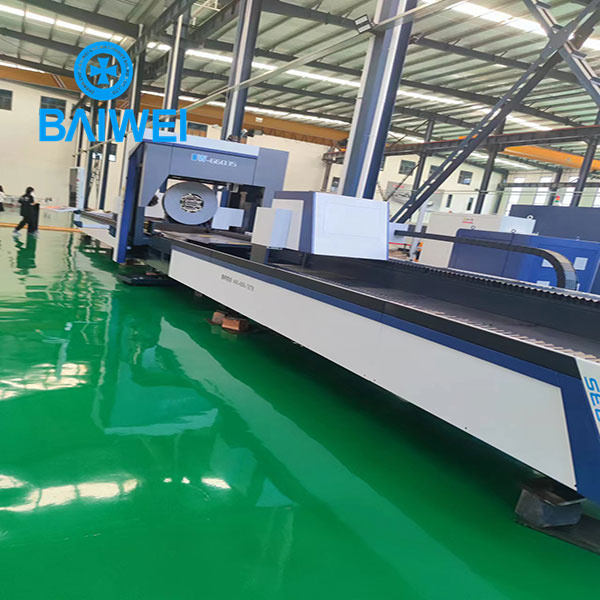

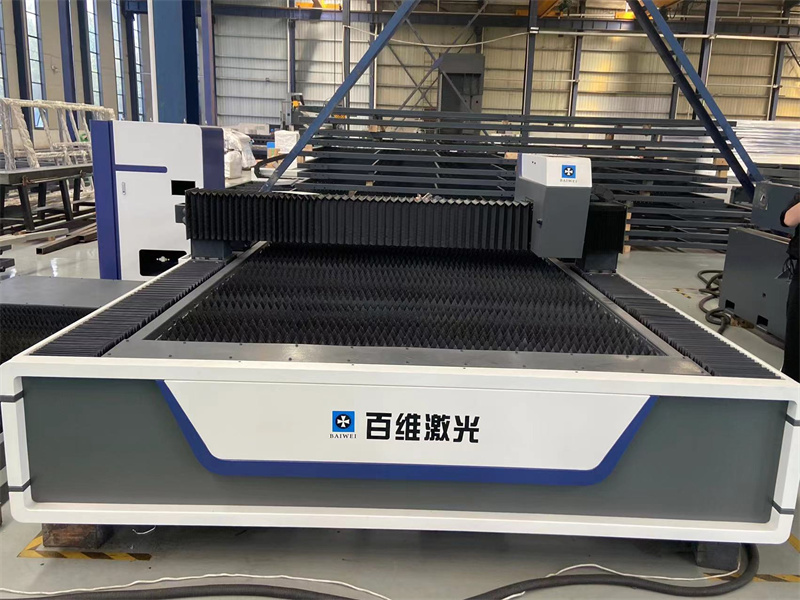

Fiber laser pipe cutting machine manufacturers for Subway accessories industry

For some porous workpieces, use the dot function of the laser pipe cutting machine to determine the position of the hole, which saves the time for positioning the hole and the manufacturing cost of the drilling template in the subsequent drilling process, which not only improves the production efficiency, but also improves the quality of the product. precision. Model:BWQG6016-6000*160 professional tube laser cutting machine

Power:3kw/4kw/6kw/8kw

Cutting diameter: ¡Ü499mm

Cutting length: 6000mm/9000mm/12000mm

cast iron bed

The flake graphite of the cutting bed greatly improves the shock absorption and wear resistance, and the residual stress almost disappears after age hardening, thus improving the precision and life of the equipment and saving costs.

Bevel cutting

The ¡À45¡ã groove cutting realizes the seamless splicing of pipes and meets the high-quality cutting requirements of groove welding of medium-thick pipes.

Steady Flow Throttle Nozzle

By maintaining a steady airflow with little to no turbulence, cutting performance and efficiency are improved.