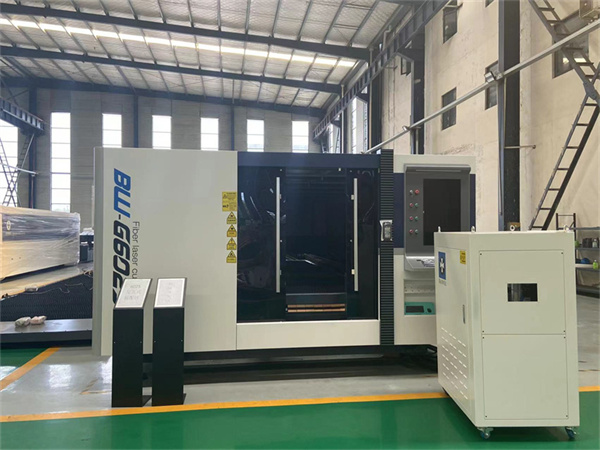

High-precision and warranty professional tube laser cutting machine

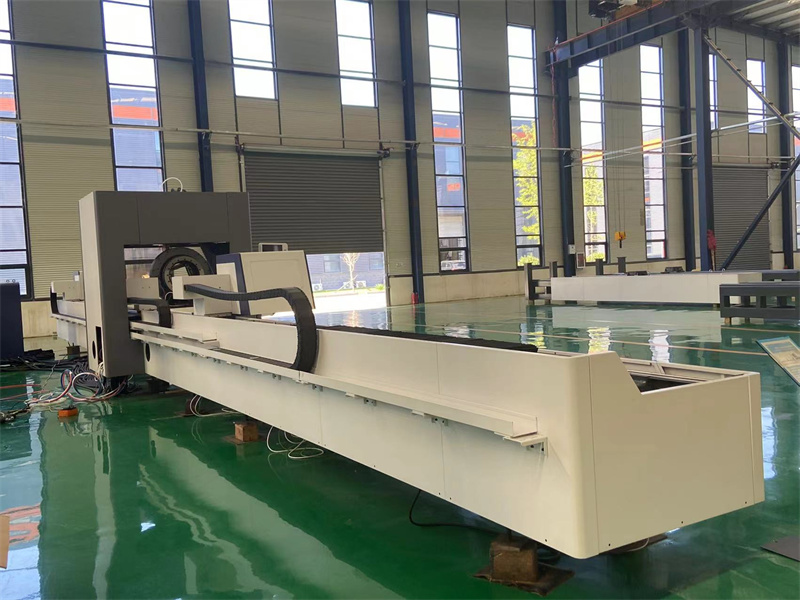

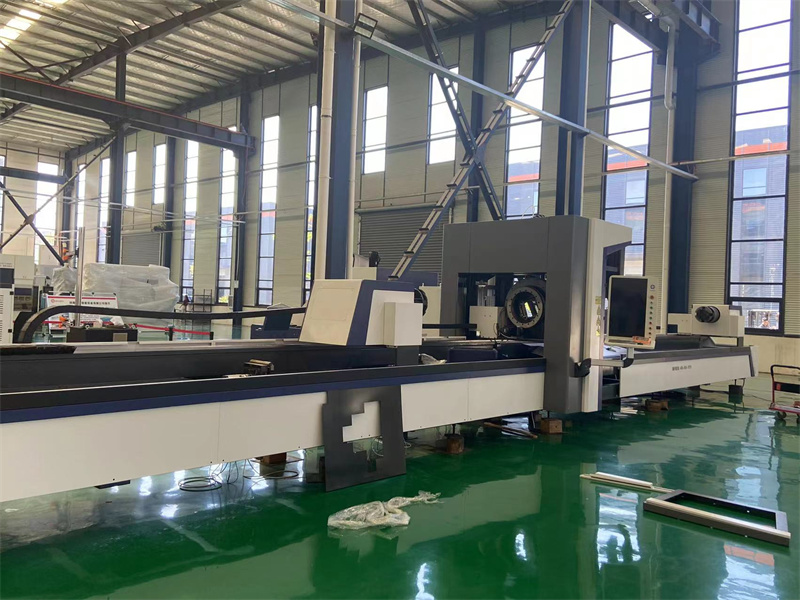

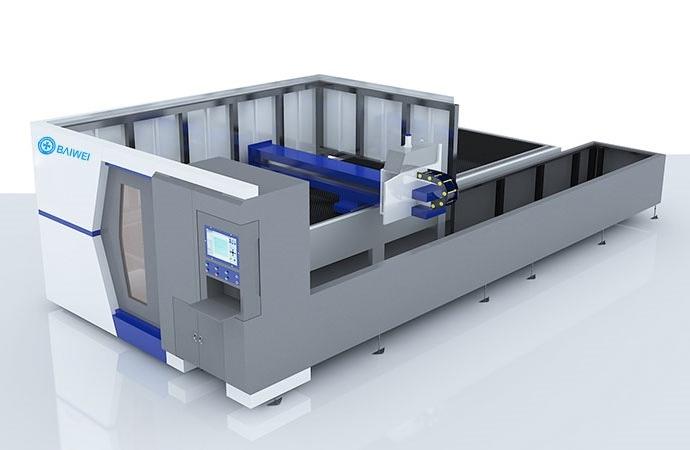

The professional tube laser cutting machine has high precision, high speed and narrow slit. In addition, the professional tube laser cutting machine has a small heat-affected area and a smooth cut surface without burrs.

Laser Type:Fiber Laser Source

Max. Output Power:500W/800W/1000W/1500W/2000W

Effective Pipe Cutting Diameter:¡Ü220MM

Effective Pipe Cutting Length:3000MM/6000MM

Workable Axis Positioning Accuracy:¡Ü¡À0.05MM

In the 1990s, elevator components were basically made of multi-station stamping plates. For safety reasons, elevator components are basically made of metal. The development trend of elevators is mainly high-speed elevator technology, intelligent control, and efficient cleaning. With the emergence of several world-renowned brand elevators, imported laser cutting machines were introduced into domestic sole proprietorships or joint ventures, and later laser cutting machines began to be used in the domestic elevator industry. With the emergence of domestic laser cutting equipment manufacturers, the situation that laser equipment can only rely on imports has been broken, and it has been put into use in the elevator manufacturing industry, which has reduced the expensive price of elevators a lot. Therefore, domestic elevator companies and accessories companies have chosen to purchase laser cutting machines for production.

Taking elevator sheet metal processing as an example, more and more manufacturers choose laser cutting machines as their primary productivity to process components such as fish-shaped panels, elevator door panels, escalators and supporting doors in elevator sheet metal manufacturing. In the past, elevator sheet metal processing involves the design of molds. The mold design is complex, the production cycle is long, it is very laborious, and the economic cost is also high. Therefore, most companies currently use laser cutting machines to complete elevator sheet metal processing, because The laser cutting machine is not limited by the mold, and the cutting range and form are very flexible. Even if there is no mold, it can achieve high-speed cutting of sheet metal, which greatly shortens the processing time and reduces the processing cost.