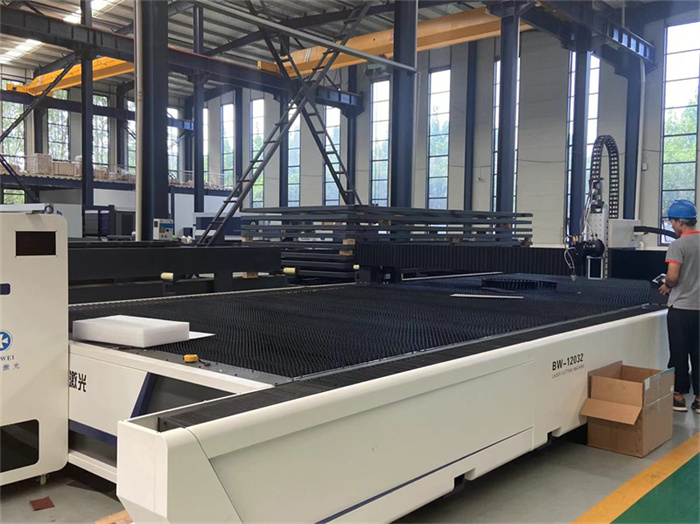

Hot sale metal laser cutter 3kw for stainless steel

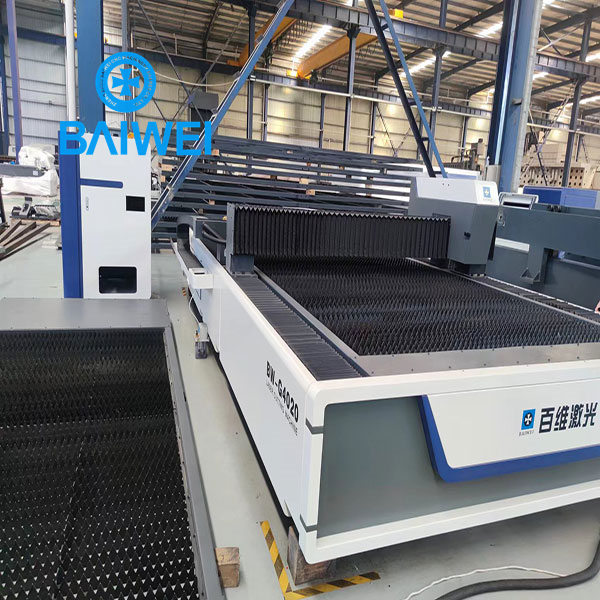

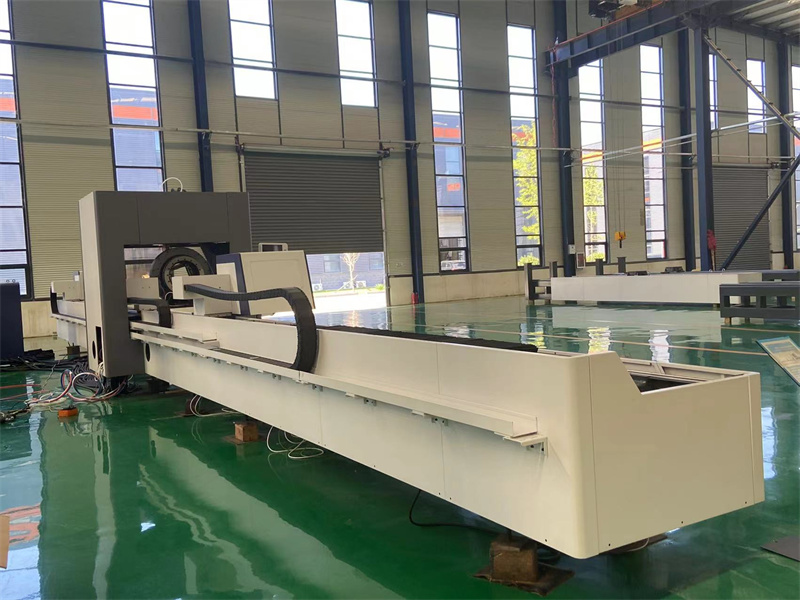

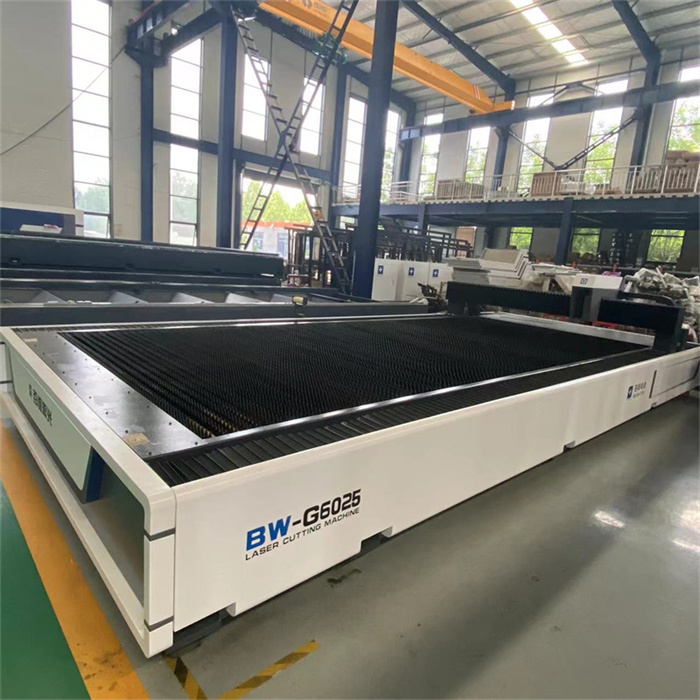

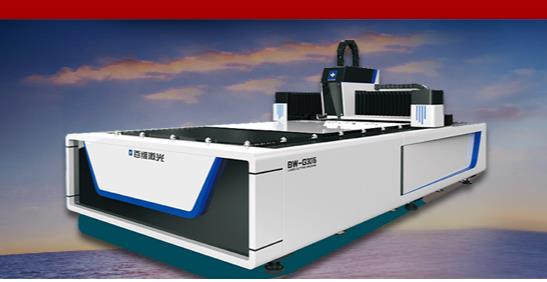

High-speed laser cutting machines are generally widely used in sheet metal processing, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, construction machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration , advertising, metal external processing, kitchen utensils processing and other manufacturing and processing industries.Model:BW-G12032

Laser Power£º6kw/8kw/10kw/12kw

Max.moving Speed:100m/min

Max.cutting Speed:60m/min

Positioning accuracy:0.03mm

Re-position accuracy:0.02mm

Min.line Width:0.1mm

The lightweight and slender design enables it to obtain fast acceleration performance and cutting speed. The servo motor ensures precision, and the cutting is performed again and again. Unlike other factories, the details determine the quality. The laser cutting machine has a professional laser cutting numerical control system, which can automatically find edges and automatically discharge materials to improve the utilization rate and production efficiency of plates.Not only does laser cutting work on a large number of metals, but it is a universal tool among industries. Laser cutting can result in cleaner, smoother, tighter cuts than machining. Like machining, it can also be programmed and directed by a computer, which means that laser cutters can automatically make a large number of metal parts for industries like automobiles, computers, and more. Often, odd shapes like car frames or hydroformed parts require laser cutting, as do many parts in the aerospace industry, and the results are often better than plasma cutting.