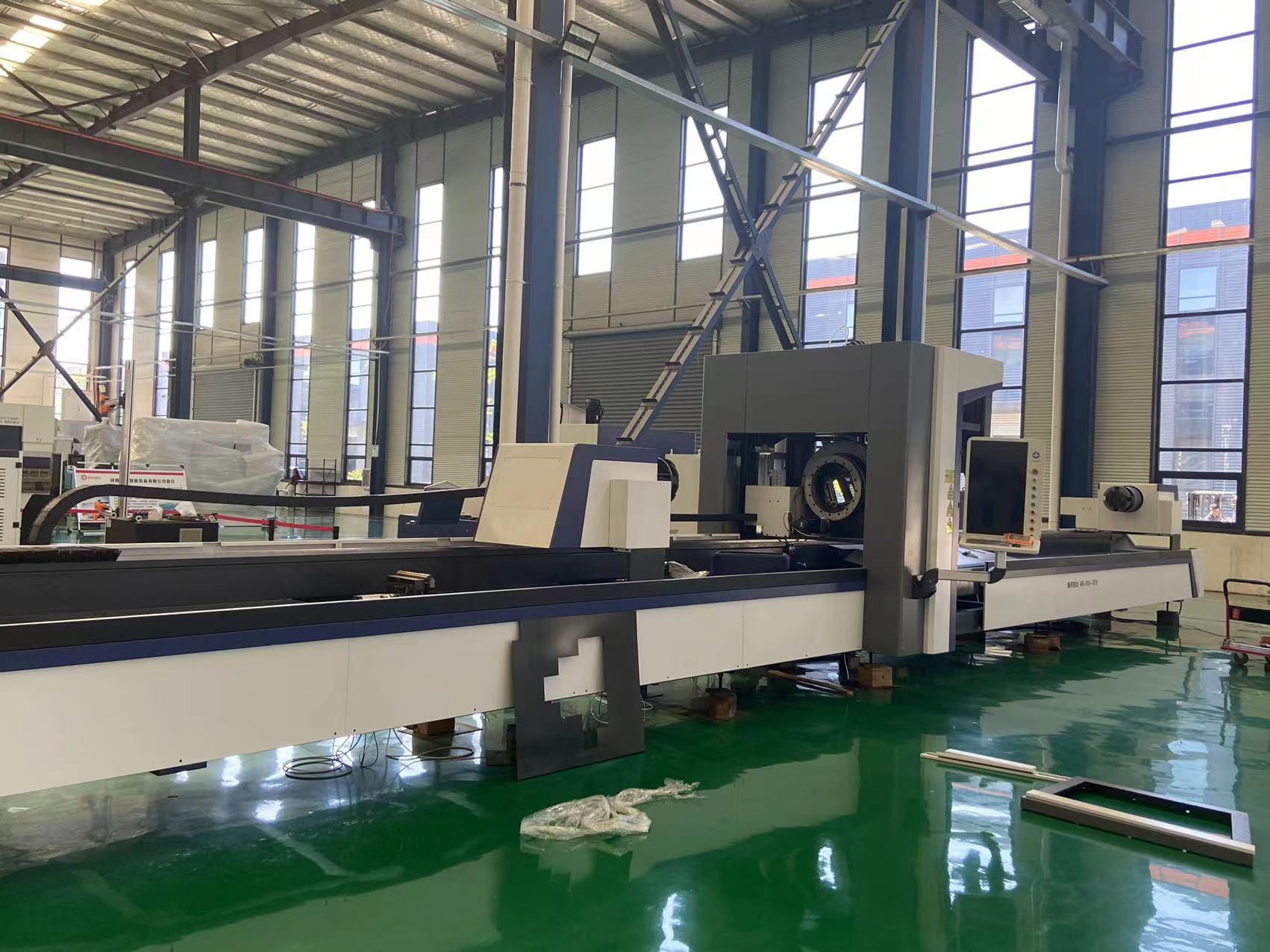

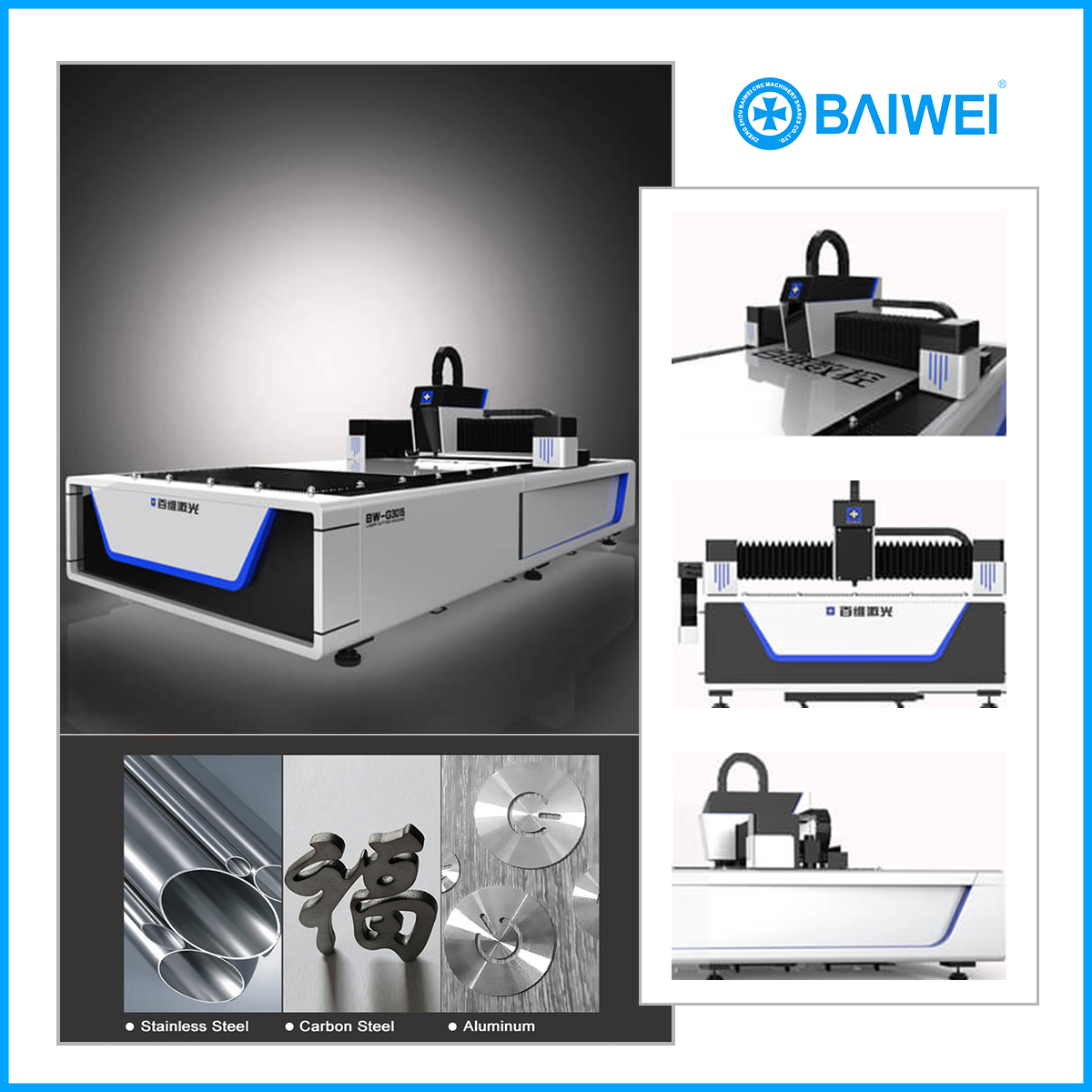

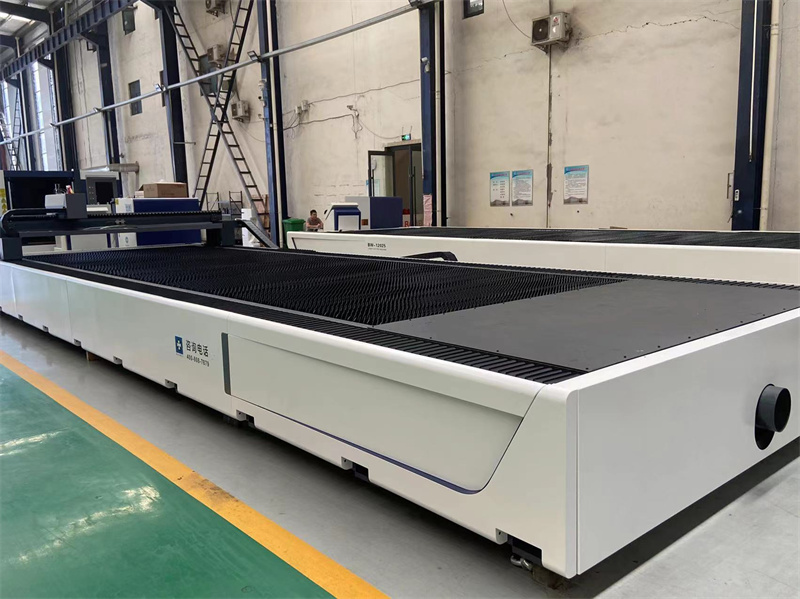

High-precision professional tube laser cutting machine with guaranteed quality

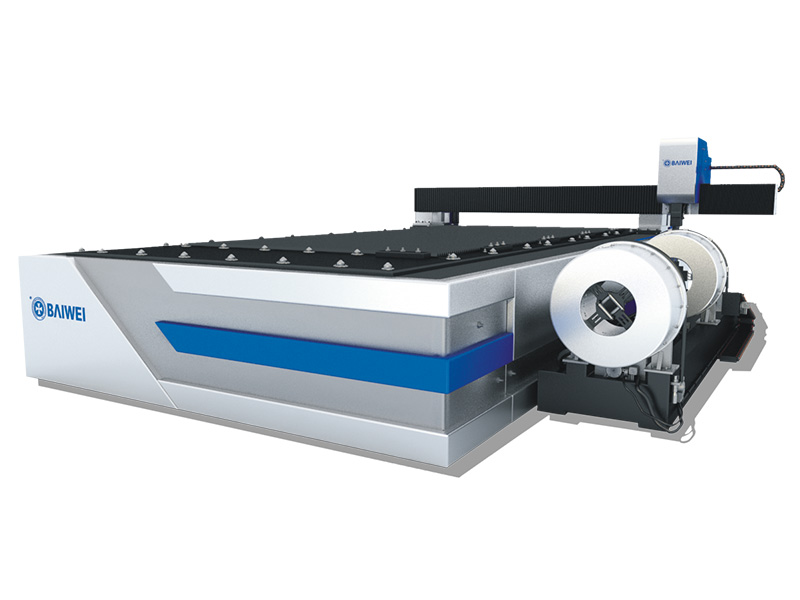

The professional tube laser cutting machine does not need to generate gas during the laser generation process. The professional tube laser cutting machine adopts air-assisted cutting, optical fiber transmission, and does not need to adjust the optical path.

Laser Type:Fiber Laser Source

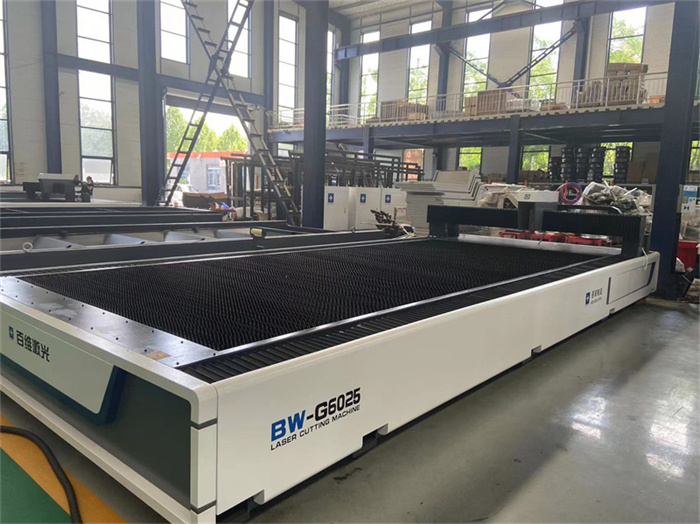

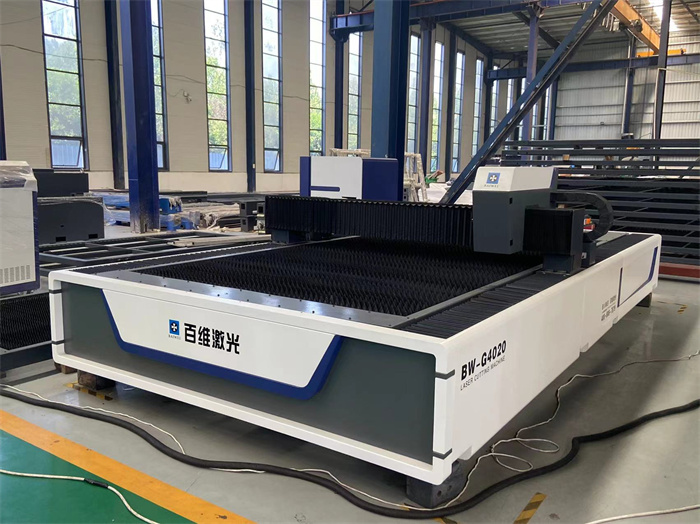

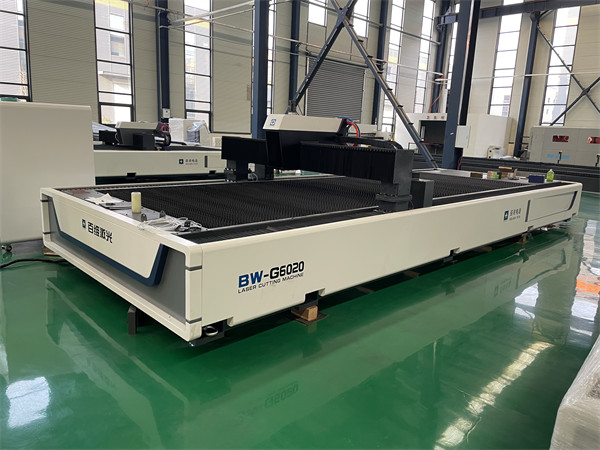

Max. Output Power:500W/800W/1000W/1500W/2000W

Effective Pipe Cutting Diameter:¡Ü220MM

Effective Pipe Cutting Length:3000MM/6000MM

Workable Axis Positioning Accuracy:¡Ü¡À0.05MM

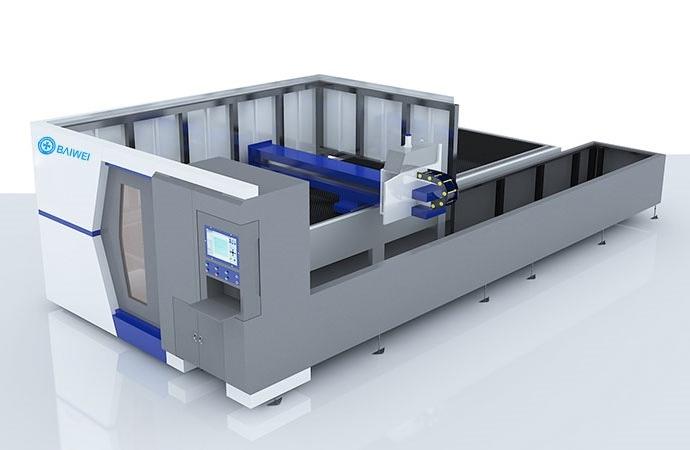

Have you ever noticed the structure of the cutting head?

It is composed by 13 parts, including artifact, nozzle, oxygen intake pipe, nitrogen pressure gauge, lens cooling water jacket, focusing lens, laser beam, reflector, reflector cooling water jacket, servo motor, ball screw, amplication control and drive motor and position sensor.

Laser beam is reflected by the reflector, and then it would pass through the focusing lens and nozzle, arriving at the surface of the metal sheet or pipe. In addition, nozzle plays a critical role in the process of cutting and engraving. The laser head could avoid to be polluted by slag produced during the cutting since the nozzle could produce air while operating the machine.

It is true that laser is the brightest light source in the world, hydrogen bomb could compare with it only at the moment of explosion. According to the scientific data, the brightest of sunshine is about 103 watt square centimetre, while the output brightness of a high power fiber laser generator cold exceed 7 to 14 magnitude.

That is the reason why optical laser could easily reach the ultra-high temperature and high pressure at the part of material.