How to choose power of a fiber laser cutting machine?

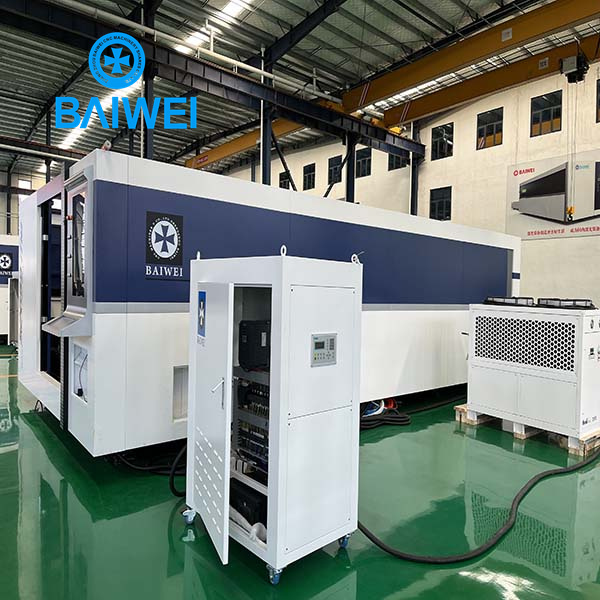

To select the appropriate power for fiber laser cutting machines, firstly needs to determine the actual processing material and cutting thickness. That is the machine power and working area.

Second, to ensure that the cutting surface is very smooth, that the cutting speed is fast, and that material deformation is minimal. A good manufacturer will suggest you choose a higher power of the fiber laser cutting machine. In a word, to select appropriate power for fiber laser cutting machines, needs to confirm Metal Sheet type, like mild steel , stainless steel, aluminum, copper, brass and so on. Then often Cutting Thickness and Maximum cutting thickness. To know these things, we will confirm which type of the laser power is suitable.

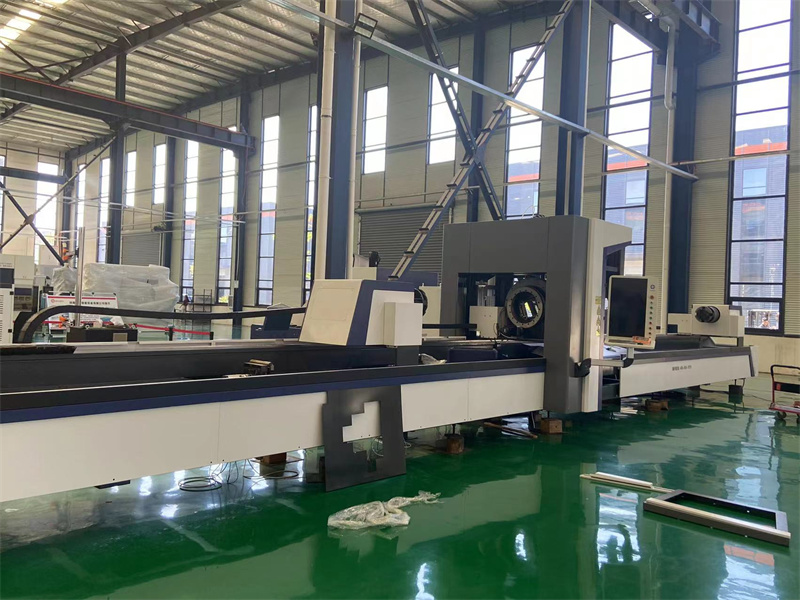

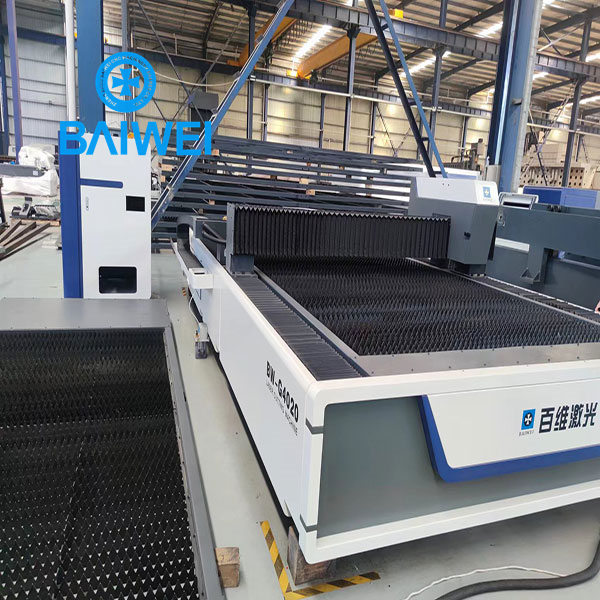

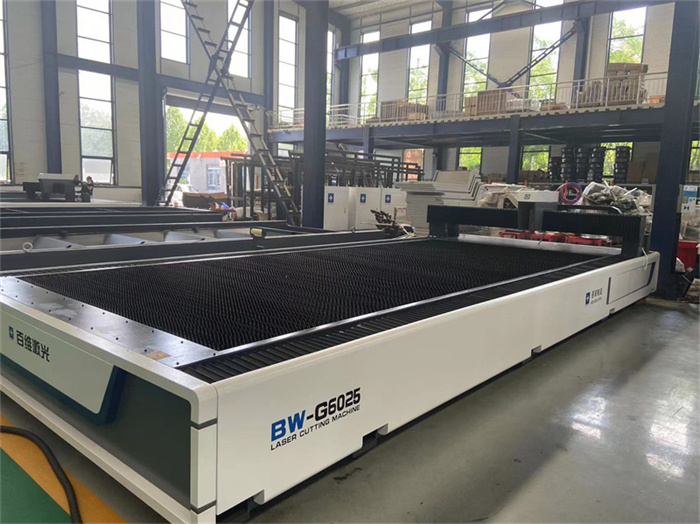

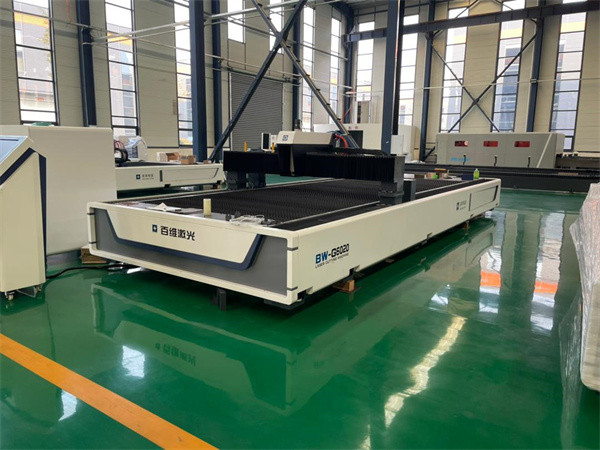

Cutting Area: 6*2.5 meters

Laser power: 8 kw

Cutting Thickness: up to 30mm

Working Voltage: 380v 50Hz/60Hz

Max acceleration: 2.5G

Moving Speed: 100m/min

Cutting Speed: 35-80m/min

Positioning Accuracy: 0.03mm

Repositioning accuracy: 0.02mm

The laser generator is the key of the fiber laser cutting machine, which determines the cutting capacity of the equipment.

And what you need is a high cutting speed and high cutting precision machine, that is the advantages of a fiber laser cutting machine.

The material and thickness do matter the watt of laser generator. Like that if you want to cut the carbon steel below 10 mm, then 2000–3000 Watt fiber laser cutting machine is better. The thicker needs higher laser power.