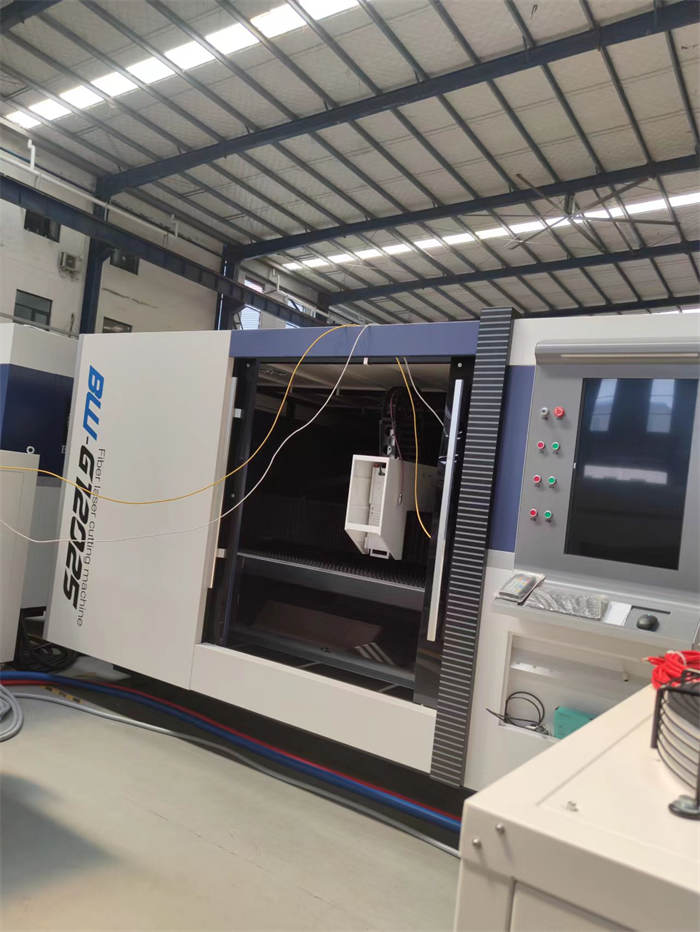

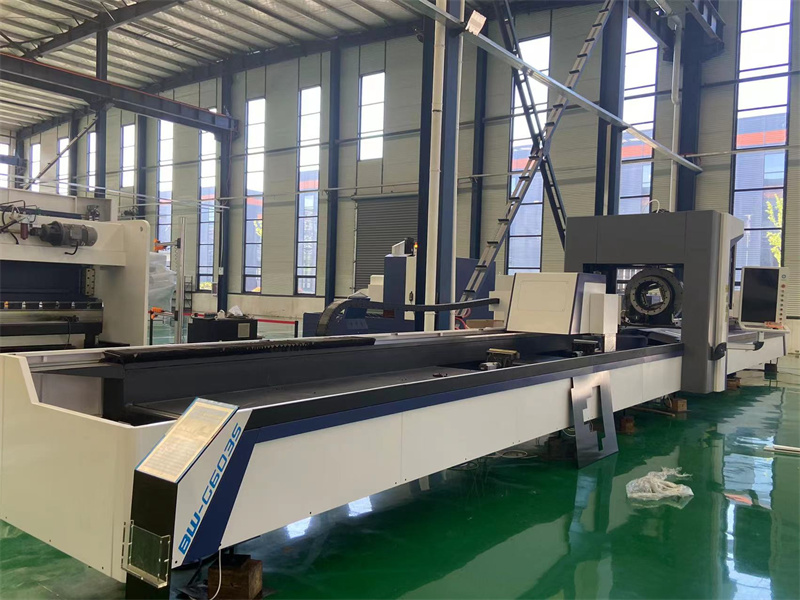

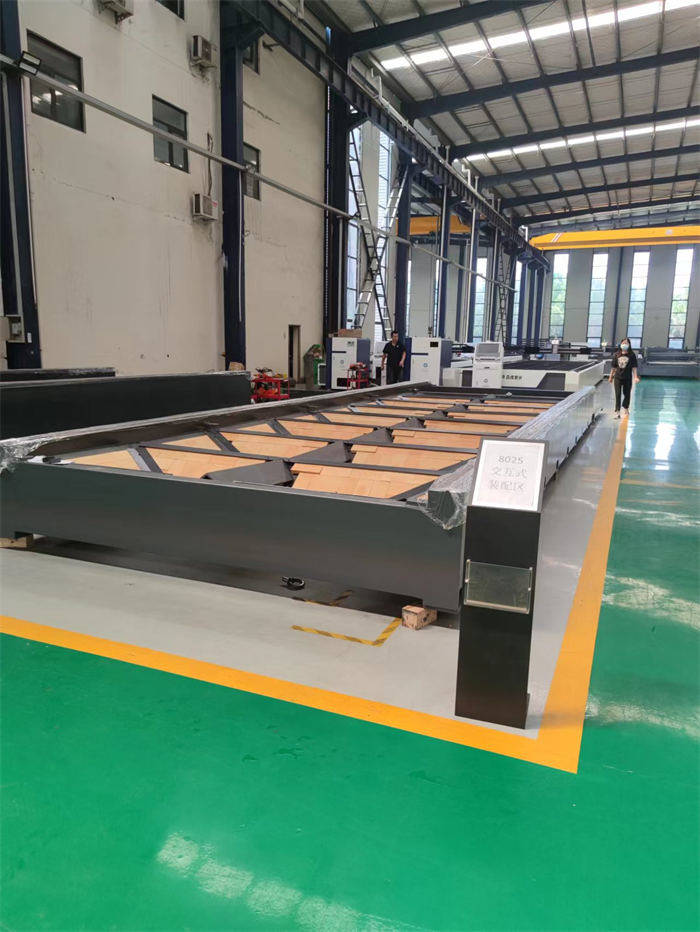

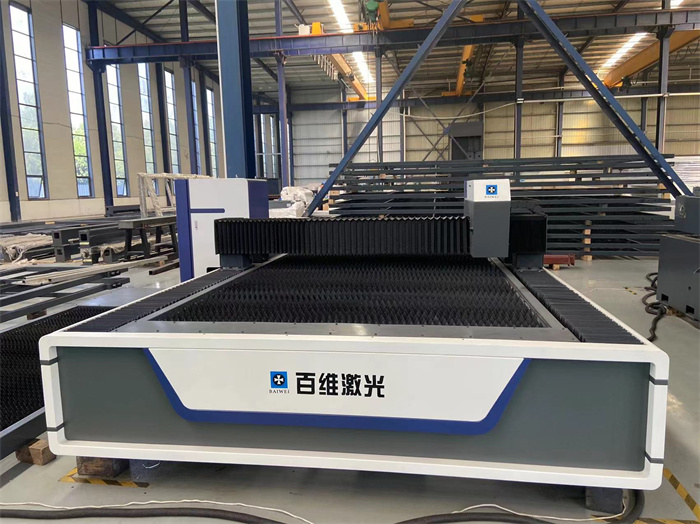

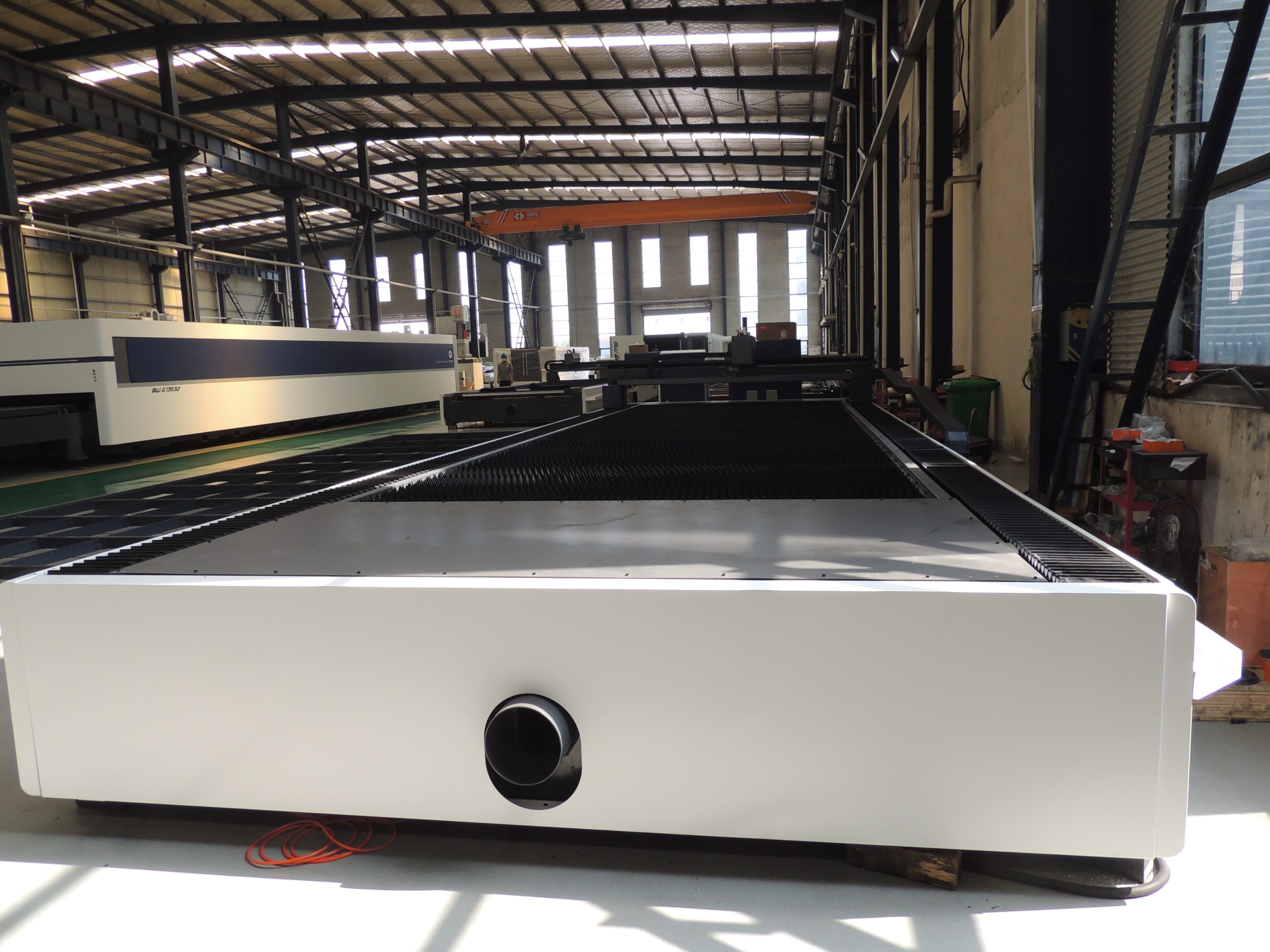

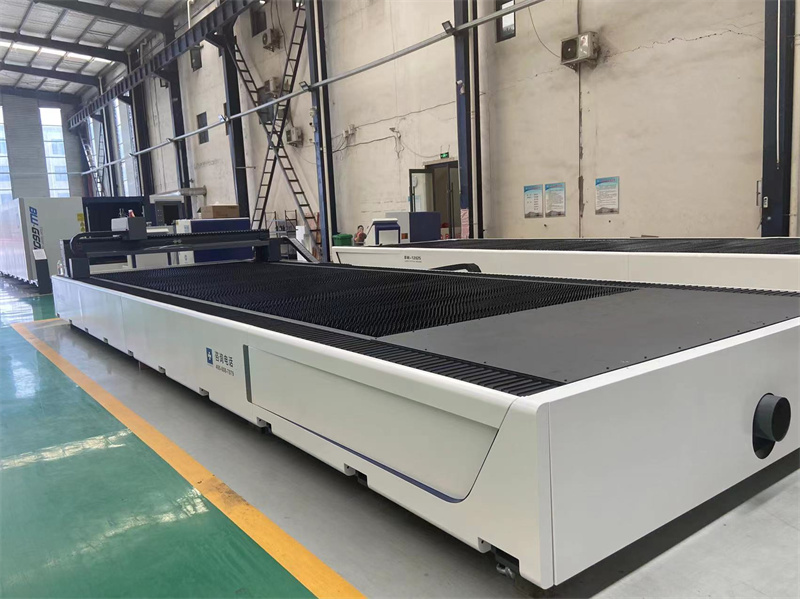

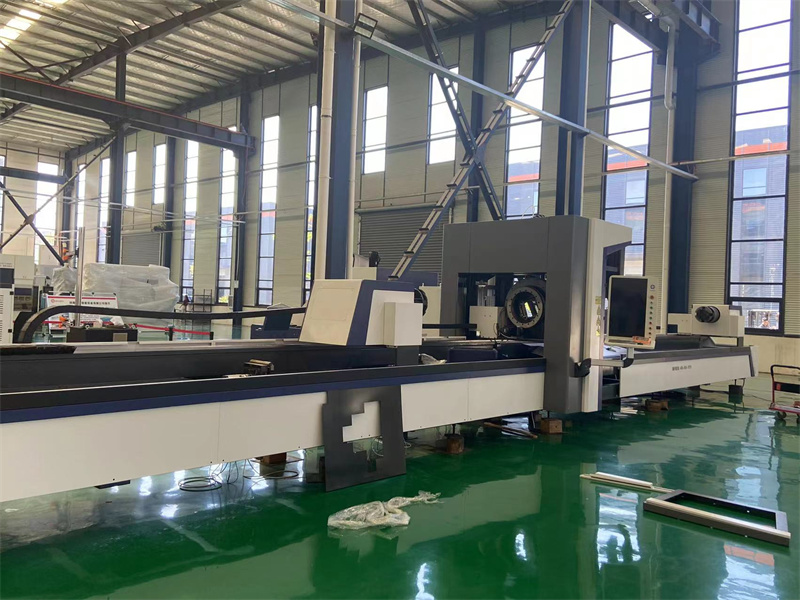

High speed and warranty professional tube laser cutting machine

The professional tube laser cutting machine has high cutting efficiency and can realize mass production. The professional tube laser cutting machine is beneficial to the subsequent automatic welding.

Laser Type:Fiber Laser Source

Max. Output Power:500W/800W/1000W/1500W/2000W

Effective Pipe Cutting Diameter:¡Ü220MM

Effective Pipe Cutting Length:3000MM/6000MM

Workable Axis Positioning Accuracy:¡Ü¡À0.05MM

What type of laser is best for cutting through metal?

Metal laser cutting does not rely on pure laser power in cutting process. There is another factor that takes into play such as the wavelength of the laser. Somehow the shorter the laser wavelength, the finer the cutting. Fiber laser has 1064nm while CO2 laser has 10640nm wavelength. Certain metal does not react really well with 10640nm wavelength.

Assist gas is an important factor in multiplying cutting prowess and getting desired result. Oxygen assisted cut (OAC) is very effective method for laser cutting as Oxygen will react with metal and will ease the cutting process at drawback of blackened result. Nitrogen assist gas will effectively made the laser cutting weaker as nitrogen it is inert gas. Inert gas will however, prevent the material from oxidising therefore cutting using pure ablation.

At this moment, fiber laser cutting would be the best. It provides good cutting result and generally requires lower power compared to CO2 laser at same thickness and are generally produces finer cut.

500w Fiber Laser can cut 5mm steel with oxygen assist gas and around 2mm steel with nitrogen, while 150w CO2 laser can cut 1.2mm steel with oxygen assist gas and can¡¯t cut any metal with nitrogen assist gas. You can see that actually the CO2 laser is making OAC process and the fiber laser is actually ablating the material.

Higher power CO2, while can rival fiber laser performance, is generally a lot more expensive to both operate and purchase.