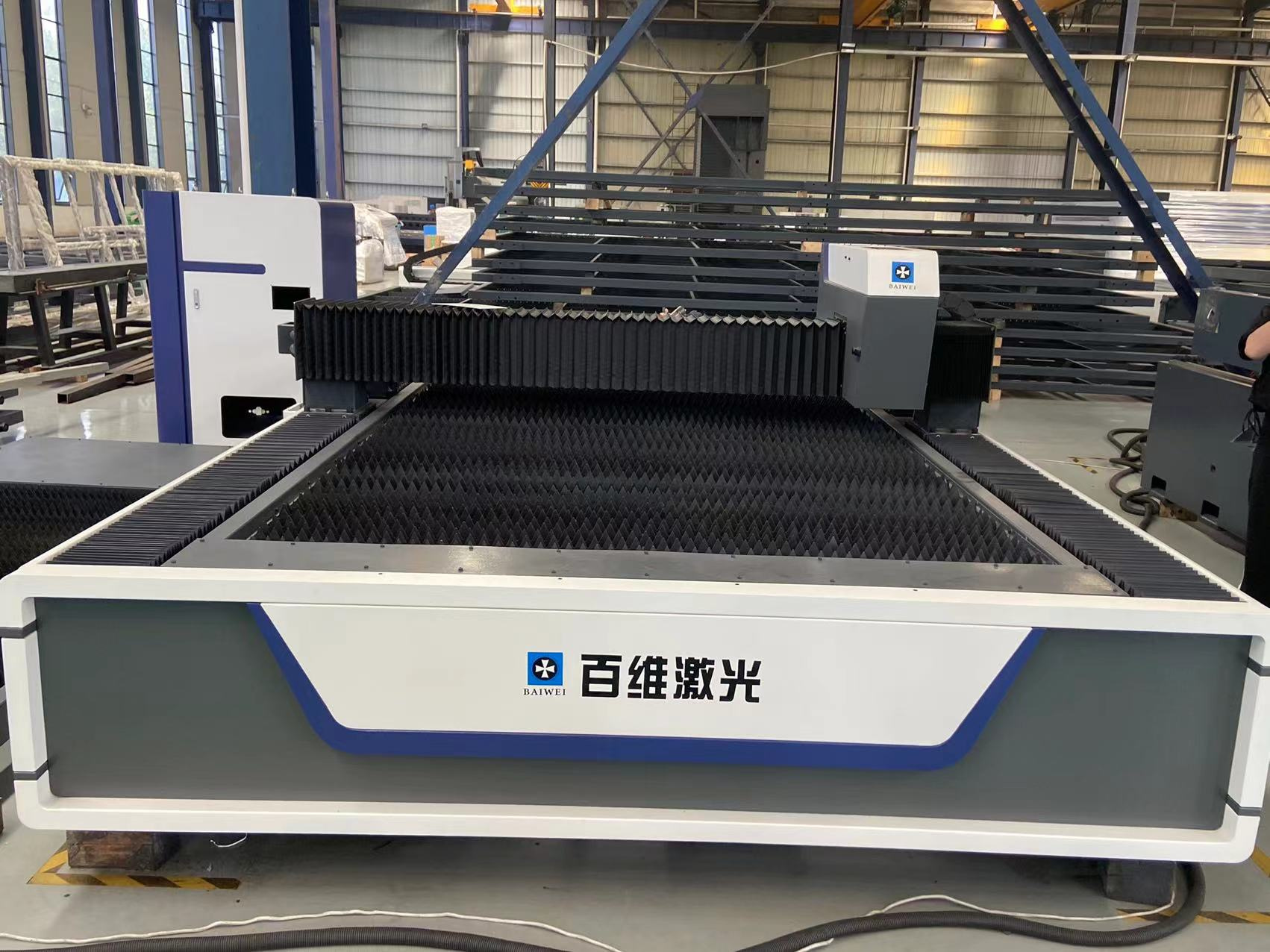

NO.1 Characteristics of our laser cutting machine

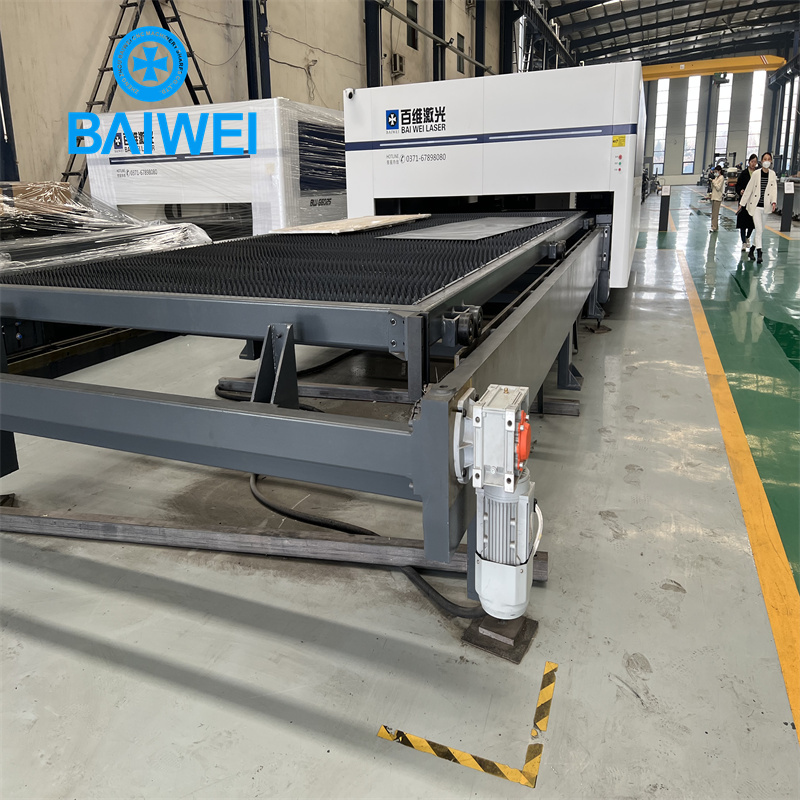

1. Application of heavy plate welding machine table after heat treatment to ensure it’s higher rigidity, stability, shock resistance.

2. High-performance laser source and stable operating system which make the best cutting effect.

3. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

4. The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

5. The machine is used for cutting a variety of metals with excellent and stable cutting quality.

6. The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

NO.2 Machine Application Field

1.Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2.Application Industries: Baiwei Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Do you know how to choose the right model of fiber laser cutting machine?

As you know, there are many different models of fiber laser cutting machine in this market. As a buyer, you need to learn three things first before you purchase this laser machine.

1.Capacity Power

Firstly, you need to learn which materials you need to cut? Mild steel, stainless steel or aluminum etc? And next you need to learn your maximum and often cutting thickness for each materials.

Choose the right capacity power is very important for you. Laser source market develop rapidly, with the laser source development,we suggest you at least consider 2kw when purchased this machine. For your using performance, it’s better leave space for your future need.

2.Application Area

According to the application area, our fiber laser cutting machine can be divided to three different models.

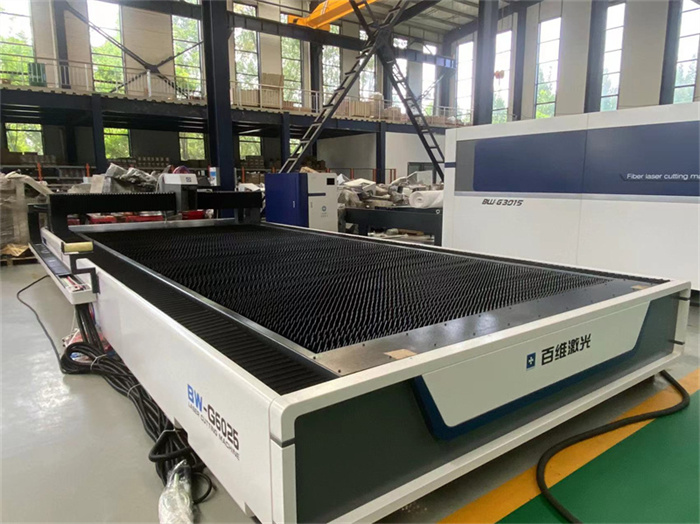

a.Flat fiber laser cutting machine, this model is focused on metal sheet cutting ,such as carbon steel, stainless steel,aluminum, copper, brass etc;

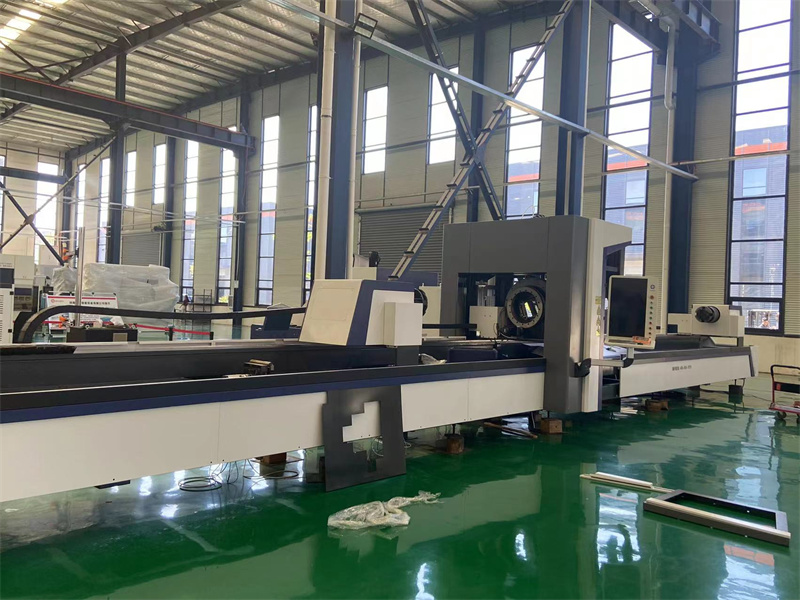

b.Pipe&Plate fiber laser cutting machine, this machine has two different functions, one machine which can cut both pipe and plate together;

c.Professional tube laser cutting machine, this model focused on tube cutting, especially we can customized the tube length, maximum length we can do is 12m; meanwhile,we can also customized the tube diameter, the maximum tube diameter we can do is 500mm.

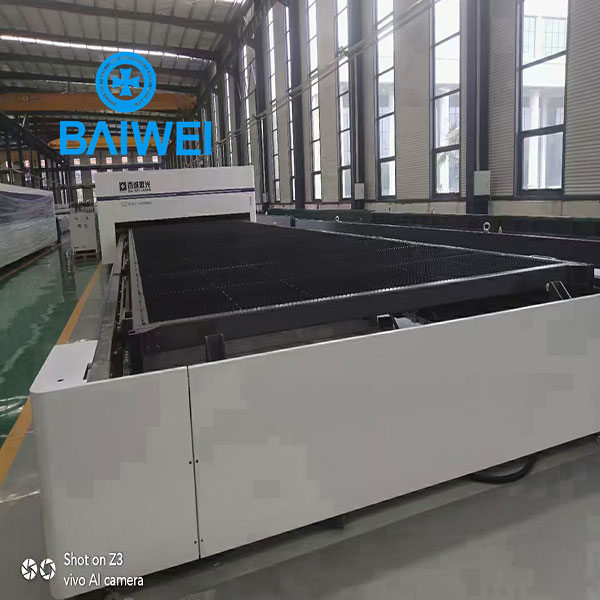

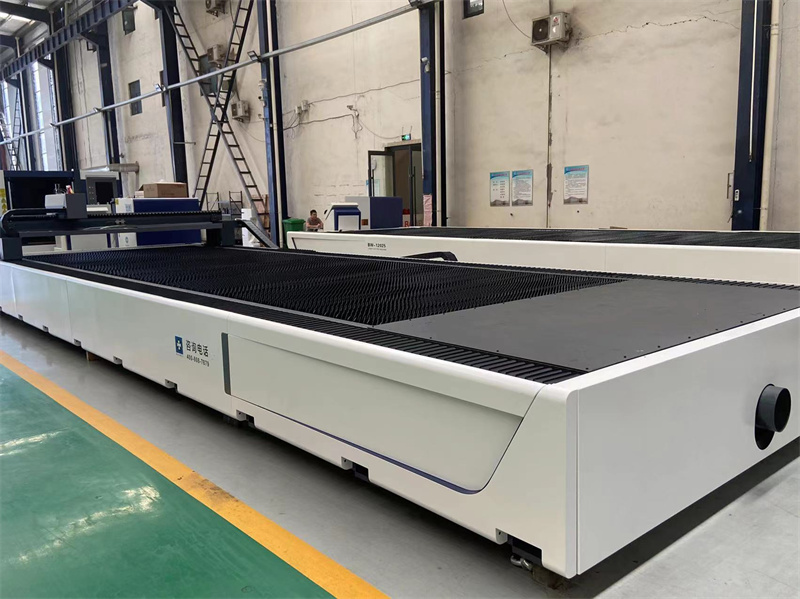

3.Model (Open type& closed type with exchange table)

Open type is with single table, so it takes less space, during transport time, we can use a 20GP. In this way, we can help you save ocean freight cost

Enclosed type with exchange table, this fully enclosed model has double table, so it can save loading and uploading time. Meanwhile, it’s more safe and environmental friendly.

As the ocean freight cost is extremely expensive, for help our customer save cost, our enclosed type can take apart to fit in a 40GP.

My dear friend, if you still have doubts and don’t know how to choose the right model, please feel free to contact with our sales engineer. We’re very glad to provide service for you!