In the field of industrial manufacturing, laser cutting machines are widely used in all walks of life due to their efficient and flexible processing advantages, especially in metal processing, laser cutting machines have almost become a must-have tool for processing manufacturers.People are no longer unfamiliar with laser cutting machines, but many people know little about the principles of laser cutting machines. Today we will talk about the processing principle of fiber laser cutting machine, so that you have a basic understanding of fiber laser cutting machine.

Cutting principle

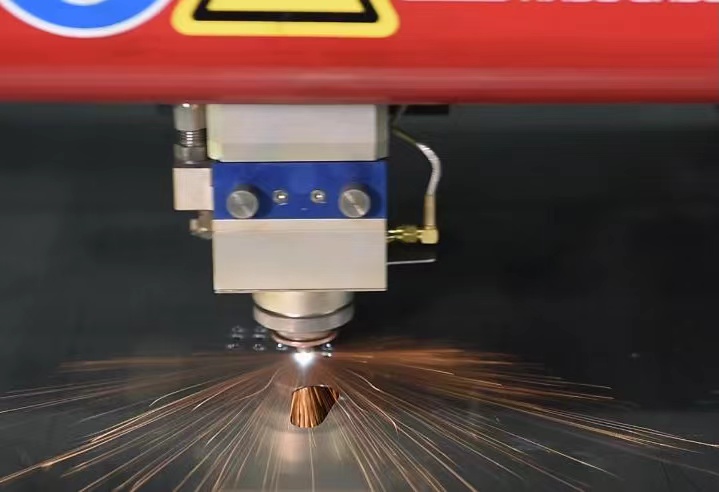

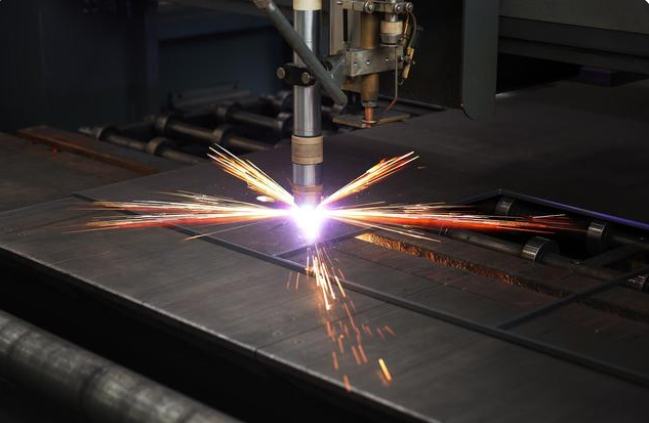

The basic principle of laser cutting is: focus the laser on the material, heat the material locally until it exceeds the melting point, and then blow the molten metal away with the coaxial high-pressure gas or the generated metal vapor pressure, as the beam moves relatively linearly with the material, Continue holes to form very narrow slits.

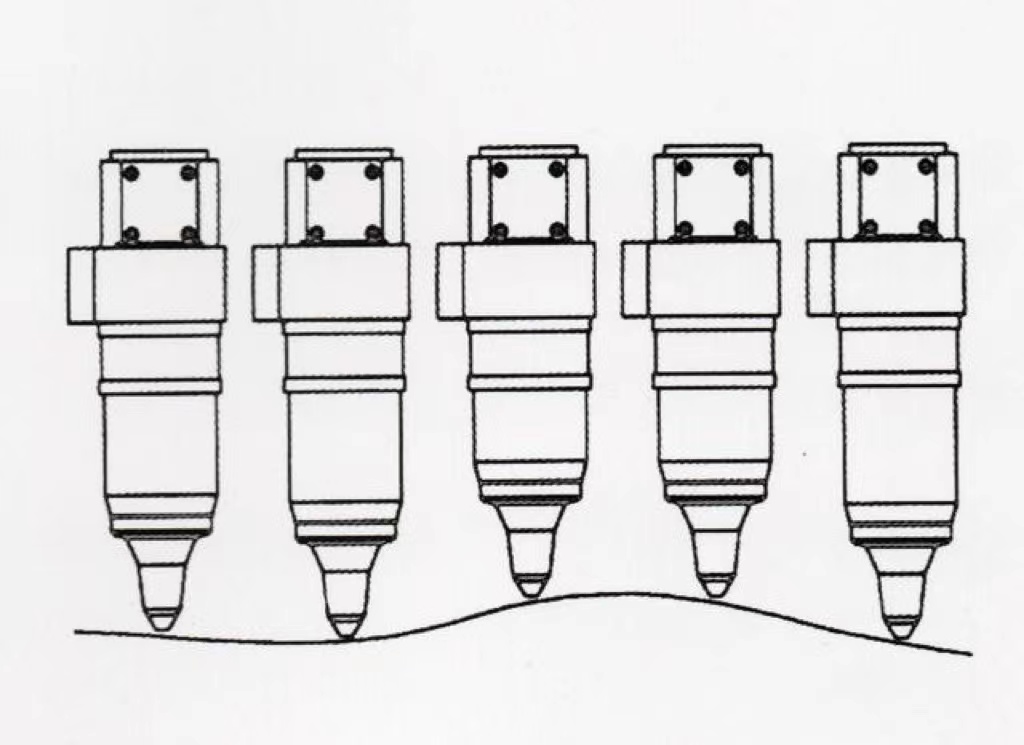

Follow-up system

In the large-format laser cutting machine, the processing height of different places is slightly different, which causes the surface of the material to deviate from the focal length, so that the size of the focused spot and the power density are different in different places, and the laser cutting quality of different cutting positions is very inconsistent , can not meet the quality requirements of laser cutting. The cutting head adopts a follow-up system to ensure that the height of the cutting head and the cutting material is consistent, thereby ensuring the cutting effect.

Auxiliary gas

During the cutting process, auxiliary gas suitable for the material to be cut must be added. In addition to blowing away the slag in the slit, the coaxial gas can also cool the surface of the machined object, reduce the heat affected zone, cool the focusing lens, and prevent smoke and dust from entering the lens holder and contaminating the lens and causing the lens to overheat. The choice of gas pressure and type has a great influence on cutting. Common gases are: air, oxygen, nitrogen.

Cutting process

The cutting process is related to the following factors: laser mode, laser power, focus position, nozzle height, nozzle diameter, assist gas, assist gas purity, assist gas flow, assist gas pressure, cutting speed, sheet speed, sheet surface quality.

Laser cutting is the energy released when the laser beam is irradiated on the surface of the workpiece to melt and evaporate the workpiece, so as to achieve the purpose of cutting and engraving. , low processing cost and other characteristics, will gradually improve or replace the traditional cutting process equipment.The price of laser cutting equipment is quite expensive, about 2 million yuan or more. However, since the cost of subsequent processing is reduced, it is still feasible to use this equipment in mass production. Since there is no tooling cost, laser cutting equipment is also suitable for producing small batches of parts of various sizes that were previously inaccessible. Laser cutting equipment usually uses a computerized numerical control technology (CNC) device, after which the cutting data can be received from a computer-aided design (CAD) workstation using a telephone line.