How can I get a laser cutting machine for metal?

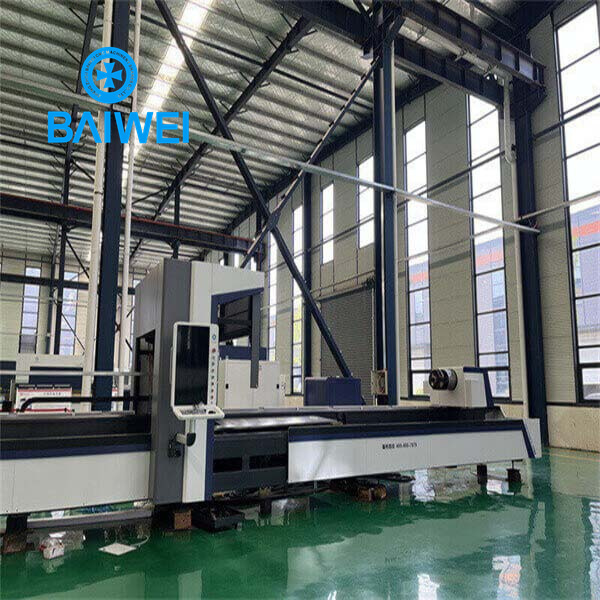

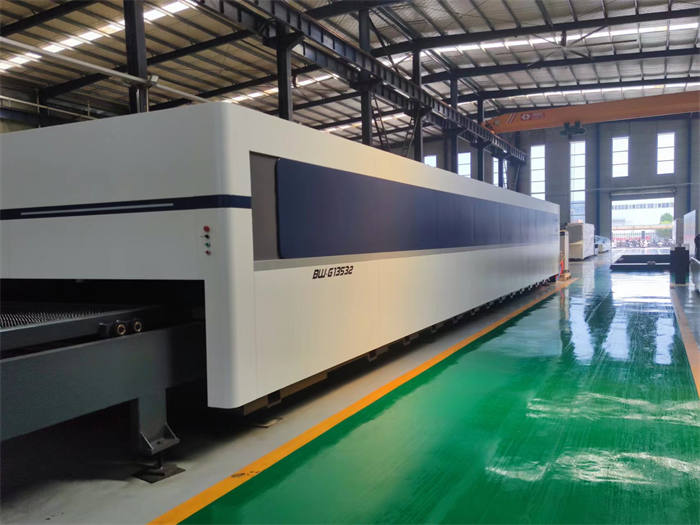

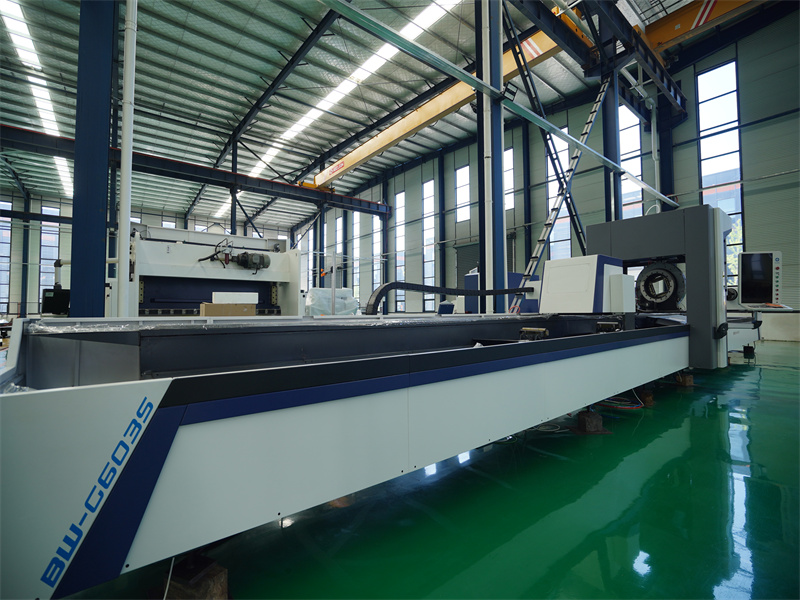

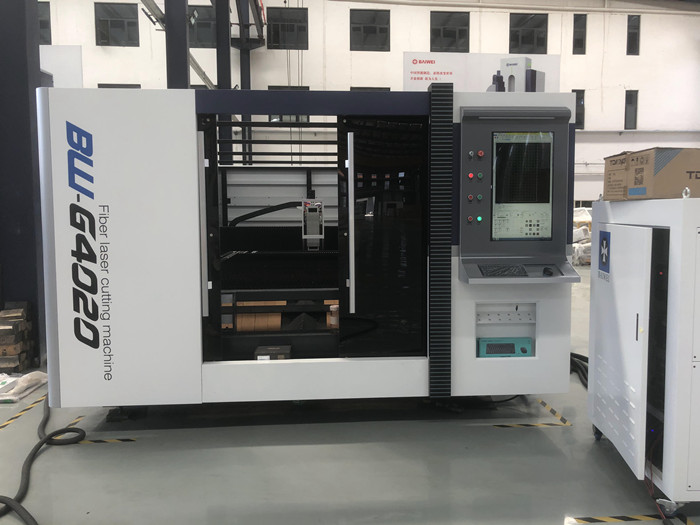

Model:BW-6025

cutting range:2.5*6m

Power:6kw

Max cutting speed:60m/min

Max idle speed:120m/min

positioning accuracy:0.03mm

Repeatability:0.02mm

Some important parts of the laser cutting machine, we also need to pay attention when purchasing. Laser generator, laser cutting head, servo motor, guide rail, etc., it is necessary to distinguish whether it is domestic or foreign. These parts all directly affect the cutting speed and precision of the laser cutting machine.

Laser cutting machine is composed of laser generator, cutting head, beam transmission assembly, machine tool table, numerical control system and cooling system.

Laser generator: A laser generator is a component that generates a laser light source. For metal cutting, fiber laser generators are commonly used at present. Since laser cutting has very high requirements on the laser light source, not all lasers are suitable for the cutting process.

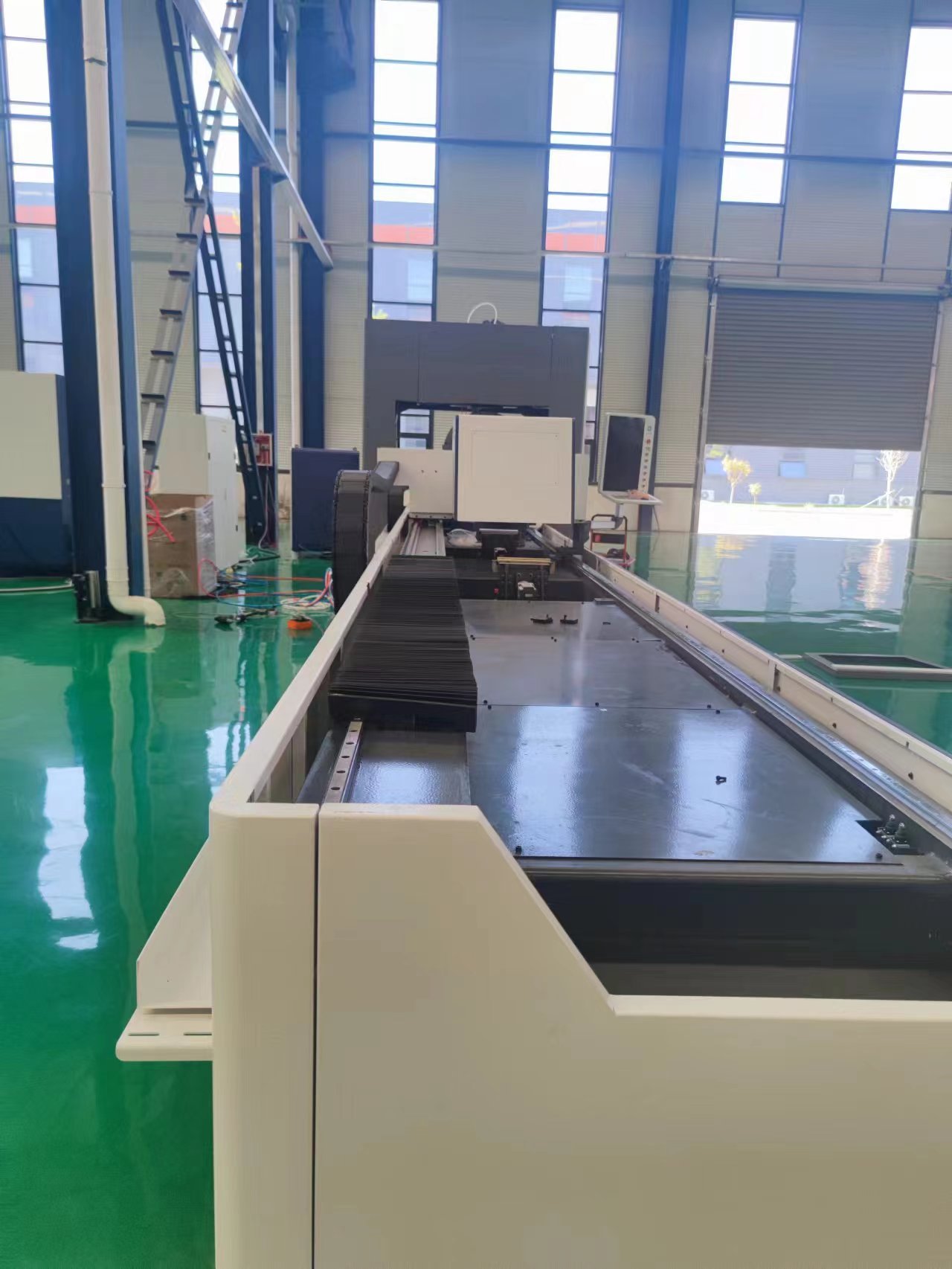

Cutting head: The cutting head is mainly composed of nozzle, focusing lens and focus tracking system.

Beam Delivery Assembly: The main component of the beam delivery assembly is the refractive mirror, which is used to direct the laser light in the desired direction. The reflector is usually protected by a protective cover, and a clean positive pressure protective gas is introduced to protect the lens from contamination.

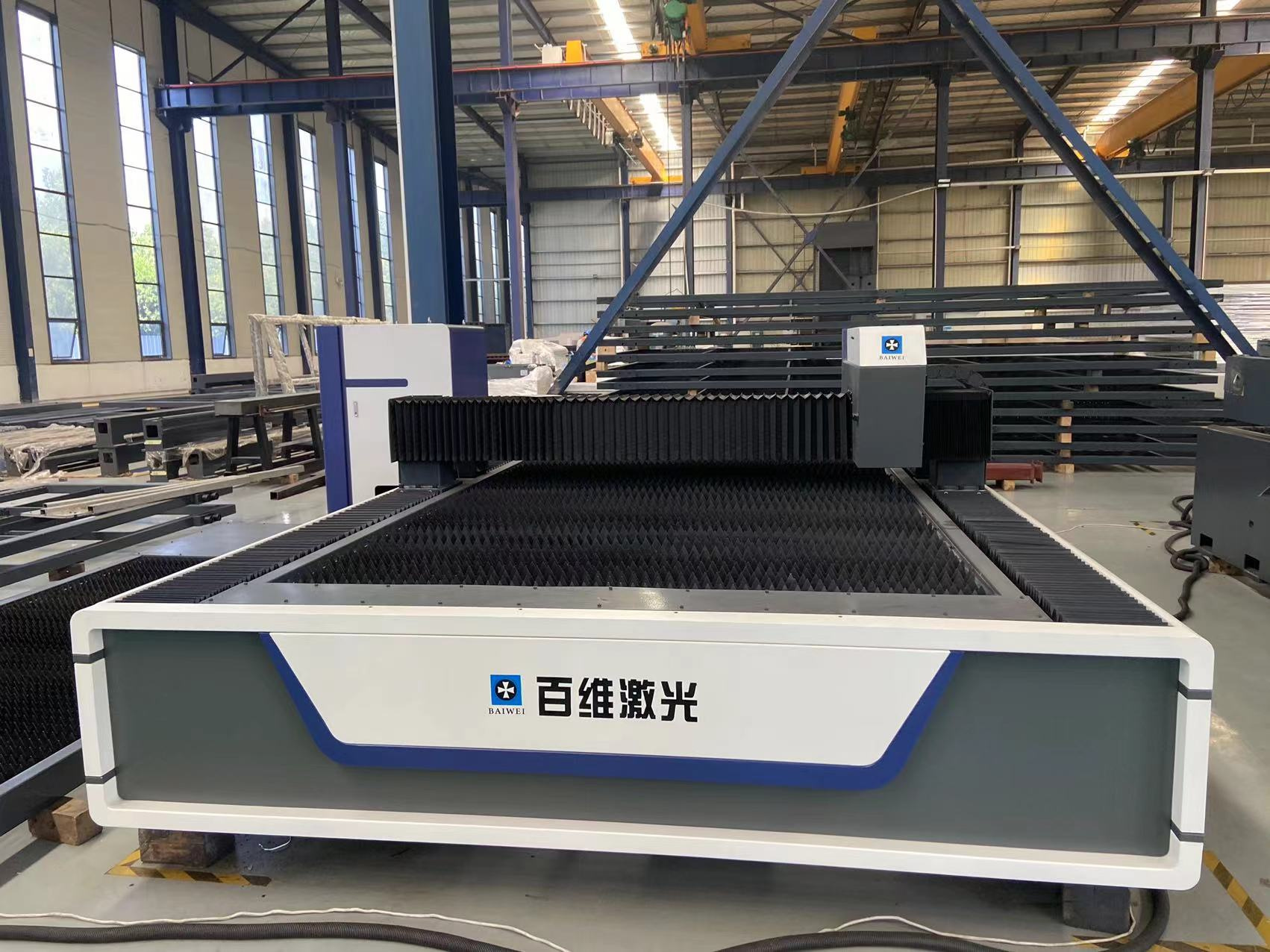

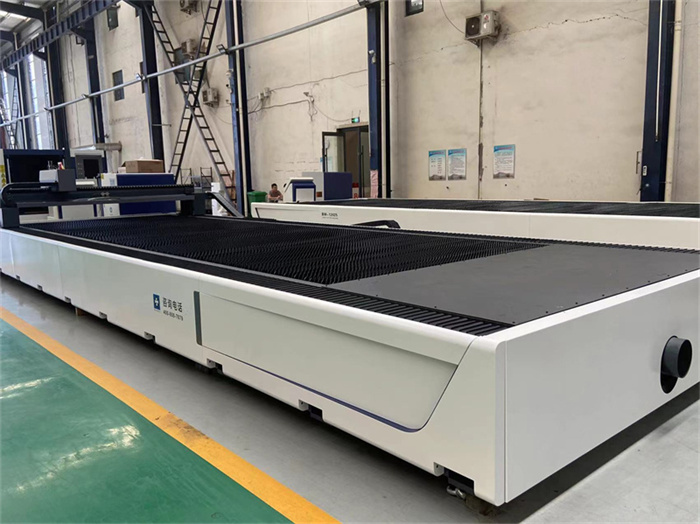

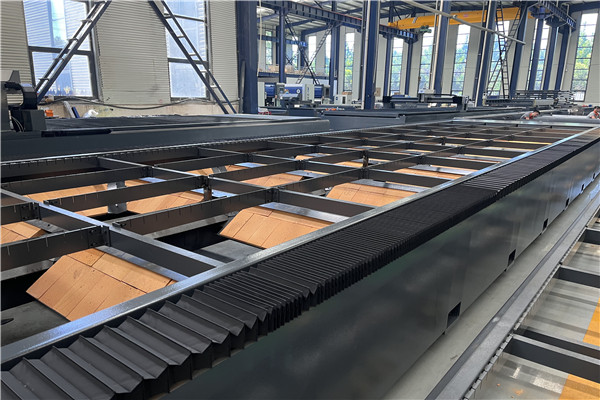

Machine tool table: The machine tool table is mainly composed of the weighing bed and the driving part, which is used to realize the mechanical part of the X, Y, Z axis movement, and also includes the cutting table.

CNC system: The CNC system can mainly control the movement of the machine tool to the X, Y and Z axes, and can also control parameters such as power and speed during cutting.